Umshini Welding Ophathwayo We-Fiber Handheld Laser

Incazelo Yomkhiqizo

Izinhloso zokukhiqiza umshini wokushisela we-laser ophathwa ngesandla, unezinga eliphakeme lezinzuzo zemboni yobungcweti, kuyilapho uqinisekisa ukushiselwa kwezinhloso ezinembile zokuqinisekisa inqubo, kodwa futhi nokufeza ukwakheka okusebenzayo nokusebenzayo kobuntu.

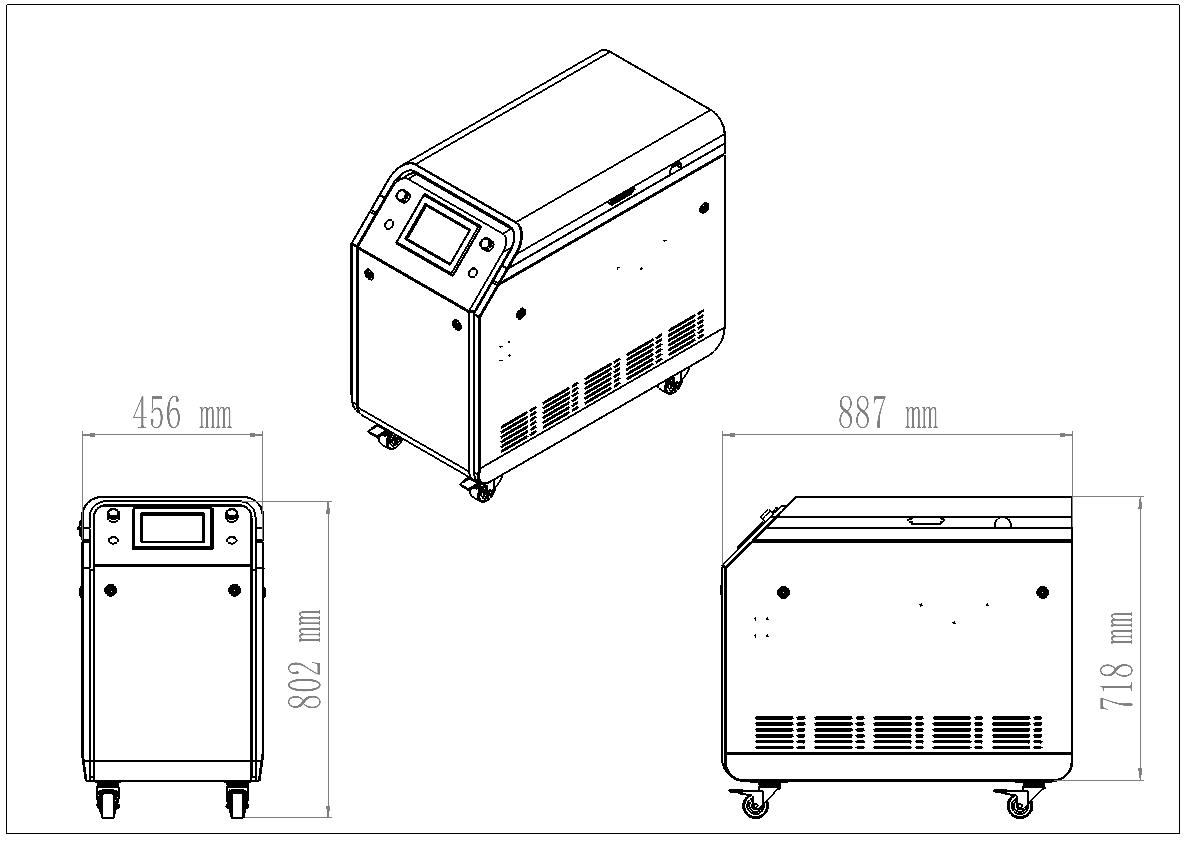

| Usayizi Womshini: | |

| Ubude | 456 mm |

| ububanzi | 887 mm |

| Ubude | 718 mm |

| 1.Ikhabhinethi incane futhi inhle2. Nge-silky pulley ebushelelezi 3. Ikhabethe elimhlophe Ngekhava ephephezelayo | |

Izici nezinzuzo zomshini we-laser welding ophathwa ngesandla:

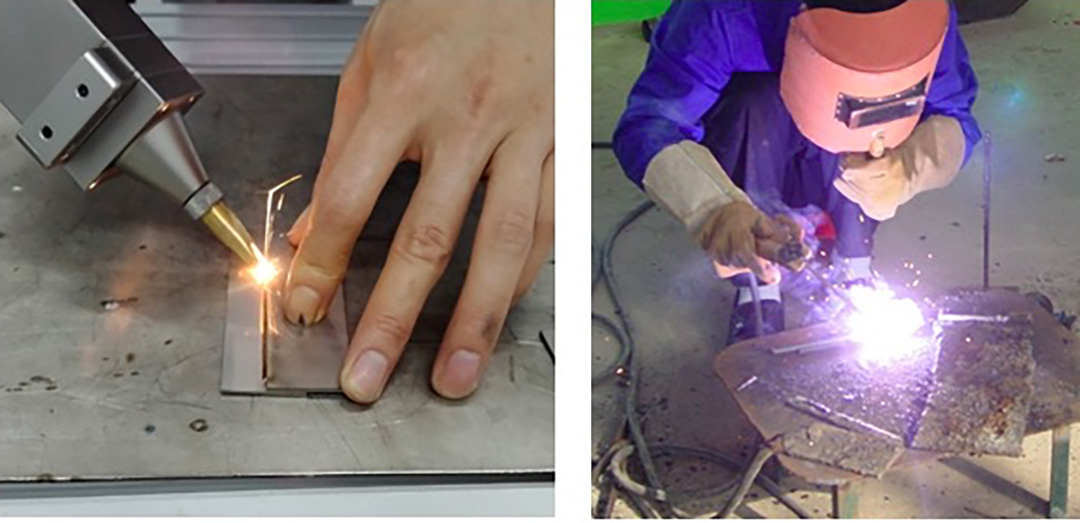

umshini wokushisela we-laser welding gun esikhundleni sendlela yendabuko engaguquki ye-optical, eguquguqukayo futhi elula ukuze kuzuzwe ukushiswa kwe-laser okude, ukunqoba ukulinganiselwa kwendawo yokuhamba yetafula;

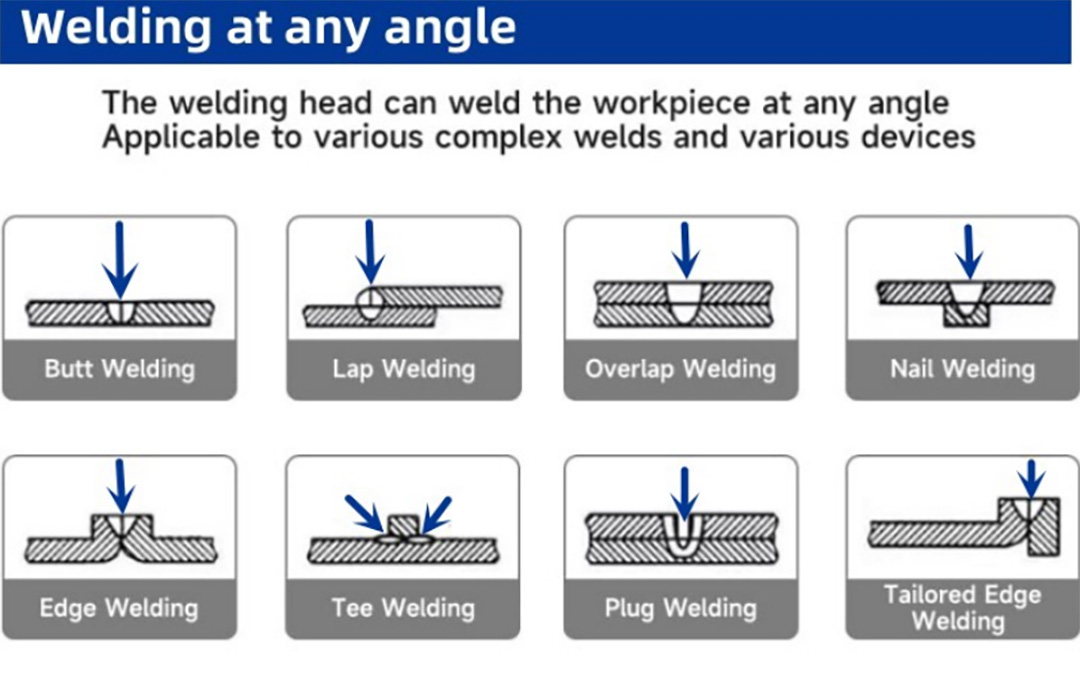

ephathwayo Welding ikhanda kuyinto engasindi futhi nezimo, kulula ukusebenza, ukuhlangabezana ezihlukahlukene engele, ezihlukahlukene izikhundla Welding, ingagcwaliswa phezu workpiece izingxenye ngokungenasizathu iphuzu kokubonisana kokubonisana welding, ebucayi futhi elula, can. i-welding yangaphandle ephelele, ilungele ukushisela okuhlukahlukene okungcolile, ukushisela amabala kwamadivayisi ahlukahlukene.

Ikhanda lokushisela eliphathwa ngesandla lifakwe amamitha ayi-10 wefiber optical engenisiwe, eguquguqukayo futhi elula ukufeza ukushisela ngaphandle. Ingakwazi ukufeza noma yikuphi ukushisela i-engeli kucezu lokusebenza, ukushintshwa okuhlakaniphile kwendlela yokubona okukabili, iyunifomu yokusabalalisa ukukhanya kokwabelana ngesikhathi.

Umshini wokushisela we-laser ophathwa ngesandla wamukela ukuma kwe-infrared, okusetshenziselwa ukukala indawo yekhanda le-welding kanye nokuqinisekiswa kwesikhundla lapho ushisela, indawo yokushisela inembe kakhudlwana ukuze kuqinisekiswe ukushisela okuhle kakhulu.

Izindleko zokulungisa eziphansi:I-laser welding ephathwa ngesandla, alikho itafula lokushisela elihle, impahla ephansi, ukusetshenziswa kwamandla okuphansi, ukuthunyelwa kwemishini ephansi kanye nezindleko zokuyilungisa. Endaweni efanayo yokusebenza, sidinga ukuchitha isikhathi esiningi ukuze sigcine itafula lokushisela, kuyilapho ukusethwa kwe-laser manual kanye nokuthunyelwa kwemishini kungasebenza inqobo nje uma kufakwe i-laser welding ephathwayo. Ngokuqondene nokushintshaniswa, izindleko zezesekeli ziphansi.

| Uhlobo | I-Argon arc welding | I-YAG eqinile | I-Laser Handheld Welding | |

|

Ikhwalithi yokushisela | Okokufaka kokushisa | Okukhulu | Encane | Encane |

| Ukuwohloka kwengcezu yokusebenza/ukuququda komphetho | Okukhulu | Encane | Encane | |

| Ukwakhiwa kwe-seam ye-weld | iphethini yesikali sezinhlanzi | iphethini yesikali sezinhlanzi | Bushelelezi | |

| Ukwelashwa kokulandelela | Kudingeka ukupholisha | Kudingeka ukupholisha | Lutho | |

| Sebenzisa Ukusebenza | Isivinini sokushisela | Kancane | Maphakathi | Ngokushesha |

| Ubunzima bokusebenza | Okukhulu | Encane | Encane | |

| Ukuphepha Kwemvelo | Ingozi yomuntu siqu | Okukhulu | Encane | Encane |

| Ukungcoliswa kwemvelo | Okukhulu | Encane | Encane | |

| Izindleko Zokusetshenziswa | Izinto ezisetshenziswayo | Induku yokushisela | Amakristalu e-laser, amalambu e-xenon | Lutho |

| Ukusetshenziswa kwamandla | Encane | Okukhulu | Encane | |

| Indawo yaphansi | Encane | Okukhulu | Encane | |

Ukucaciswa

| Imodeli No. | I-MLA-W-H1000G |

| Igama Lomkhiqizo | Umshini wokushisela i-fiber laser ophethwe ngesandla |

| Ubude begagasi | 1080+/-10 nm |

| Amandla e-laser | 1500W,1000W |

| Ukulungiswa kwamandla | 10~100% |

| Ububanzi bendawo ye-Laser | I-QCS 3±0.5/RFL-QCS 5.5±0.5 |

| Ubude befayibha | Standard 15m noma ucacise |

| Izindlela zokusebenza | Imodi ye-CW/Pulse |

| Ibanga lesivinini | 0 ~ 120mm |

| Ukuqina kwe-weld | 0.5-6mm |

| Ukunikezwa kwamandla kagesi | 220V/50Hz/30A |

| Izindlela zokupholisa | Amanzi abandayo angaphakathi |

| Usayizi womshini | 456*887*718 mm |

| Isisindo sengqikithi | 180KG |

Isibuyekezo Sesistimu Entsha

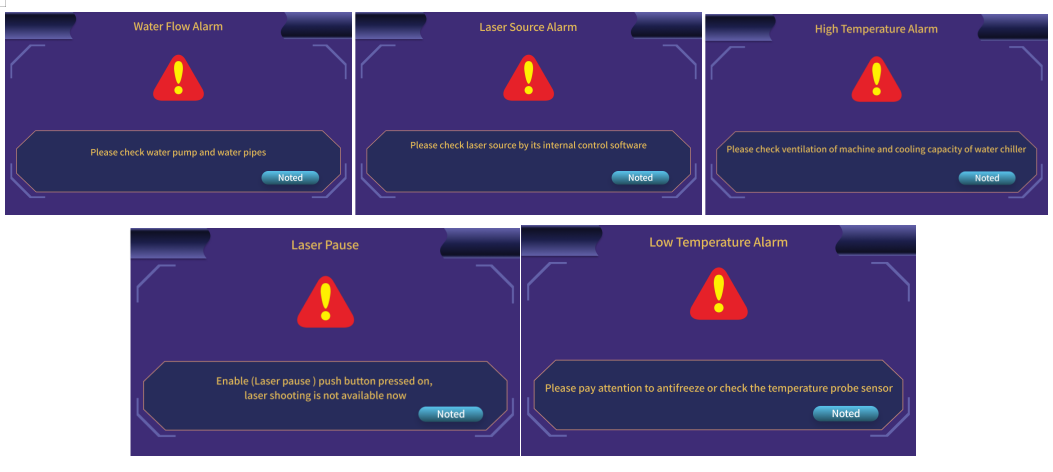

I-alamu yokugeleza kwamanzi, i-alamu yomthombo we-Laser, i-alamu ye-High Temperature, i-Laser Pause, i-alamu yezinga lokushisa eliphansi, noma iyiphi inkinga ye-laser izokubona ohlelweni, kuzoba lula kuwe ukuthi uthole inkinga ngokuqondile.

- isimo somthombo siwusizo kakhulu ekuphepheni kwakho, uma usebenzisa umshini, uma ungafinyeleli ukuphepha kwesiqeshana somhlaba, uhlelo luyoba inkomba ebomvu yokuvimbela izingozi zokuphepha emsebenzini.

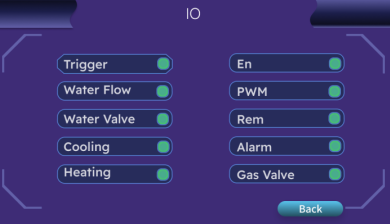

- Uhlelo olusha lwe-IO, ukuqapha okuphelele kwesimo somshini, lapho umshini wakho ukuthi iyiphi ingxenye yenkinga, uzokhanyisa ukukhanya okubomvu, ukuze ukwazi ukubona inkinga ngokushesha, kodwa futhi uyisivikelo esinamandla emva kokuthengisa.

- Amaqembu angu-8 omsebenzi wamapharamitha wesitoreji, umsebenzi omkhulu wenkumbulo, gcina imingcele yakho, uma udinga ukuhlanganisa i-workpiece yakho, lo msebenzi ungakuvumela ukuthi uqale kabusha umshini lapho ungena ngokushesha esimweni sokusebenza.

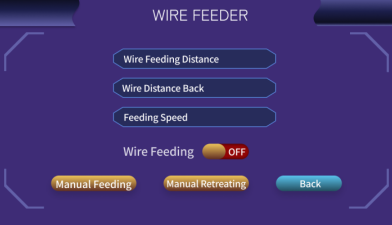

Isistimu ilawula ngokuqondile isiphakeli socingo ngaphandle kocingo, esikahle futhi siyashesha, isiphakeli socingo asinalo olunye uxhumano lwesistimu, ukhiye owodwa ophuma ocingweni, ungalawula kokubili ukuphuma nangaphakathi.

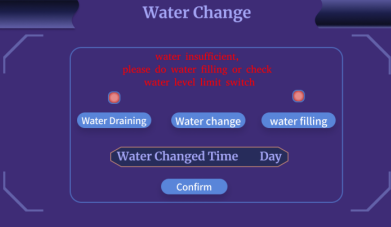

Uhlelo lulawula ngokuqondile amanzi, uhlelo lokulawula amanzi kanye nesistimu yokulawula edidiyelwe yekhabhinethi, ngoba uhlelo lwamanzi alusekho ukulawula okuhlukile, amathiphu wesikhathi, lapho izinkinga zesistimu yakho yokulawula amanzi, ungaba ngowokuqala ukwazi

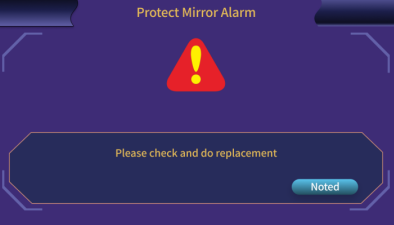

Buyekeza umsebenzi welensi yokuvikela, lapho usebenzisa umshini, lapho ilensi yokuvikela ilimele, izokwenza izingxenye zangaphakathi zomshini zibe lula ukulimaza, i-alamu yethu entsha yokusebenza kwelensi yokuvikela izonciphisa kakhulu izindleko zakho zangemuva kokuthengisa.

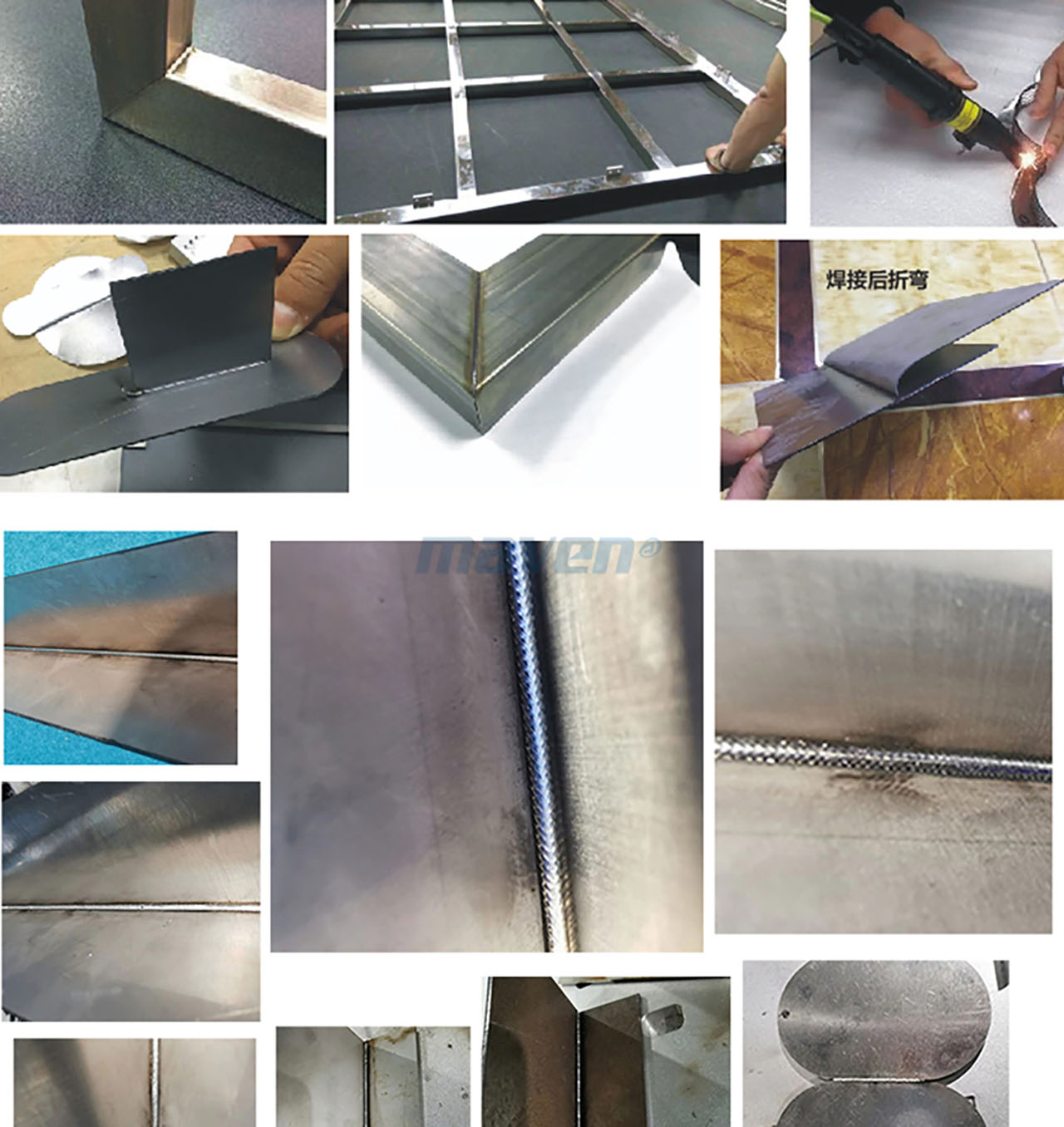

Izicelo zomshini wokushisela we-laser ophathwa ngesandla

Ikakhulukazi okwensimbi yeshidi elikhulu neliphakathi nendawo, amakhabethe, i-chassis, i-aluminium alloy iminyango kanye nohlaka lwamafasitela, isitsha sokugeza insimbi engagqwali kanye nezinye indawo enkulu yokusebenza egxilile njenge-engeli yangaphakathi yesokudla, i-angle yangaphandle yesokudla, i-welding welding seam welding, ukushisa kwe-welding indawo ethintekile encane, i-deformation encane, nokujula kwe-welding, i-welding eqinile. Isetshenziswa kakhulu embonini yasekhishini, imboni yezinto zikagesi zasendlini, imboni yokukhangisa, imboni yesikhunta, imboni yemikhiqizo yensimbi engagqwali, imboni yobunjiniyela bensimbi engagqwali, imboni yeminyango namafasitela, imboni yezobuciko, imboni yefenisha yasekhaya, imboni yefenisha, imboni yezingxenye zezimoto, njll.