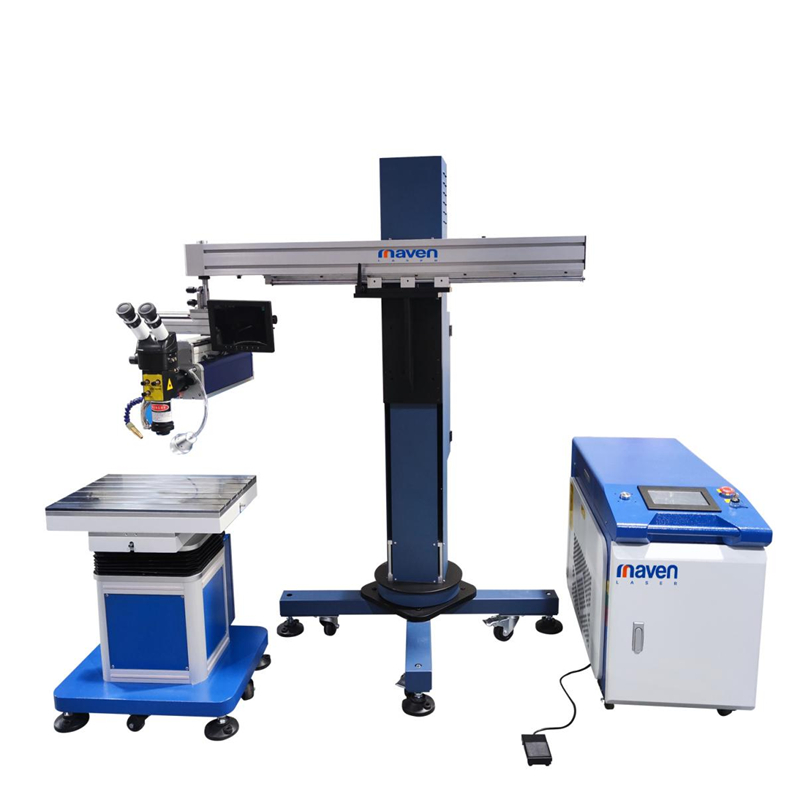

Precision Mold Repair Mold Laser Welding Machine

| Into | Igama lepharamitha | Idatha |

| Ipharamitha yomthombo we-Laser | AMANDLA OKUPHUMA AMANINGI | 1000W/1500W/2000W |

| AMANDLA EWONKE | 4KW | |

| LASER WAVELENGTH | 1080nm | |

| AMANDLA E-LASER PULSE AMANINGI | 70J/50ms | |

| UBUNZI BOMPHUPHO | 1-50ms | |

| I-PULSE FREQUENCY | 1-100HZ | |

| Umsebenzi Welding | UKULUNGISWA KWE-SPOT | 0.1-3.0mm |

| USIZI WAMASHA | 0.2mm-3mm | |

| USIZE WE-LENSE | F150mm | |

| UBUDILI BOKUSHISA | 0.1-1.2mm | |

| INDAWO YOKUGXILA | Isibonakhulu (i-CCD nayo ingangezwa) | |

| Isistimu yokulawula | UMTHOMBO WE-LASER PHEZULU SONDELA UBUDE | 300mm |

| UMTHOMBO WOKUHAMBA ISIQONDISO | I-360D Degree | |

| I-LASER HORIZONTAL DIRECTION | Y ukuhamba kwe-eksisi | |

| 3D WORKBENCH | I-XY manual, Z enenjini | |

| Izakhiwo Zomzimba Kanye Nokunye | AMANZI AMAPHOLISA AMANDLA | 1.2P |

| AMANDLA VOLTAGE | 220V±10% 50Hz 30A | |

| INDAWO YOKUSEBENZA | Hlanza akukho ukugqwala, 13℃-28℃ | |

| OKUDLIWAYO | Isibuko esivikelekile |

Izinzuzo Zomkhiqizo

Isimiso se-mold laser welding machine.

Umshini wokushisela usetshenziswa kakhulu ukugcwalisa izimbobo kanye ne-trachoma ye-welding yegolide nobucwebe besiliva. Insimbi engagqwali ye-laser spot welder iyisici esibalulekile se-laser spot welder ekusetshenzisweni kobuchwepheshe bokucubungula impahla ye-laser.

Esinye sezici ezibalulekile, inqubo yokushisela indawo ye-laser uhlobo lwe-heat conduction, okungukuthi, ukushisa ngemisebe ye-laser ebusweni bomsebenzi, ukushisa okungaphezulu ngokuqhutshwa kokushisa kuya ekusakazeni kwangaphakathi,

Inqubo yokushisela indawo ye-laser iwuhlobo lwe-heat conduction, lapho imisebe ye-laser ishisa ingaphezulu le-workpiece kanye nokushisa okungaphezulu kuhlakazeka ngaphakathi ngokuqhutshwa kokushisa. Ngenxa yezinzuzo zayo eziyingqayizivele

Isetshenziswe ngempumelelo ekucubunguleni ubucwebe begolide nesiliva kanye nokushisela izingxenye ezincane nezincane.

Izici zomshini wokushisela we-Mold laser.

◆ Yamukela imbobo yokubona i-ceramic evela kwamanye amazwe, ukumelana nokugqwala, ukumelana nezinga lokushisa eliphezulu, ukuphila komgodi (8-10) iminyaka, ukuphila kwesibani se-xenon izikhathi ezingaphezu kwezigidi ezingu-8.

◆Adopt automatic shading system, esusa ukugqugquzelwa kwamehlo ngesikhathi samahora okusebenza.

◆10X ukukhulisa isibonakhulu, inkomba yekhesa ephambanayo, nokufiphaza okuzenzakalelayo ngevalvu yokukhanya ye-LCD enesivinini esikhulu. Igesi evikelayo ephumayo evunyelaniswe ne-laser iqinisekisa ukuthi i-solder ehlangene yinhle futhi i-solder joint ngeke i-oxidized futhi ishintshe umbala.

◆Isibonisi samukela isikrini se-LED esingu-7 intshi, esingabona ukushintsha kwamahhala phakathi kwesiShayina nesiNgisi, futhi sihambisana nemakethe yamazwe ngamazwe.

Umshini wokushisela isikhunta se-laser usetshenziswa kabanzi ekubumbeni, ekubumbeni umjovo ngokunemba, ukuphonsa ukufa, ukunyathela, insimbi engagqwali nezinye izinto eziqinile ezifana nokuqhekeka, ukuchotshozwa, ukugaya nokugqoka ukulungisa unqenqema lokuvala, ukushisela, amabhethri omakhalekhukhwini, ubucwebe, izingxenye ze-elekthronikhi, izinzwa, imishini enembayo, ezokuxhumana, amaketela, amabhodwe ewayini, amabhodwe ekhofi, imisebenzi yezandla nezinye izimboni.

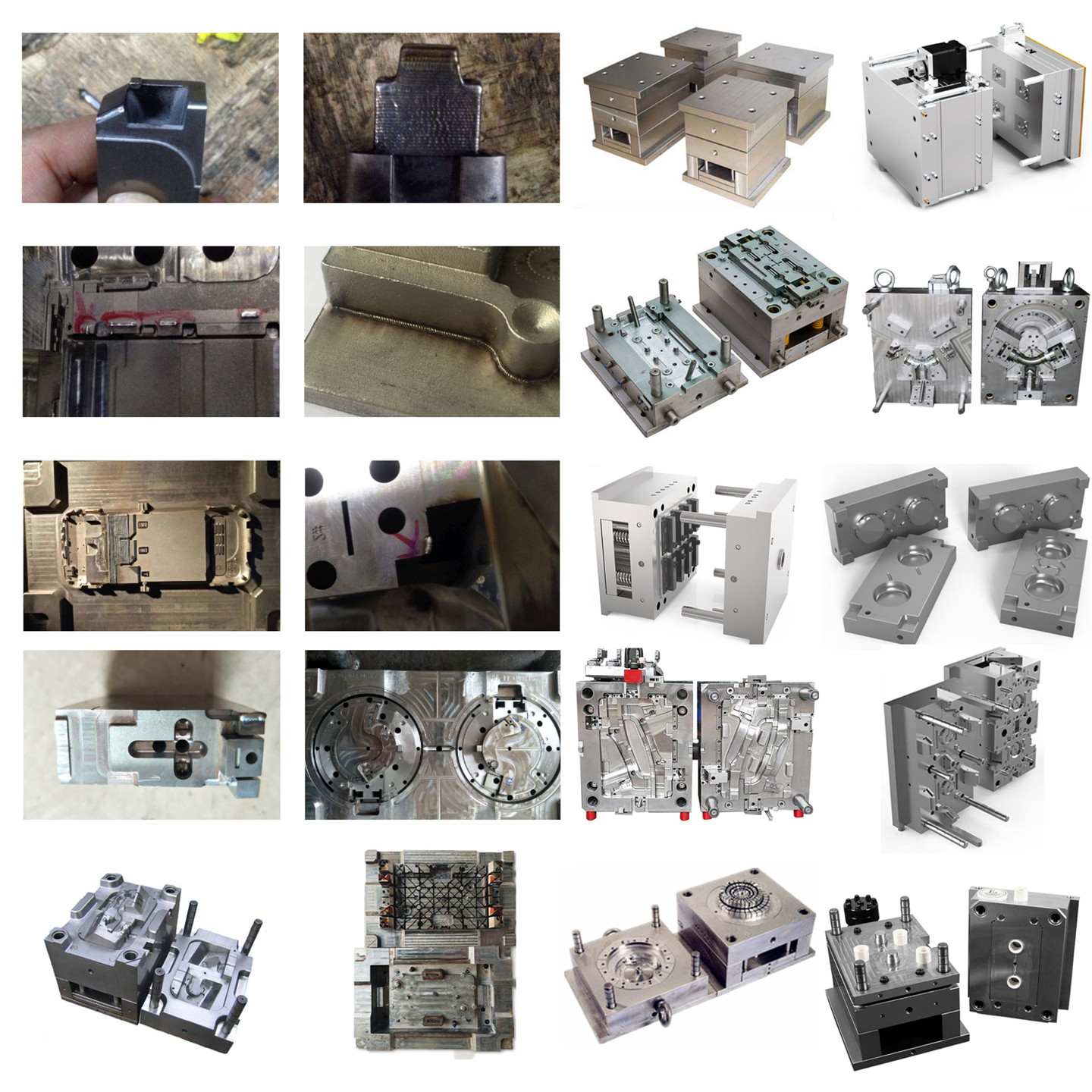

Isampula nohlelo lokusebenza