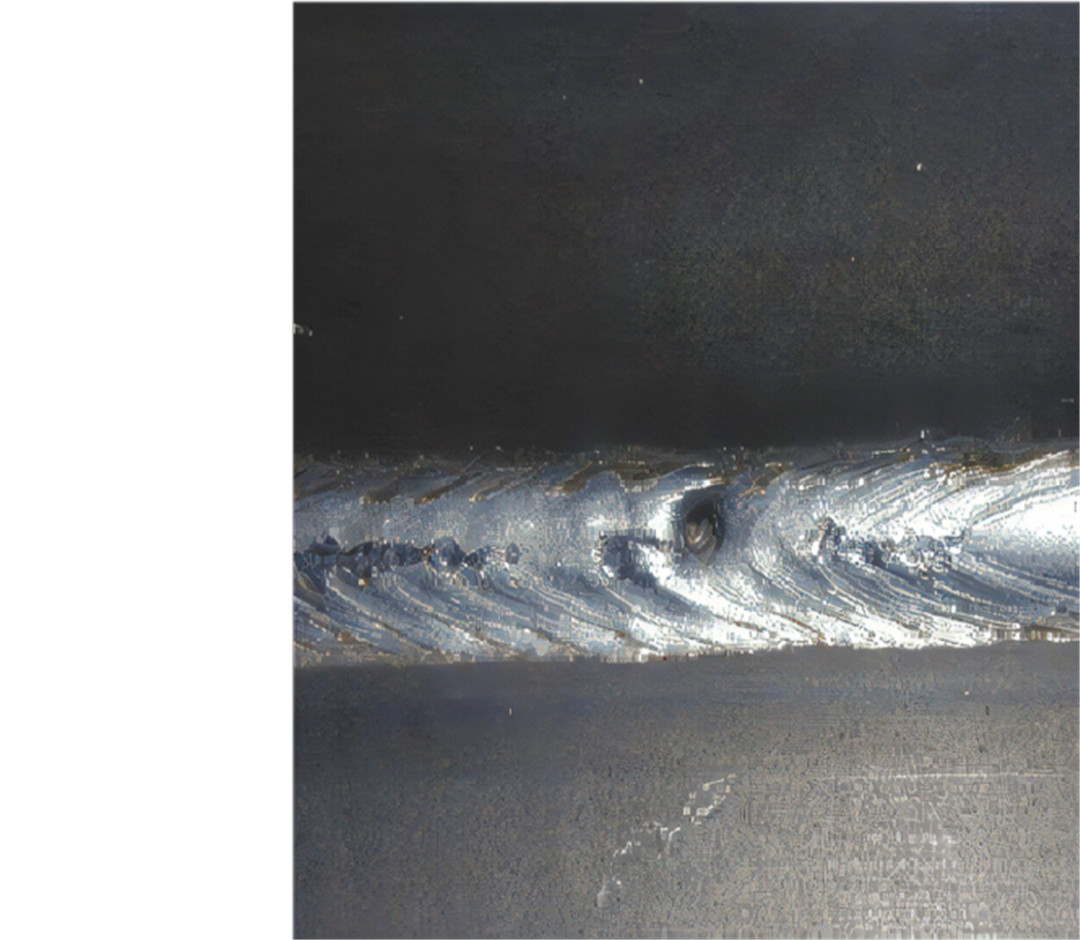

1. Inkinga: I-slag splash

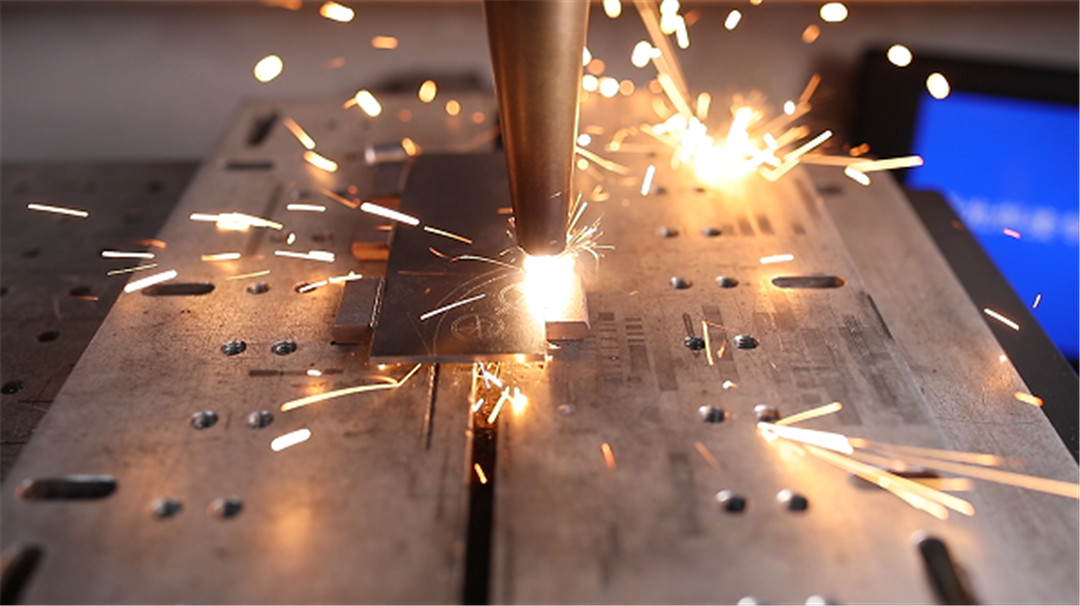

Enqubweni ye-laser welding, izinto ezincibilikile zisakazeka yonke indawo futhi zinamathele ebusweni bezinto, okwenza izinhlayiya zensimbi zivele phezulu futhi zithinte ubuhle bomkhiqizo.

Isizathu senkinga: i-spatter ingase ibe ngenxa yamandla amaningi okuholela ekuncibilikeni okusheshayo, kodwa futhi ngenxa yokuthi indawo ebonakalayo ayihlanzekile, noma igesi inamandla kakhulu.

Isixazululo: 1, ukulungiswa kwamandla okufanelekile; 2, naka impahla yokuhlanza ebusweni; 3, ukunciphisa ingcindezi igesi.

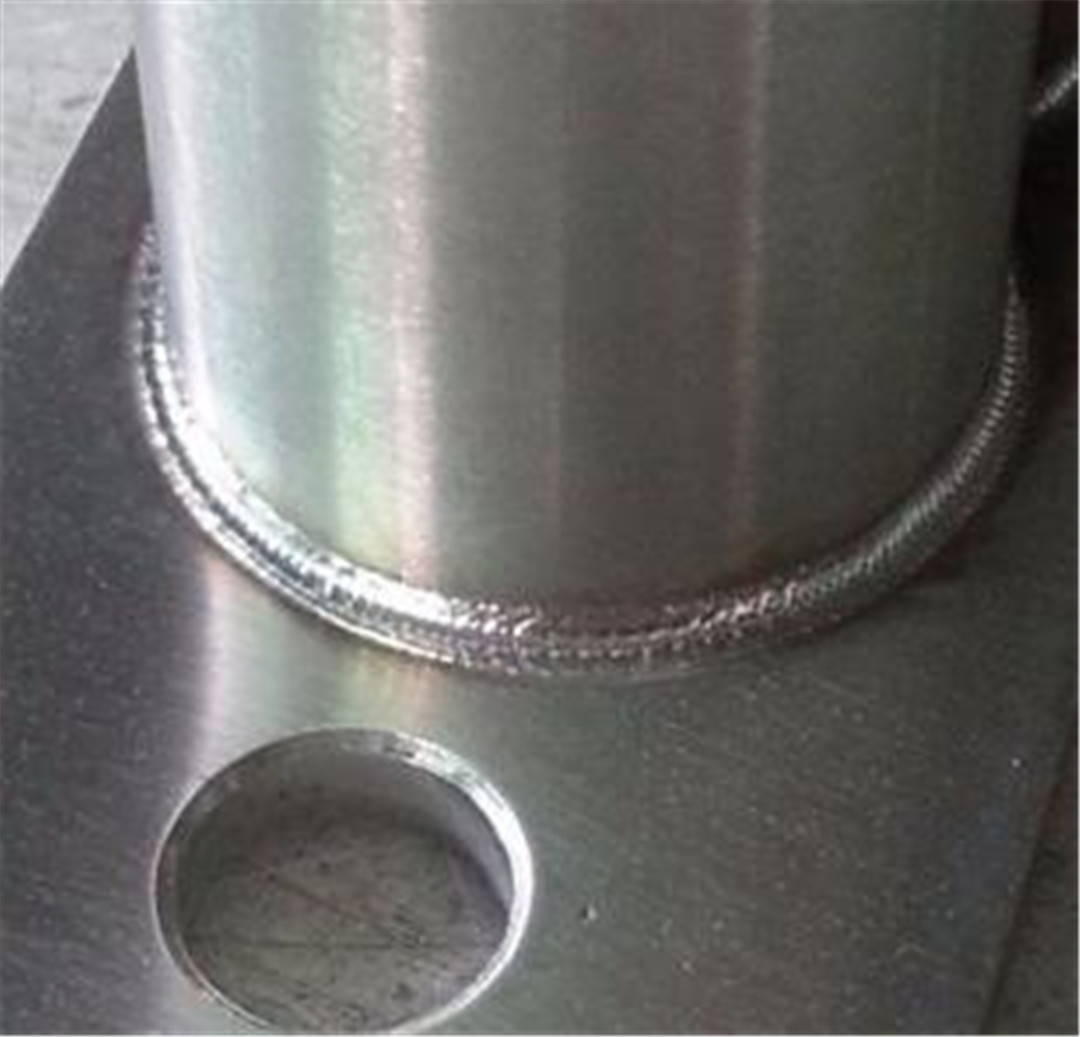

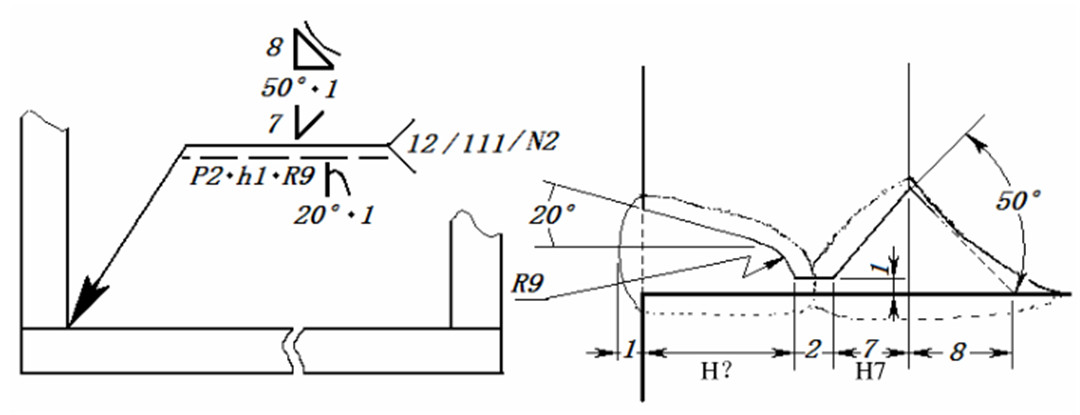

2. Inkinga: I-weld seam iphezulu kakhulu

I-Welding izothola ukuthi i-weld seam iphakeme kakhulu kunezinga elivamile, okuholela ekuthungeni okunamafutha, okubukeka kungathandeki kakhulu.

Isizathu senkinga: isivinini sokuphakela kwentambo sishesha kakhulu, noma isivinini sokushisela sihamba kancane.

Isixazululo: 1. Yehlisa isivinini sokuphakela ngocingo ohlelweni lokulawula; 2. Khulisa isivinini sokushisela.

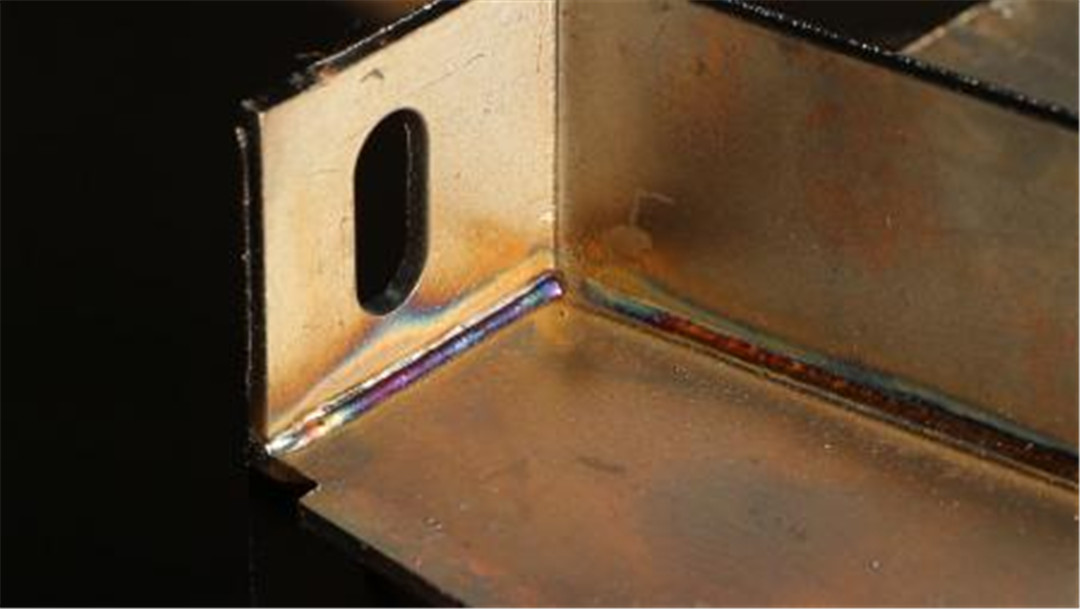

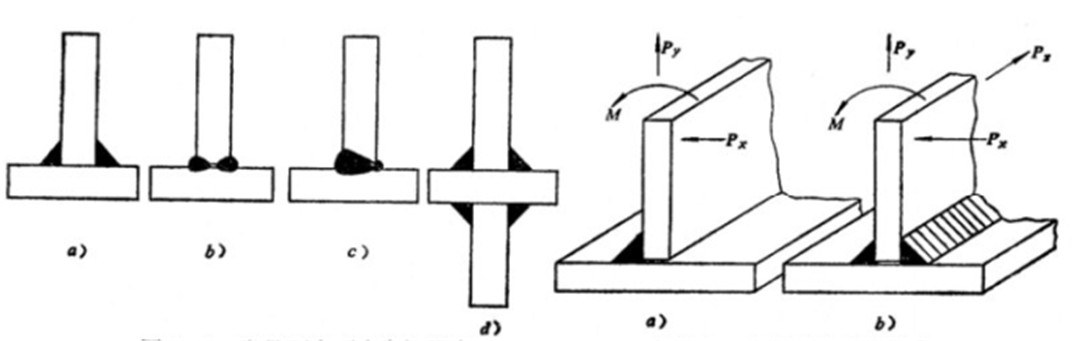

3. Inkinga: I-Welding offset

I-Welding ngaphandle kokuqina emajoyini esakhiwo kanye nokuma okungalungile kungaholela ekuhlulekeni okuphelele kokushisela.

Isizathu senkinga: ukuma okungalungile ngesikhathi sokushisela; ukuma okungahambisani kokuphakelayo kocingo kanye ne-laser irradiation.

Isixazululo: 1. Lungisa i-laser offset kanye ne-swing angle ebhodini; 2. Hlola ukuxhumana phakathi kwesiphakeli socingo nekhanda le-laser ukuze kuphambuke.

4. Inkinga: Umbala we-weld umnyama kakhulu

Lapho ushisela insimbi engagqwali, ingxubevange ye-aluminium nezinye izinto, umbala we-weld umnyama kakhulu uzokwenza i-weld kanye nendawo ebonakalayo ikhiqize umehluko oqinile, ithinte kakhulu ubuhle.

Isizathu senkinga: amandla e-laser mancane kakhulu okuholela ekushiseni okunganele, noma isivinini sokushisela sishesha kakhulu.

Isixazululo: 1. lungisa amandla laser; 2. lungisa isivinini sokushisela.

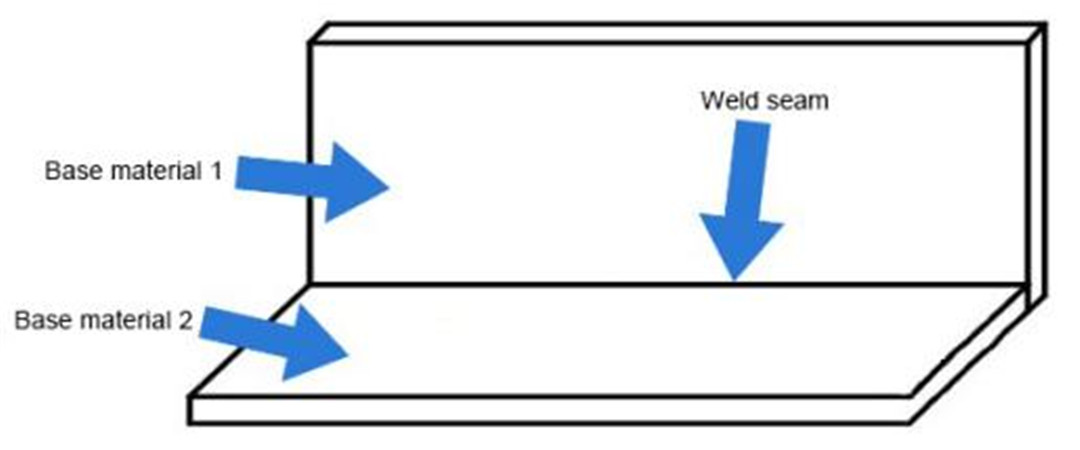

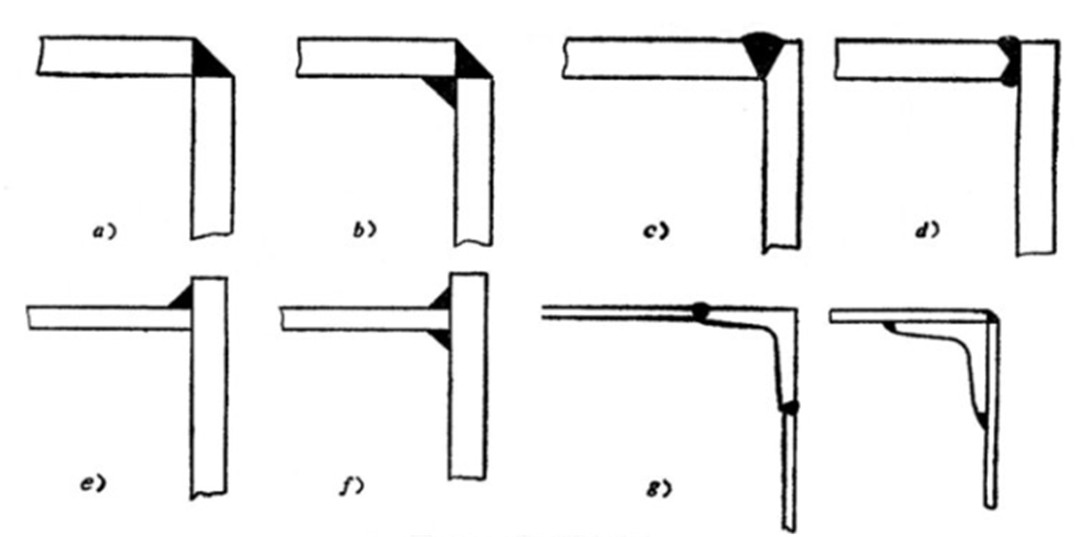

5. Inkinga: Ukulinganisa ukubunjwa kwe-welding ekhoneni

Lapho ushisela amakhona angaphakathi nangaphandle, amakhona awalungiswanga ngesivinini noma ukuma, okungaholela kalula ekushiseni okungalingani emakhoneni, okuthinta kokubili amandla e-weld nobuhle be-weld.

Imbangela yenkinga: ukuma kwe-welding okungalungile.

Isixazululo: Lungisa i-focus offset ohlelweni lokulawula i-laser ukuze ikhanda le-laser eliphathwayo likwazi ukwenza imisebenzi yokushisela eceleni.

6. Inkinga: ukucindezeleka kwe-welding seam

Amadents ekuhlanganyeleni okushiselwe azoholela emandleni okushisela anganele kanye nemikhiqizo engafanelekile.

Imbangela yenkinga: Amandla e-laser makhulu kakhulu, noma i-laser focus isethwe ngendlela engalungile, okubangela ukuthi i-melt pool ijule kakhulu futhi okokusebenza kuncibilike ngokweqile, okuholela ekucindezelekeni komthungo we-weld.

Isixazululo: 1. Lungisa amandla e-laser; 2. Lungisa ukugxila kwe-laser.

7. Inkinga: ubukhulu be-weld abufani

Umthungo we-Weld ngezinye izikhathi mkhulu kakhulu, ngezinye izikhathi ube mncane kakhulu, noma ngezinye izikhathi ujwayelekile.

Imbangela yenkinga: ukukhanya noma intambo yokuphakelayo akuyona inkinga.

Isixazululo: Hlola ukuqina kwe-laser kanye ne-wire feeder, okuhlanganisa amandla kagesi kagesi, isistimu yokupholisa, isistimu yokulawula, izintambo eziphansi, njll.

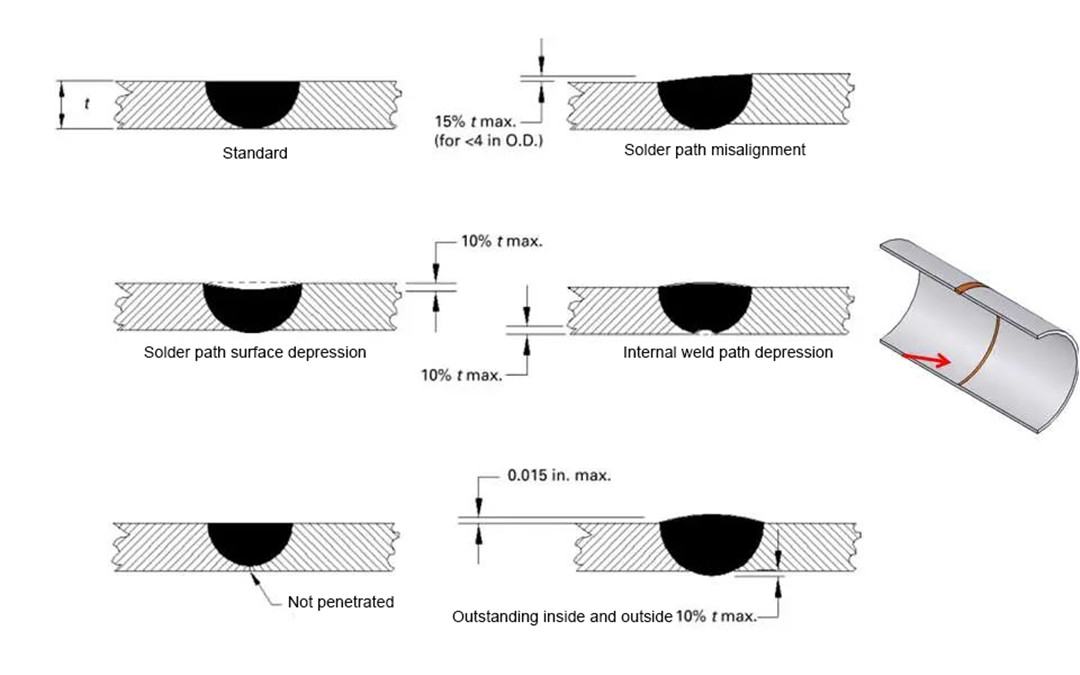

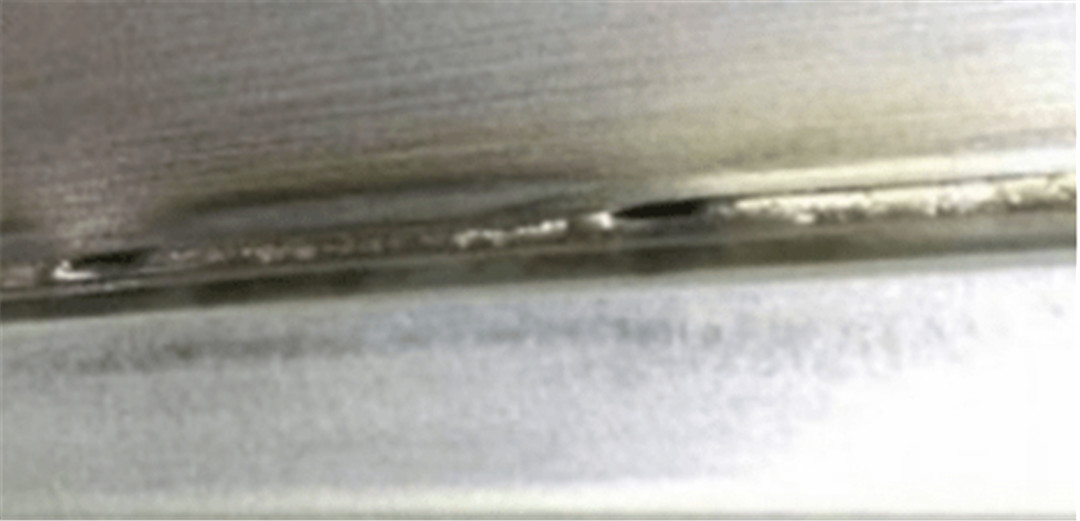

8. Inkinga: Unqenqema lokuluma

I-bite edge ibhekisela ku-weld futhi impahla ayihlanganisiwe kahle, i-beveling nezinye izimo, ngaleyo ndlela ithinta izinga lokushisela.

Isizathu senkinga: isivinini se-welding sishesha kakhulu, okuholela echibini lokuncibilika lingasatshalaliswa ngokulinganayo ezinhlangothini zombili zezinto ezibonakalayo, noma igebe lempahla likhulu, impahla yokugcwalisa ayanele.

Isixazululo: 1. Lungisa amandla we-laser nesivinini ngokuya ngamandla wento kanye nobukhulu bomthungo we-weld; 2. Yenza umsebenzi wokugcwalisa noma wokulungisa kamuva.

I-Maven Laser Automation Co., Ltd. (I-Maven laser ngamafuphi) ingumkhiqizi ohamba phambili wezinhlelo ze-laser kanye nezixazululo ezizenzakalelayo ezizenzakalelayo, eziseShenzhen, eChina, eyasungulwa ngo-2008. Imikhiqizo yethu yobungcweti yilena: umshini wokuhlanza i-laser, umshini wokushisela i-laser, umshini wokushisela amarobhothi kanye nomshini wokushisela wesikhulumi, uma unemibuzo yobungcweti, wamukelekile ukuxhumana nathi.

Isikhathi sokuthumela: Nov-18-2022