Ngokuthuthuka okuqhubekayo kwesayensi nobuchwepheshe kanye nokwandiswa kwemikhakha ehlukahlukene yezicelo,laserubuchwepheshe bokucubungula bungena kancane kancane kuzo zonke izigaba zokuphila futhi buba ithuluzi elibalulekile lokucubungula. Ekusetshenzisweni kwama-laser,I-MOPA yezinga le-kilowatt(I-Master Oscillator Power-Amplifier) amalaser asetshenziswa kakhulu emikhakheni efana nokucutshungulwa kwezinto kanye nokuhlolwa kocwaningo lwesayensi ngenxa yamandla awo aphezulu aphezulu, ukungena okuqinile, nomthelela ophansi wokushisa. Ziyithuluzi elibalulekile lokusiza amabhizinisi ukuthuthukisa ikhwalithi futhi andise umkhiqizo. Ithuluzi ekahle ukusebenza kahle. Kodwa ngenxa yamandla ayo aphezulu, ukuze kwandiswe ukusebenza kahle kwelaser ye-MOPA yezinga le-kilowatt, ukukhethwa kwezisekeli kubalulekile. Ngokukhetha izesekeli ezifanele ze-laser kuphela lapho singaqinisekisa ukuthi i-laser ingasebenza ngokuzinza nangempumelelo futhi ihlangabezane kangcono nezidingo ezahlukahlukene zohlelo.

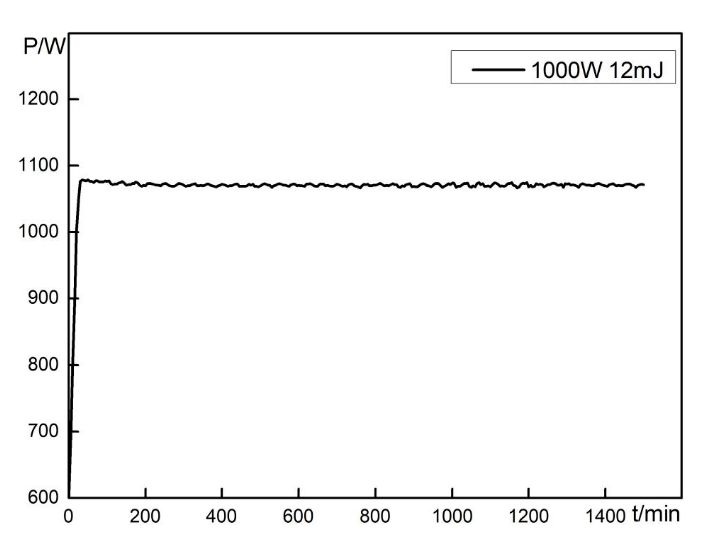

Ukuqina kwamandla aphezulu

Ukukhiqizwa okuningi kwe-kilowatt-level MOPA enokusebenza okuphezulu nezinkomba zobuchwepheshe

Ikhono lokukhiqiza ngobuningi ngokuzinzaamalaser emodi eyodwa ye-MOPA enezinga le-kilowattiyinkomba ebalulekile ye-MOPA laser R&D yenkampani, amakhono okukhiqiza nawokukhiqiza. I-MAVEN njengamanje inezinguqulo eziningi zemishini yokuhlanza i-fiber laser ye-MOPA yamandla aphezulu engahlangabezana nezidingo zokucubungula izinhlelo zokusebenza ezihlukahlukene ngezilinganiso eziningi.

Ukushintshashintsha kokuphuma kwamandla okugcwele okungu-24h kungaphansi kuka-<3%

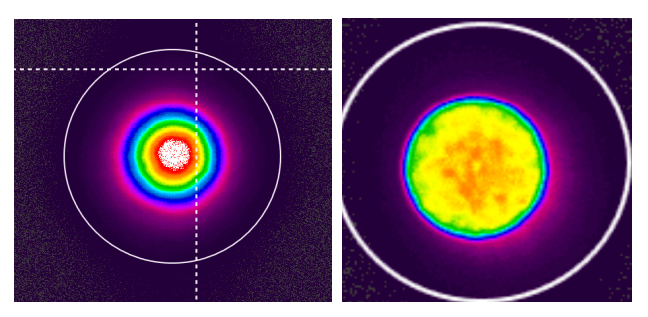

Ikhwalithi ye-Beam iyalawuleka

I-Gaussian beam yemodi eyodwa I-multi-mode flat-top beam

Ubuchwepheshe bokuhlanganisa isignali yepompo yokuphela, ukusatshalaliswa kwezinga lamandla okucwengisiswe kakhudlwana futhi okunengqondo, inqubo eyingqayizivele yokuhlanganisa ukukhiqizwa, kanye nemodi eyodwa enamandla amakhulu e-collimated isolator enekristalu ebonisa ukushisa enhle kakhulu, kuyilapho amandla okukhiphayo efinyelela ku-1000W, ingaqinisekisa futhi izinga elihle kakhulu le-Beam.

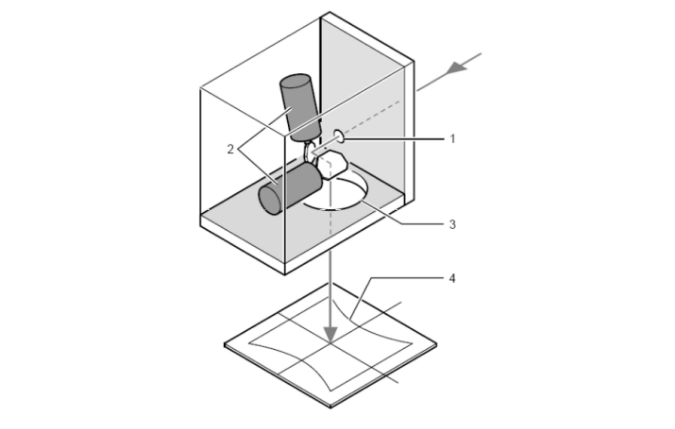

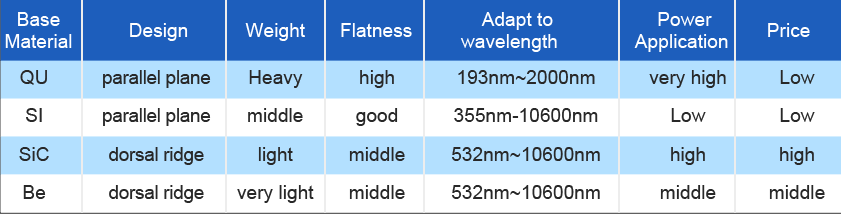

Emkhakheni we-fiber laser processing, ikakhulukazi ukucubungulaamandla aphezulu e-MOPA nanosecond pulse fiber laser, ngenxa yamandla ayo aphezulu aphezulu, amandla amakhulu e-pulse kanye nemvamisa ephezulu, ukukhethwa kwezesekeli kubaluleke kakhulu. Izesekeli eziyinhloko ezithinta umphumela wokucubungula we-high-power pulse laser zihlanganisa i-Scanning galvanometer, isibuko sensimu esigxile kanye nesibonisi.

Ungakhetha kanjani i-galvanometer yokuskena?

Umgomo wobuchwepheshe bokuskena be-galvanometer ukuqedela imisebenzi yokuskena enesivinini esikhulu, enembe kakhulu. Kunezici ezimbili eziyinhloko ezinqumayo. Enye isistimu yokulawula engafinyelela isivinini esikhulu nokunemba okuphezulu, kanti enye i-galvanometer enesivinini sokuphendula esisheshayo. isithwebuli. Isakhiwo se-galvanometer ngokuyinhloko siqukethe izingxenye ezintathu: i-reflector, imoto nekhadi lokushayela, phakathi kwayo i-lens ibalulekile ekuzinzeni kokucubungula.

I-Galvanometer lens impahla kanye nezinkomba ezithonyayo

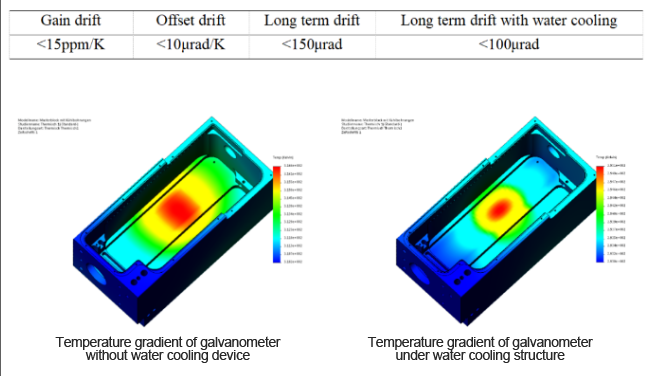

Uhlelo lokuphatha olushisayo lweukuskena i-galvanometerfuthi kuyisici esibalulekile ekuqinisekiseni ukuzinza kokucubungula isikhathi eside. Ukwehluka kwezinga lokushisa kuzobangela ukuthi i-galvanometer ikhukhuleke futhi yehlise ukunemba kokuma. Amanani ajwayelekile ami kanje. Ngokuchitha ukushisa okusebenzayo okupholisa amanzi, ukuzinza kokucubungula isikhathi eside kungathuthukiswa ngo-30%.

Inani elijwayelekile lokukhukhuleka kwezinga lokushisa le-galvanometer

Idivayisi yokupholisa amanzi ingakwazi ukususa ukushisa ngokuphumelelayo futhi iqinisekise ukusebenza okuzinzile kwesikhathi eside kwe-galvanometer. Izindlela zobuchwepheshe eziyinhloko ziwukuthola insimu yamanzi okupholisa isiyaluyalu esiphansi ngomklamo olungiselelwe womzila wamanzi okupholisa, kanye nokuklama isakhiwo esisebenza kahle sangaphandle sedivayisi yokushintshisana ukushisa.

Kusistimu ye-laser ye-MOPA yezinga eliphezulu ye-kilowatt, sincoma ngokuqinile ukusetshenziswa kwamalensi equartz ekhwalithi ephezulu namasistimu e-galvanometer anezinhlelo zokupholisa amanzi.

Indlela yokukhetha i-lens yensimu yokugxila?

Ilensi yasendle igxilisa ugongolo lwe-laser ehlanganisiwe endaweni ethile, ikhuphule ukuminyana kwamandla we-laser beam, futhi isebenzisa amandla aphezulu e-laser ukwenza ukucubungula kwezinto ezihlukahlukene njengokusika, ukumaka, ukushisela, ukuhlanza kanye nokwelashwa kwendawo.

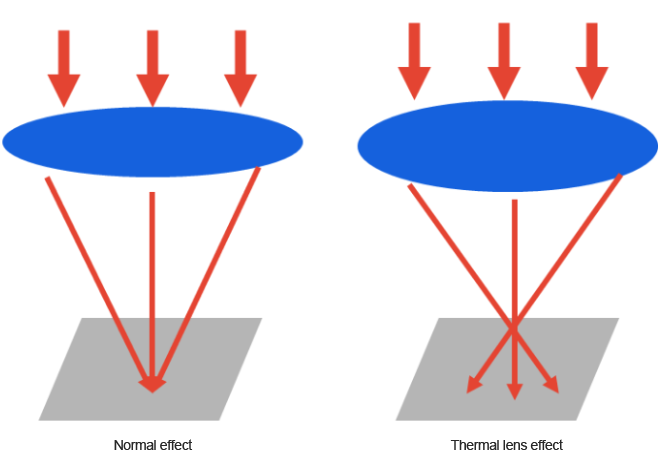

Izici eziyinhloko ezithinta ikhwalithi yokucubungula kanye nomthelela welensi yasensimini yizinto ezibonakalayo zelensi yasendle kanye nokuphakama kweringi ye-adaptha. Izinto eziyinhloko ze-lens yasendle yingilazi ne-quartz. Umehluko phakathi kwalokhu okubili usemthelela welensi eshisayo emandleni aphezulu. Ngemuva kokuthi i-lens yensimu yokugxila ihlale i-radiated yi-laser beam isikhathi eside, izokhiqiza ukuguqulwa okushisayo ngenxa yokwanda kwezinga lokushisa, okuzobangela ukudluliswa kwe-optics. Inkomba ye-refractive ye-elementi kanye nesiqondisindlela sokubonisa soshintsho lwento ekhanyayo ekhanyayo, kanye nomthelela welensi eshisayo izothinta imodi ye-laser kanye nendawo yokugxila ngemuva kokugxila, okuzothinta kakhulu umphumela wokucubungula. I-Quartz ine-coefficient ephansi yokwandisa okushisayo kanye nokudluliswa okuphezulu, okuyenza ibe ukukhetha okungcono kakhulu kwamalensi enkundla yamandla aphezulu. Uma kunesidingo, imojula yokupholisa amanzi kufanele yengezwe.

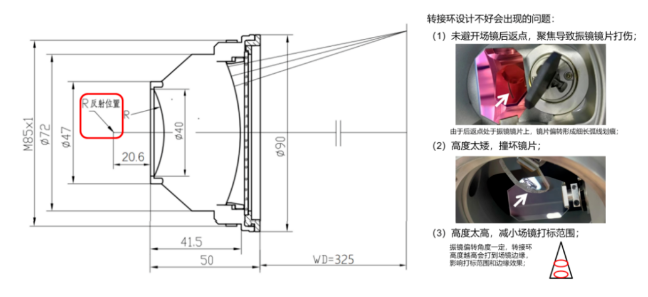

I-adaptha iringi yokufanisa ilensi yasensimini ne-galvanometer nayo iyisici esibalulekile esithinta okokusebenza nokucubungula. Ubude obufanele bendandatho ye-adaptha bungagwema indawo yokubuyisela ilensi yensimu futhi kuqinisekise ifomethi yokucubungula. Uma iphezulu kakhulu noma iphansi kakhulu, izodala izinkinga ezihambisanayo.

Kumasistimu welaser ye-MOPA yezinga eliphezulu yamandla e-kilowatt, sincoma ngokuqinile ukusetshenziswa kwezibuko zekhwalithi ephezulu zequartz ezinamamojula okupholisa amanzi kanye neringi ye-adaptha yesibuko yasensimini ezinikele yobude obufanele.

Indlela yokufanisa amalensi akhanyayo?

Umsebenzi oyinhloko wamalensi akhanyayo esakhiweni sendlela ye-optical ukushintsha isiqondiso sendlela yokubona. Ukukhetha amalensi akhanyayo ekhwalithi enhle nezindlela zokufaka ezijwayelekile zingadlala indima enkulu kwezinye izinhlelo zokusebenza ezikhethekile, kodwa amalensi ekhwalithi ephansi nezindlela zokuwafaka ezingenangqondo nazo zizodala umbuzo Omusha. Izici ezibonakalayo zelensi zinqunywa ubude beza kanye namandla e-laser. I-substrate ngokuvamile yenziwe nge-quartz ehlanganisiwe noma i-crystalline silicon. Ifilimu ekhanyayo ye-laser ngokuvamile yenziwa ngefilimu esiliva noma ifilimu ye-dielectric ebonakalayo, enokubukeka okuphezulu, izinga lokumunca eliphansi kanye nokumelana ne-laser. Izici zomkhawulo womonakalo omkhulu.

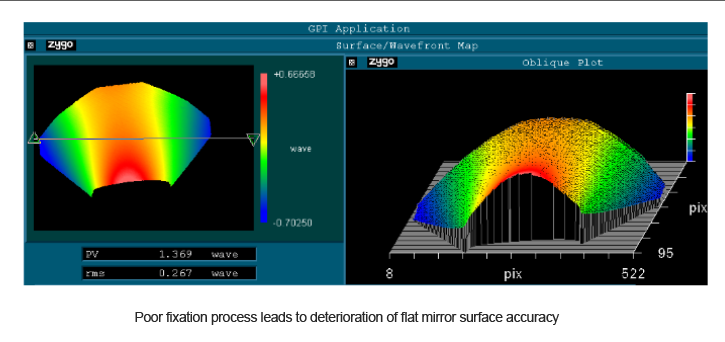

Isibonisi sendiza esifanelekile ngeke sithinte ikhwalithi yokugxila, kodwa ekusetshenzisweni kwangempela, indiza ebonisayo ingase yonakale ngenxa yezinto ezicindezelayo ezifana nokulungiswa kwezikulufu, okufana nesibuko esiyisilinda. Ukuhlanekezela kuthinta kakhulu ikhwalithi yendawo okugxilwe kuyo, kubangele i-astigmatism ye-oda eliphansi kanye nezinye i-astigmatism yezinga eliphansi. I-Aberration ivimbela indawo okugxilwe kuyo ukuthi ifinyelele umkhawulo wokuphazamiseka, okuthinta ikhwalithi yokucubungula nomthelela.

Kumasistimu e-MOPA pulse laser esezingeni eliphakeme ye-kilowatt, sincoma ngokuqinile ukusetshenziswa kwezibonisi zequartz zekhwalithi ephezulu kanye nezindlela zokufaka ezifanele ukuze kuqinisekiswe ukuthi amalensi anamandla ngaphandle kokuguquguquka.

Isikhathi sokuthumela: Sep-13-2023