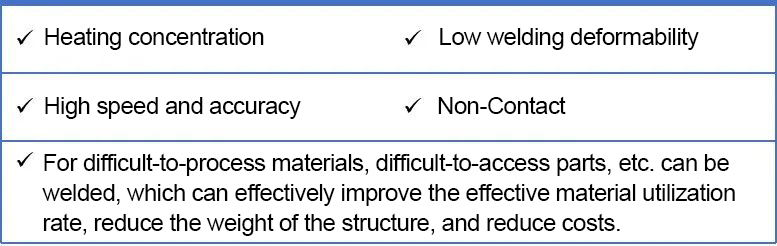

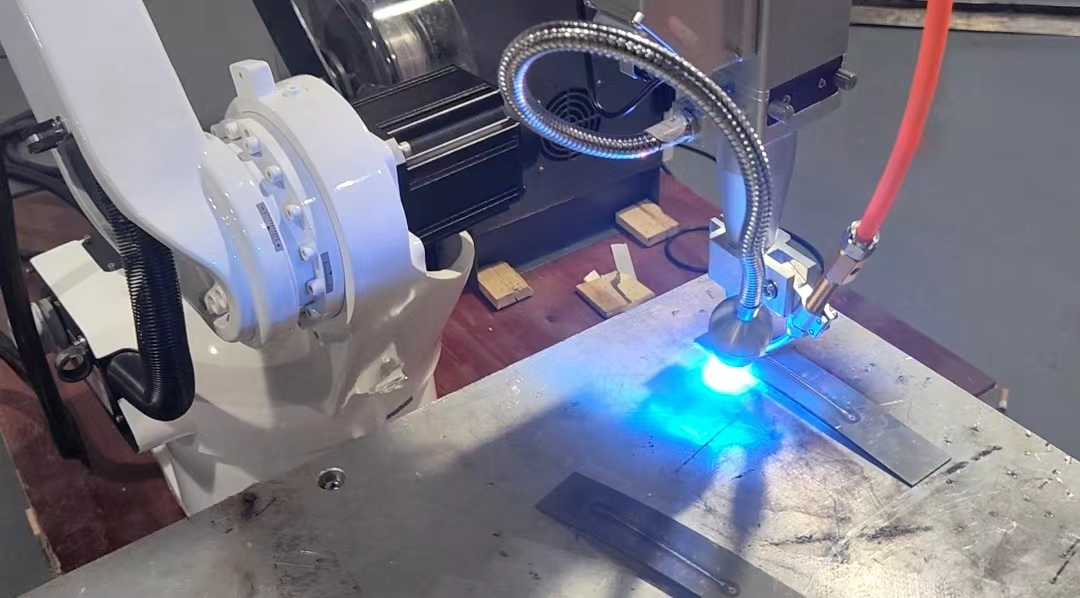

Ubuchwepheshe bokujoyina i-laser, noma ubuchwepheshe be-laser welding, busebenzisa i-laser beam enamandla amakhulu ukuze kugxilwe futhi kulawule ukushiswa kwempahla, futhi indawo ebonakalayo imunca amandla e-laser futhi iwaguqule abe amandla okushisa, okubangele ukuthi okokusebenza kushise futhi kuncibilike. , okulandelwa ukupholisa nokuqiniswa ukuze kufinyelelwe ukuhlanganiswa kwezinto ezifanayo noma ezingafani. Inqubo ye-laser welding idinga ukuminyana kwamandla we-laser okungu-104kuye 108W/cm2. Uma kuqhathaniswa nezindlela zokushisela zendabuko, i-laser welding inezinzuzo ezilandelayo.

Ubuchwepheshe bokujoyina i-laser, noma ubuchwepheshe be-laser welding, busebenzisa i-laser beam enamandla amakhulu ukuze kugxilwe futhi kulawule ukushiswa kwempahla, futhi indawo ebonakalayo imunca amandla e-laser futhi iwaguqule abe amandla okushisa, okubangele ukuthi okokusebenza kushise futhi kuncibilike. , okulandelwa ukupholisa nokuqiniswa ukuze kufinyelelwe ukuhlanganiswa kwezinto ezifanayo noma ezingafani. Inqubo ye-laser welding idinga ukuminyana kwamandla we-laser okungu-104kuye 108W/cm2. Uma kuqhathaniswa nezindlela zokushisela zendabuko, i-laser welding inezinzuzo ezilandelayo.

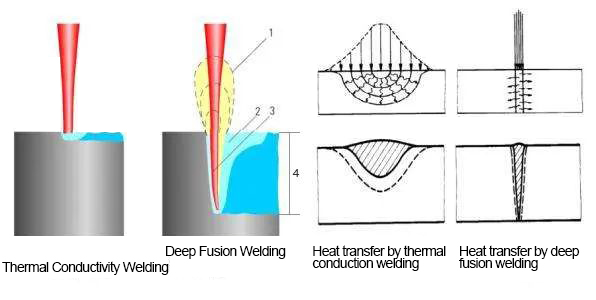

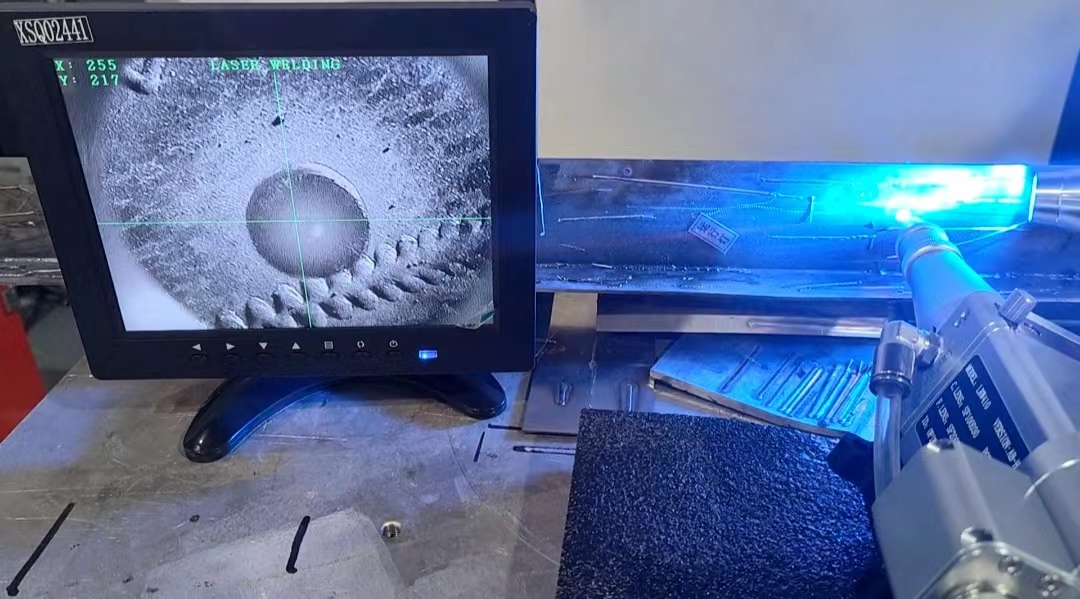

Ifu le-plasma elingu-1, impahla encibilikayo engu-2, imbobo yokhiye engu-3, ukujula okungu-4 kokuhlanganisa

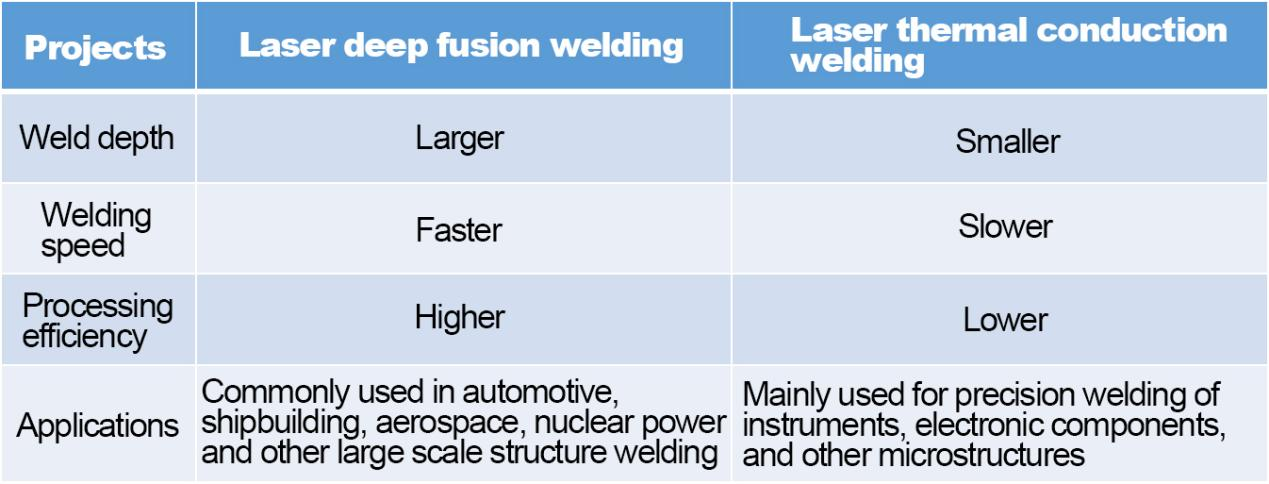

Ngenxa yokuba khona kwembobo kakhiye, i-laser beam, ngemuva kokukhanyisa ngaphakathi kwembobo kakhiye, izokwandisa ukumuncwa kwe-laser ngezinto futhi ikhuthaze ukwakheka kwechibi elincibilikisiwe ngemuva kokuhlakazeka neminye imiphumela, izindlela ezimbili zokushisela ziyaqhathaniswa. Ngokulandelayo.

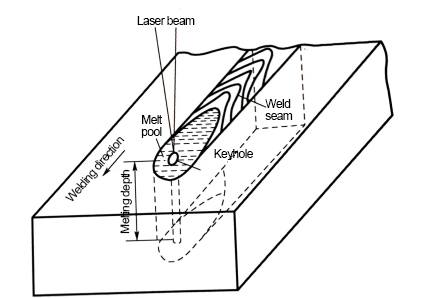

Lesi sibalo esingenhla sinikeza inqubo yokushisela nge-laser yezinto ezifanayo kanye nomthombo wokukhanya ofanayo, indlela yokuguqula amandla yenziwa kuphela ngembobo kakhiye, imbobo kakhiye kanye nensimbi encibilikisiwe eduze kodonga lwembobo ihamba nokuhamba phambili kwe-laser beam, insimbi encibilikisiwe isusa imbobo kakhiye emoyeni oshiywe ngemuva ukuze igcwale futhi ngemva kokujiya, yenze i-weld seam.

Uma impahla ezoshiselwa iyinsimbi engafani, ukuba khona komehluko ezindaweni ezishisayo kuzoba nomthelela omkhulu enqubweni yokushisela, njengokwehluka kwamaphuzu ancibilikayo, ukuqhutshwa kwe-thermal, umthamo wokushisa othize, kanye nama-coefficients wokunweba wezinto ezahlukahlukene, okuholela ekucindezelweni kwe-welding, i-welding deformation, kanye nezinguquko ezimweni ze-crystallization zensimbi ehlangene ehlanganisiwe, okubangela ukwehla kwezakhiwo zemishini ye-weld.

Ngakho-ke, ngokwezici ezahlukahlukene zesigcawu sokushisela, inqubo yokushisela ithuthukise i-laser filler welding, i-laser brazing, i-dual-beam laser welding, i-laser composite welding, njll.

I-Laser Wire Filling Welding

Enqubweni yokushisela nge-laser ye-aluminium, i-titanium ne-alloys yethusi, ngenxa yokumuncwa okuphansi kokukhanya kwe-laser (<10%) kulezi zinto, i-plasma ekhiqizwe isithombe inokuvikela okuthile kokukhanya kwe-laser, ngakho-ke kulula ukwenza i-spatter futhi kuholela ekwakhekeni kweziphambeko ezinjengokuqina nokuqhekeka. Ngaphezu kwalokho, ikhwalithi yokushisela nayo iyathinteka lapho igebe phakathi kwezinto zokusebenza likhulu kunobubanzi bebala ngesikhathi sokufafaza kwepuleti elincane.

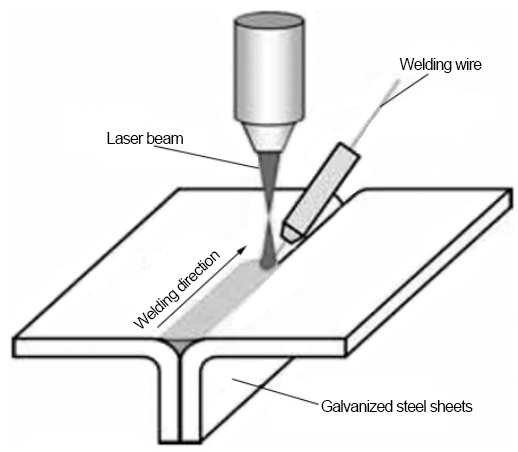

Ekuxazululeni izinkinga ezingenhla, umphumela we-welding ongcono ungatholakala ngokusebenzisa indlela yezinto zokugcwalisa. I-filler ingaba ngocingo noma impushana, noma indlela yokugcwalisa esethiwe ingasetshenziswa. Ngenxa yendawo encane egxilile, i-weld iba mncane futhi ibe nokuma kwe-convex kancane ebusweni ngemva kokusetshenziswa kokugcwalisa.

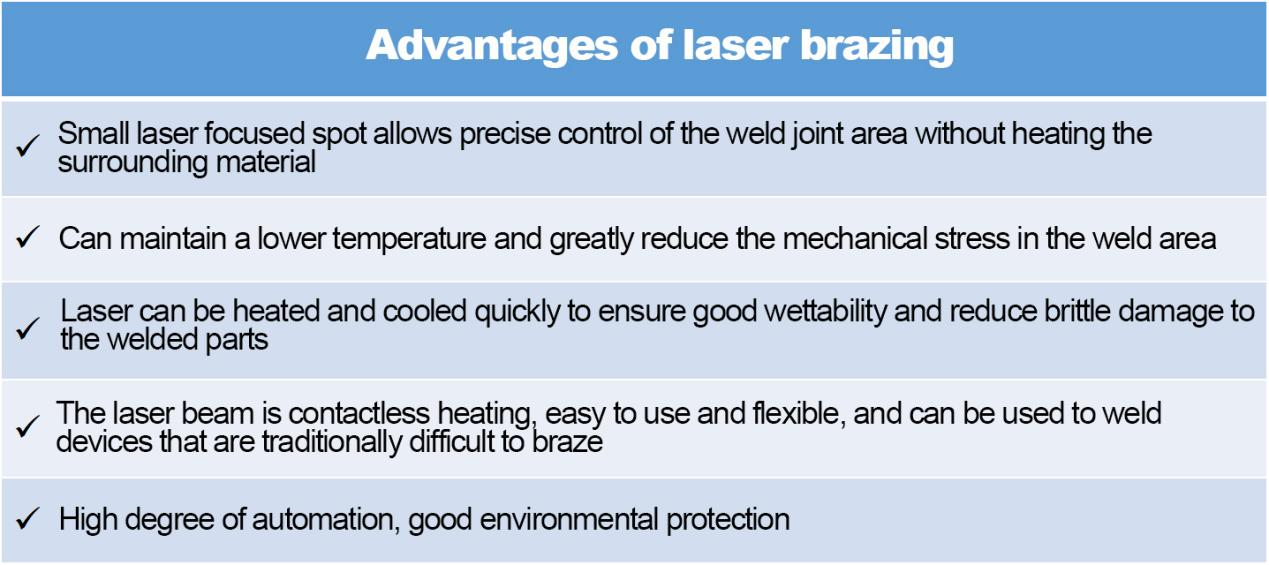

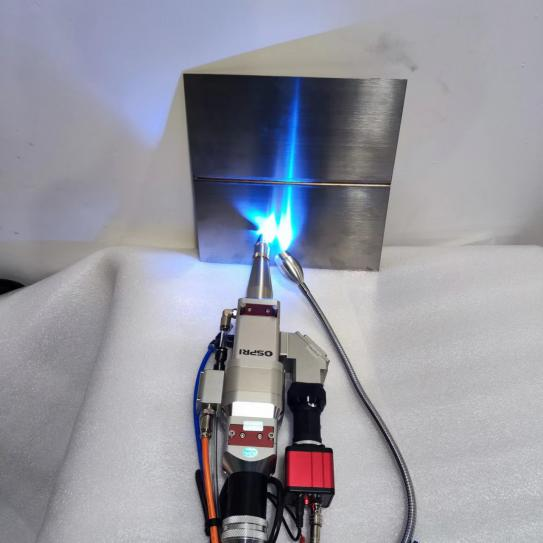

I-Laser Brazing

Ngokungafani ne-fusion welding, encibilikisa izingxenye ezimbili ezishiselwe ngasikhathi sinye, i-brazing ingeza into yokugcwalisa enephuzu lokuncibilika eliphansi kunesisekelo se-weld surface, incibilikisa into yokugcwalisa ukugcwalisa igebe ekushiseni okuphansi kunokuncibilika kwesisekelo. iphuzu futhi liphakeme kunendawo yokuncibilika yezinto zokugcwalisa, bese liyajiya ukuze kwakheka i-weld eqinile.

I-Brazing ifaneleka kumadivayisi e-microelectronic angezwani nokushisa, amapuleti amancane, nezinto zensimbi eziguquguqukayo.

Ngaphezu kwalokho, ingaphinde ihlukaniswe ngokuthi i-soft brazing (<450 °C) kanye ne-hard brazing (>450 °C) kuye ngezinga lokushisa okushisisa ngalo okokusebenza kokubhsa.

I-Dual Beam Laser Welding

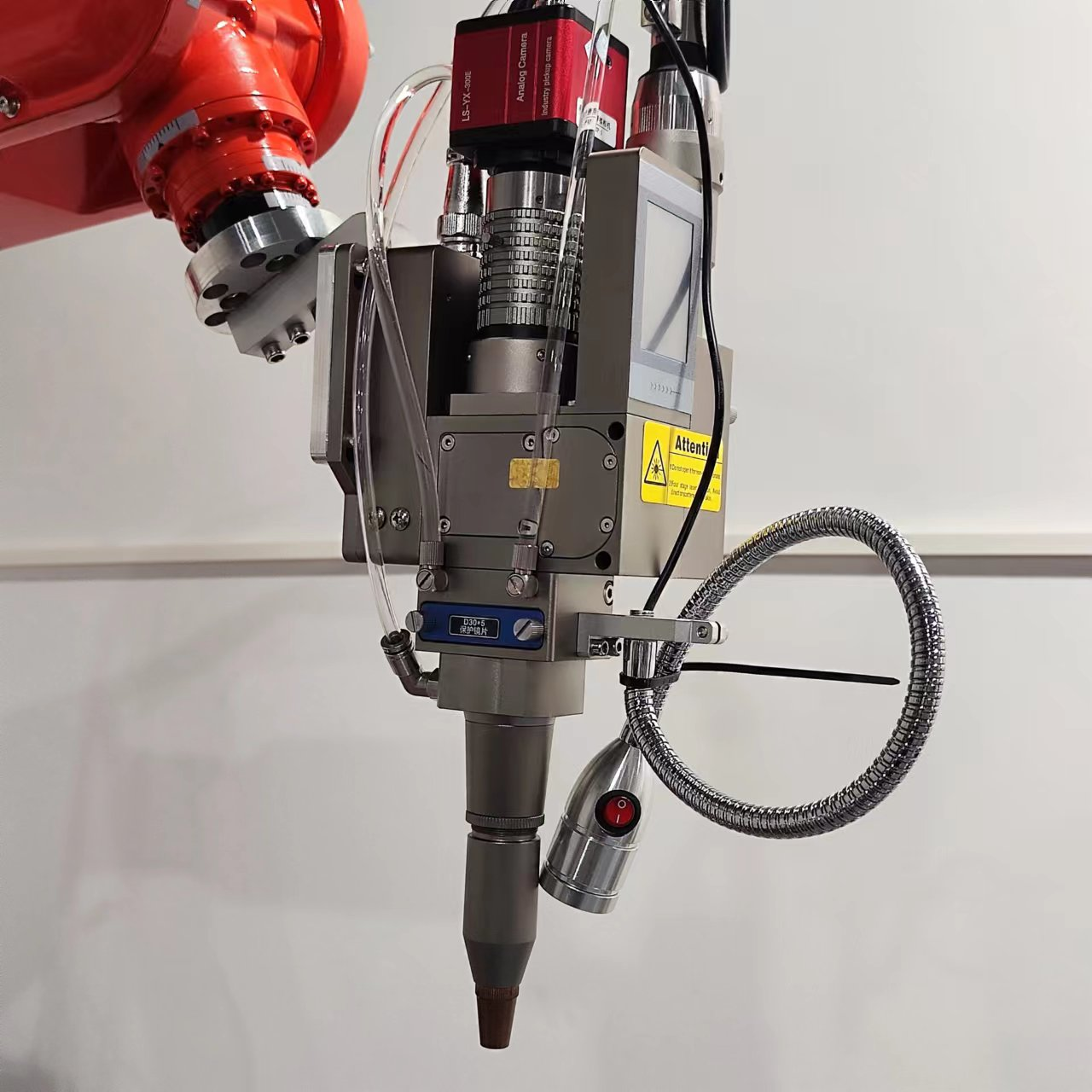

I-Dual-beam welding ivumela ukulawula okuguquguqukayo nokulula kwesikhathi kanye nendawo ye-laser, ngaleyo ndlela kulungiswe ukusatshalaliswa kwamandla.

Isetshenziswa kakhulu ukushisela i-laser ye-aluminium ne-magnesium alloys, i-splice kanye ne-lap plate welding yezimoto, i-laser brazing kanye ne-deep fusion welding.

I-double beam ingatholwa ngama-lasers amabili azimele noma ngokuhlukaniswa kwe-beam nge-splitter ye-beam.

Imishayo emibili ingaba inhlanganisela yama-lasers anezici zesizinda sesikhathi esihlukile (i-pulsed vs. continuous), amaza ahlukene (mid-infrared vs. Wavelengths ebonakalayo) namandla ahlukene, angakhethwa ngokuya ngezinto ezicutshunguliwe zangempela.

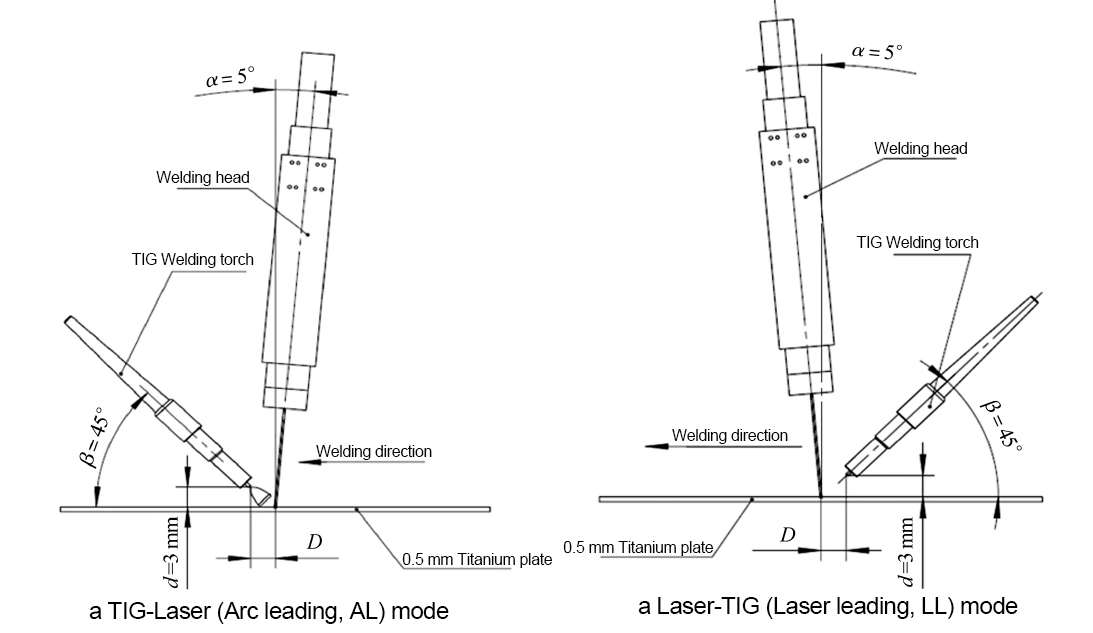

4.Laser Composite Welding

Ngenxa yokusetshenziswa kwe-laser beam njengokuphela komthombo wokushisa, umthombo owodwa wokushisa we-laser welding unezinga eliphansi lokuguqulwa kwamandla kanye nezinga lokusebenzisa, i-weld base port interface kulula ukukhiqiza ukungahambi kahle, ukukhiqiza kalula ama-pores kanye nemifantu kanye nokunye ukushiyeka, ukuze uxazulule le nkinga, ungasebenzisa izici zokushisa zeminye imithombo yokushisa ukuze uthuthukise ukushisisa kwe-laser endaweni yokusebenza, ngokuvamile ebizwa ngokuthi i-laser composite welding.

Uhlobo oluyinhloko lwe-laser composite welding yi-welding eyinhlanganisela ye-laser ne-arc kagesi, 1 + 1> 2 umphumela umi kanje.

ngemuva kwe-laser beam eduze kwe-arc esetshenzisiwe,ukuminyana kwama-electron kuncipha kakhulu, ifu le-plasma elakhiwe yi-laser welding liyahlanjululwa, okuyintoingenza izinga lokumuncwa kwe-laser libe ngcono kakhulu, kuyilapho i-arc ku-base preheating izothuthukisa futhi izinga lokumunca lelaser.

2. ukusetshenziswa kwamandla okuphezulu kwe-arc kanye nengqikithiukusetshenziswa kwamandla kuzokwenyuka.

I-3, indawo yokusebenza ye-laser welding incane, kulula ukubangela ukungahambi kahle kwechweba lokushisela, kuyilapho isenzo esishisayo se-arc sikhulu, esingabaukunciphisa ukungahambi kahle kwechweba lokushisela. Ngesikhathi esifanayo, i-ikhwalithi yokushisela nokusebenza kahle kwe-arc kuyathuthukiswangenxa yokugxila kanye nomphumela oqondisayo we-laser beam ku-arc.

I-4, i-laser welding enezinga eliphezulu lokushisa eliphakeme, indawo enkulu ethinteke ukushisa, ukupholisa okusheshayo kanye nesivinini sokuqina, ukukhiqiza kalula imifantu nezimbotshana; ngenkathi indawo ye-arc ethinteke ukushisa incane, enganciphisa izinga lokushisa, ukupholisa, isivinini sokuqina,inganciphisa futhi iqede ukukhiqizwa kwama-pores kanye nemifantu.

Kunezindlela ezimbili ezivamile zokushisela inhlanganisela ye-laser-arc: i-laser-TIG composite welding (njengoba kuboniswe ngezansi) kanye ne-laser-MIG composite welding.

Kukhona nezinye izinhlobo zokushisela ezifana ne-laser ne-plasma arc, i-laser kanye ne-inductive heat source compound welding.

Mayelana ne-MavenLaser

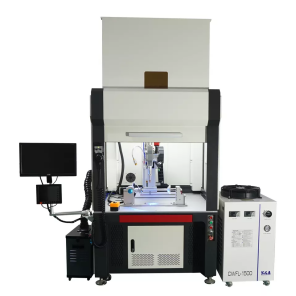

I-Maven Laser ingumholi wohlelo lokusebenza lwezimboni ze-laser e-China kanye nomhlinzeki ogunyaziwe wezixazululo zomhlaba jikelele zokucutshungulwa kwe-laser. Sikuqonda ngokujulile ukuthambekela kwentuthuko yemboni yokukhiqiza, sicebisa njalo imikhiqizo yethu nezisombululo, sigcizelela ekuhloleni ukuhlanganiswa kwe-automation, informationization kanye nobuhlakani nemboni yokukhiqiza, sihlinzeka ngemishini yokushisela i-laser, imishini yokumaka i-laser, imishini yokuhlanza i-laser nobucwebe begolide nesiliva. imishini yokusika yezimboni ezihlukahlukene kuhlanganise nochungechunge lwamandla agcwele, futhi ngokuqhubekayo sikhulise ithonya lethu emkhakheni wemishini ye-laser.

Isikhathi sokuthumela: Jan-13-2023