Kungani ukhetheQCW isikhunta ukulungisa fibre optic welding mach

Ukulungisa isikhunta kuyinqubo ebucayi embonini yokukhiqiza, futhi ukuba namathuluzi afanele kanye nemishini kubalulekile ekuzuzeni imiphumela yezinga eliphezulu. Elinye ithuluzi elinjalo eliye laduma eminyakeni yamuva nje ukulungiswa kwesikhunta se-QCWi-fiber welder. Lo mshini omusha ushintsha inqubo yokulungisa isikhunta, unikeze uhla lwezinzuzo nezici eziwenza kube ukukhetha kokuqala kubakhiqizi nezingcweti zokulungisa isikhunta. Kulesi sihloko, sizohlola izici zemishini yokushisela isikhunta futhi sihlole ukuthi yini eyenza umshini wokushisela we-QCW Mold Repair Fiber Welding ugqame.

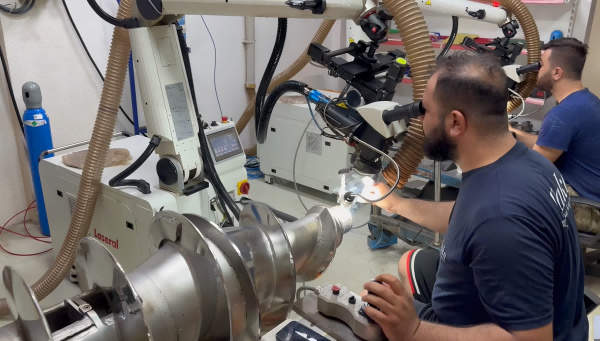

Imishini yokushisela isikhuntazenzelwe ukulungisa nokulungisa isikhunta esisetshenziswa ezinqubweni ezehlukene zokukhiqiza. Le mishini isebenzisa ubuchwepheshe obuphambili bokushisela ukulungisa imifantu, ama-chips nokunye ukulimala kwesikhunta, iqinisekisa ukuthi ingaqhubeka nokukhiqiza izingxenye ezisezingeni eliphezulu. Lapho ukhetha umshini wokubumba isikhunta, kunezici ezimbalwa ezibalulekile okufanele uzicabangele. Lokhu kubandakanya ukunemba, ukusebenza kahle, ukuguquguquka nokusebenziseka kalula.

Umshini Welding we-QCW Mold Repair Fiber Welding udlula zonke lezi zindawo, okuwenza ube yisinqumo esingcono kakhulu sochwepheshe bokukhanda isikhunta. Ake sibhekisise izici ezenza lo mshini uhluke emqhudelwaneni.

Ukunemba kuyisici esiyinhloko ekulungiseni isikhunta ngoba ngisho neziphambeko ezincane kakhulu zingathinta ikhwalithi yengxenye eqediwe. Umshini wokushisela isikhunta we-QCW ufakwe ubuchwepheshe be-laser obuthuthukisiwe bokushisela okunembile nokunembile. Leli zinga lokunemba liqinisekisa ukuthi isikhunta esilungisiwe sigcina ubukhulu baso bangempela kanye nokucaciswa, sikhiqize izingxenye ezihlangabezana nezindinganiso zekhwalithi ephezulu.

Ukusebenza kahle kungenye into ebalulekile yemishini yokushisela isikhunta. Umshini we-QCW wokukhanda isikhunta we-fiber optic welding uhlanganisa isivinini sokushisela esisheshayo, esivumela ukulungiswa okusheshayo nokunciphisa isikhathi sokuphumula ngesikhathi sokukhiqiza. Lokhu kusebenza kahle kubalulekile ekugcineni ukukhiqiza kanye nokuhlangabezana nezinsuku zokugcina zokukhiqiza, okwenza imishini ye-QCW ibe yimpahla ebalulekile yabakhiqizi.

I-Versatility nayo iwukucatshangelwa okubalulekile lapho ukhetha umshini wokushisela isikhunta. I-QCW isikhunta sokulungisa i-fiber welder iyakwazi ukulungisa izinto ezihlukahlukene zokubumba, okuhlanganisa insimbi, i-aluminium nama-alloys ahlukahlukene. Lokhu kuguquguquka kuyenza ilungele izinhlelo zokusebenza zokukhiqiza ezahlukahlukene, inikeze ukuguquguquka kochwepheshe bokulungisa isikhunta.

Ukusebenziseka kalula kuyisici esibalulekile kunoma iyiphi into esetshenziswayo, futhi Umshini Wokushisela I-QCW Mold Repair Fiber uklanywe ngezici ezisebenziseka kalula ezivumela opharetha bamazinga ahlukahlukene wamakhono ukuthi bawusebenzise. Izilawuli ezinembile, idizayini ye-ergonomic nokuqeqeshwa okuphelele nokusekelwa kuqinisekisa ukuthi abasebenzisi bangakwazi ukusingatha umshini ngokushesha futhi bathole imiphumela emihle.

Ngaphezu kwalezi zici, kunezizathu ezimbalwa eziqondile zokuthi kungani i-QCW Mold Repair Fiber Welder iyisinqumo sokuqala sochwepheshe bokukhanda isikhunta. Enye yezinzuzo eziyinhloko zalo mshini yikhono lokwenza ukulungisa ngaphandle kwesidingo sokushisa okubanzi noma ukwelashwa kokushisa kwe-post-weld. Lokhu akugcini nje ngokusindisa isikhathi, futhi kunciphisa ingozi yokuguqulwa kwe-thermal futhi kugcina ubuqotho besikhunta.

Ngaphezu kwalokho, umshini wokukhanda i-fiber welding we-QCW uhlanganisa amandla aphezulu okushisela kanye nekhwalithi, ukuqinisekisa ukuthi isikhunta esilungisiwe singakwazi ukumelana nobunzima bokusetshenziswa okuqhubekayo phakathi nenqubo yokukhiqiza. Lokhu kuqina kubalulekile ekwandiseni impilo yesikhunta kanye nokunciphisa imvamisa yokulungisa, ekugcineni konge isikhathi nemali kubakhiqizi.

Esinye isizathu esiphoqayo sokukhetha i-QCW isikhunta sokulungisa i-fiber welder yikhono layo lokufeza ama-welds angenamthungo ngokwakhiwa kwezinto ezincane. Lokhu kubangela isiphetho esihlanzekile, esinembayo ngaphandle kwesidingo sokuqedela nokupholishwa kwangemuva kokushisela. Imishini ye-QCW iyakwazi ukukhiqiza amashisela ekhwalithi ephezulu anokuhlanekezelwa kwezinto ezincane, okwenza imishini ye-QCW ihluke ezindleleni zendabuko zokushisela.

Ngaphezu kwalokho, umshini wokukhanda i-fiber welding we-QCW ufakwe izinhlelo zokuqapha nokulawula ezithuthukisiwe ukuze kuqinisekiswe ikhwalithi yokushisela engaguquki futhi kuncishiswe ubungozi bokukhubazeka. Leli zinga lokuzenzakalela nokunemba linciphisa ukuthembela ekhonweni lomsebenzisi nolwazi, okwenza umshini ufinyeleleke kubangeni elibanzi labasebenzisi.

Kafushane, umshini wokushisela we-QCW Mold Repair Fiber Welding uhlanganisa ukunemba, ukusebenza kahle, ukuguquguquka nokusebenziseka kalula, okwenza kube ukukhetha kokuqala kochwepheshe bokukhanda isikhunta. Ikhono layo lokuhlinzeka ngama-welds ekhwalithi ephezulu, ukuhlanekezela okushisayo okuncane, amandla aphakeme kanye nokuqeda okungenamthungo kwenza kube yisixazululo esihle kakhulu sokulungisa isikhunta. Ngemishini ye-QCW, abakhiqizi bangakwazi ukufeza ukulungiswa okuthembekile futhi okuhlala isikhathi eside, ekugcineni kusize ukwandisa ukukhiqiza nokugcina izindleko. Uma kukhulunywa ngokulungiswa kwesikhunta, ukukhetha okokusebenza okufanele kubalulekile, futhi umshini wokushisela we-QCW Mold Repair Fiber ngokungangabazeki uwukukhetha okuhamba phambili embonini.

Isikhathi sokuthumela: Sep-06-2024

.png)

.png)

.png)