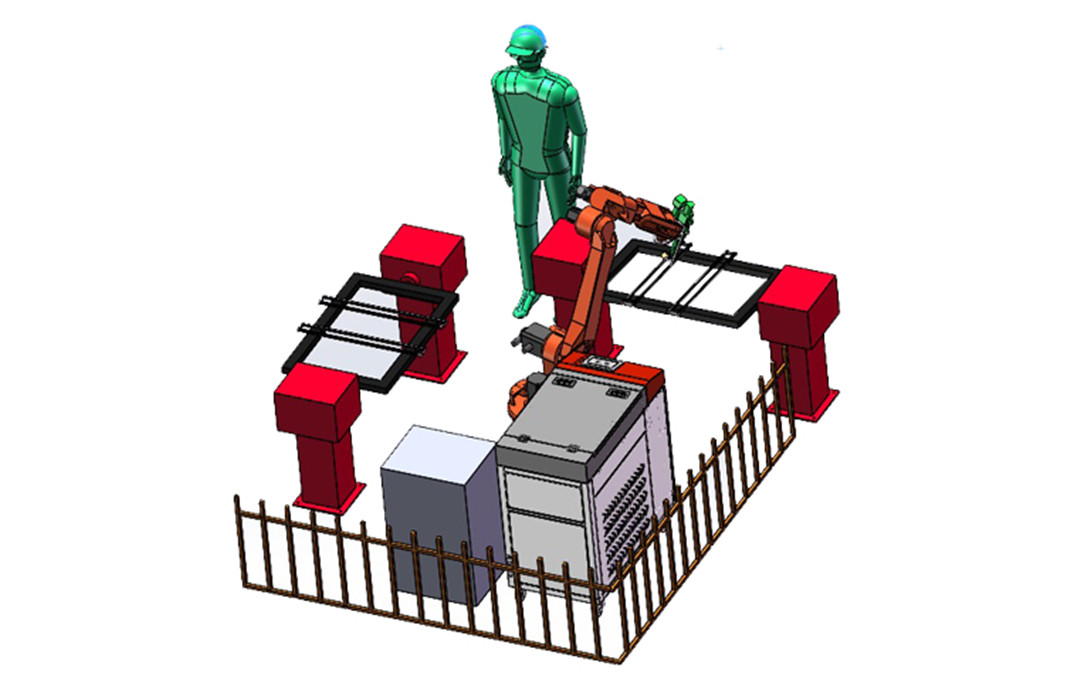

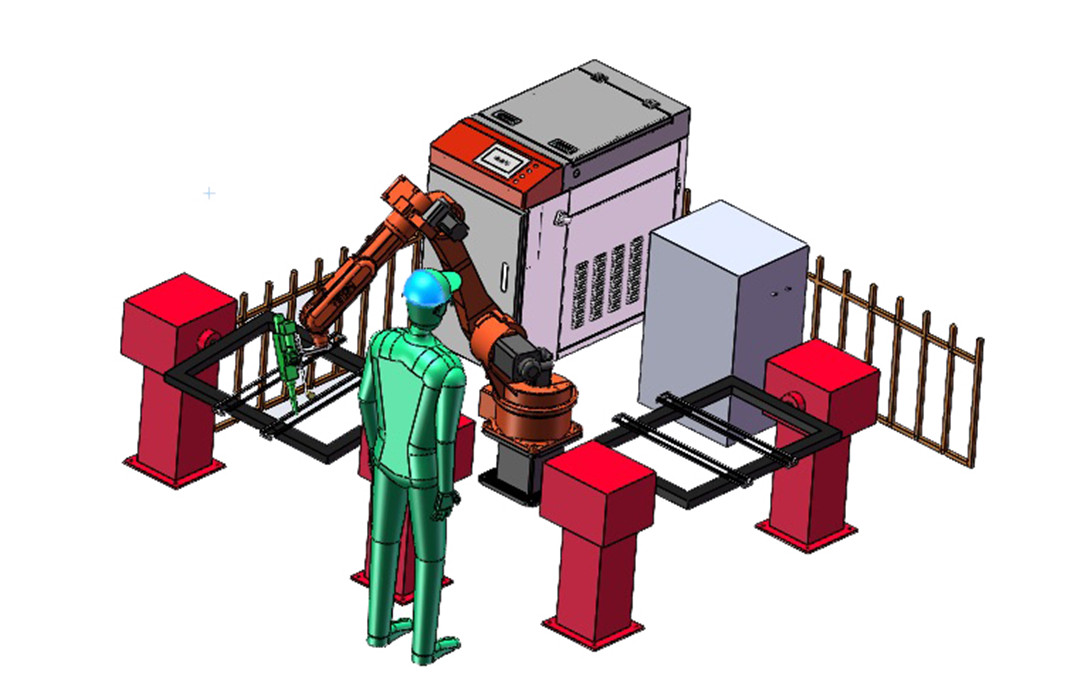

I-Robotic Fiber Laser Welding Machine

Izici zezisetshenziswa:

1. Ukusebenzisa ukunyakaza kwe-robotic, okulungele ukushisela isikhala sefomethi enkulu, kungaba ukuxhumana kwe-axis eziyisithupha.

2. Ingakwazi ukushisela kunoma iyiphi indawo, ibone ngempela ukushisela okuzenzakalelayo kwanoma iyiphi i-trajectory emkhathini.

3. Ukunemba kokuphindaphinda okuphezulu, kungaphinda ukushisela izikhathi eziningi ngaphandle kwephutha, izinga le-weld lizinzile.

4. Ingathatha indawo yokusebenza kwezandla, futhi ingashisela i-laser izinkambu eziyinkimbinkimbi neziyingozi.

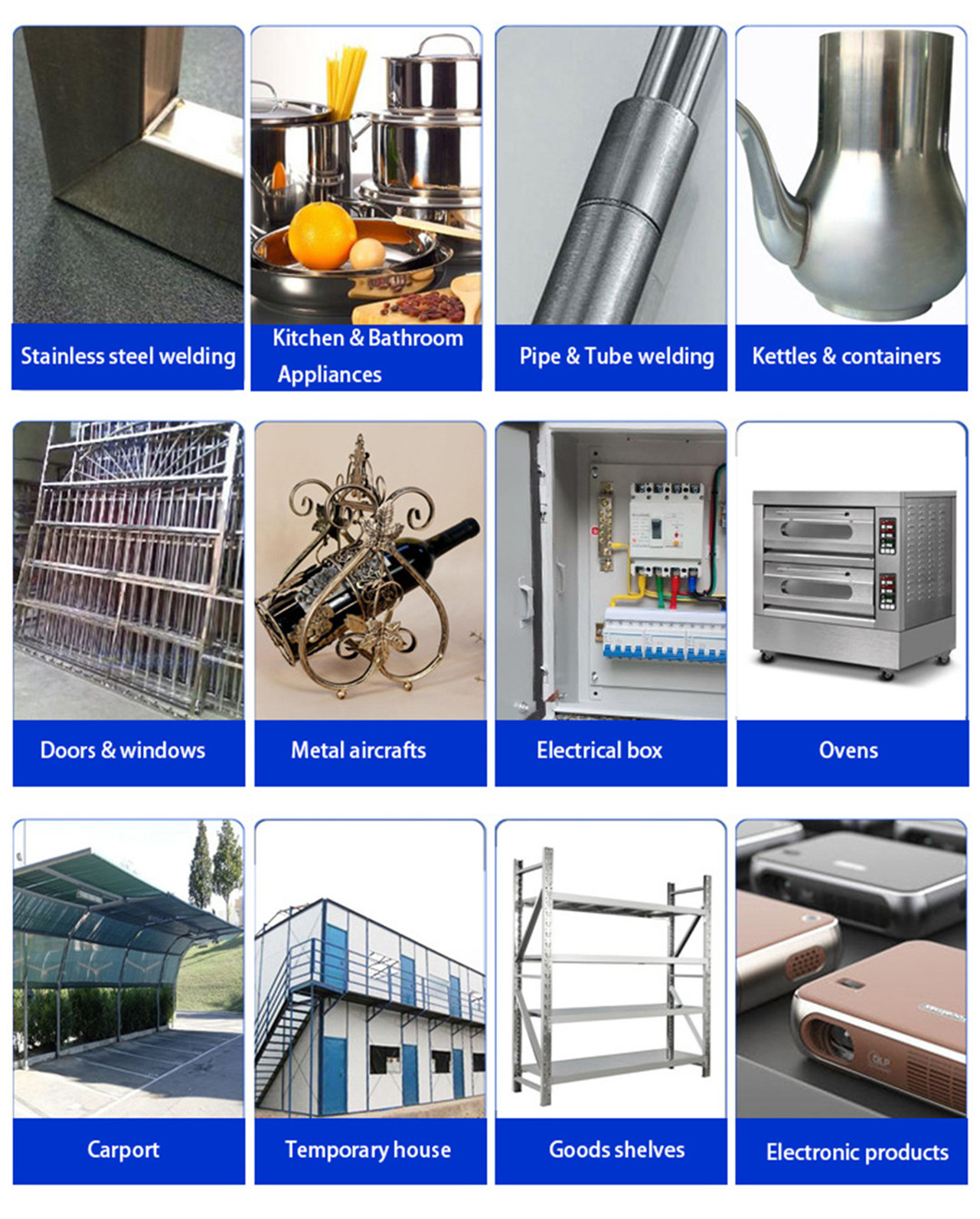

Izindawo zokufaka isicelo:

Umzimba ozenzakalelayo, i-auto steel plate, i-clutch plate, izinkambu zokushisela ezinzima neziyinkimbinkimbi, izingxenye ze-microelectronic, izingxenye ezinembayo, izingxenye zedijithali zezinga eliphezulu, izixhumi ze-fiber optic, izisetshenziswa zezokwelapha, isikhunta esikhulu sokushisela, ukubumba umjovo nokunye ukushisela.

I-PROFESSIONAL WElding SOLUTION

I-Wire Feeder kanye neWelding igxile ku-Control Pedal

0.08mm Ukunemba Kwendawo Yerobhothi

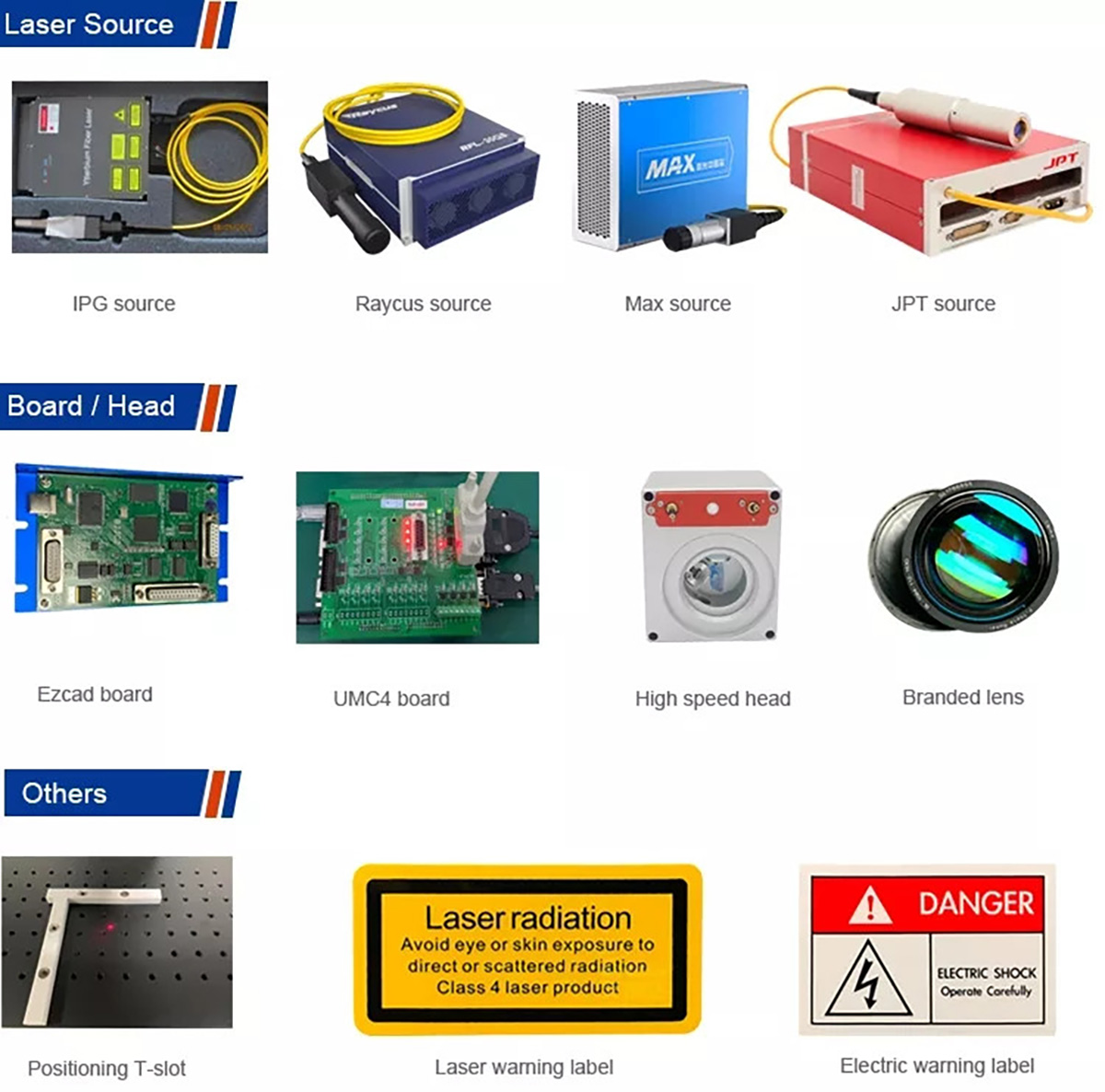

Raycus Max JPT IPG Laser Source Optional

Ukwenza ngokwezifiso Isistimu Yonke

| Igama Lomkhiqizo | I-Robot Automatic Laser Welding MachineI-MLA-W-A01 |

| Ubude begagasi | 1070+/-10 nm |

| Laser Amandla | 1000W 1500W 2000W 3000W |

| Ukulungiswa kwamandla | 10-100% |

| Ubude be-Fiber | Okujwayelekile 10m noma Cacisa |

| Izindlela Zokusebenza | CW/Pulse |

| Ibanga Lejubane | 0-120 mm |

| Ukuqina kwe-Weld | 0.5-6 mm |

| Imfuneko ye-Welding Gap | < 1 mm |

| I-Modulation Frequency | 20KHZ |

| Vula/vala Isikhathi | 20 Us |

| Izinga Lokushisa Lokusebenza | 15-35 ℃ |

| Ukunikezwa kwamandla kagesi | 220V/50HZ/30A |

| Izindlela Zokuphola | Amanzi Apholile Ngaphakathi |

| Usayizi Womshini | 990*540*1030 mm |

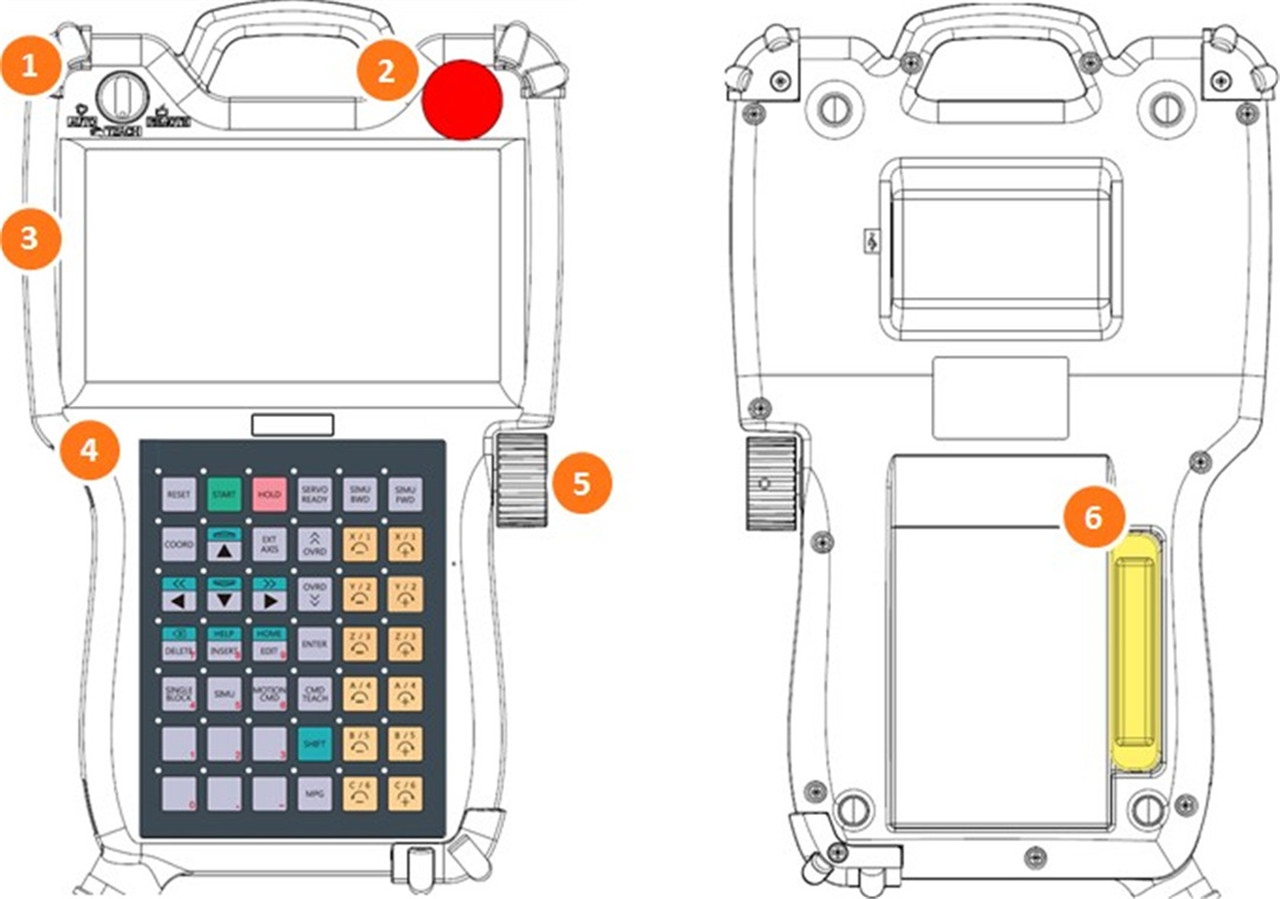

KULULA UKUSEBENZA

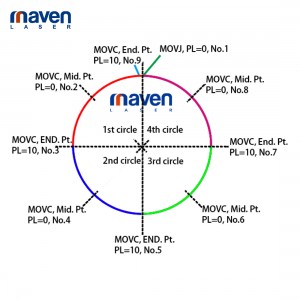

Isilawuli sokusebenzisa esinobungane sokubambisana okulula ne-fiber laser welding umyalo womsebenzi

UKULAWULA UKUHLANGANISA

Ukuhlanganiswa kwekhabhinethi yokulawula ukulawula umsebenzi wokuphakela ngocingo. Futhi amandla e-laser angakhuphuka futhi awe kancane ukuze avimbele ukuvutha ngaphezulu. Ukukhuphuka nokuwa kancane kunenzuzo ikakhulukazi ekushiseleleni amapuleti amancane. Lapho i-manipulator iqeda, ngokuvamile kulula ukushisela ngepuleti.

I-LASE INTERGRATUION

Ngaphezu kokulungisa imingcele yokushisela ohlelweni lwe-laser. Iphinde ibe nemisebenzi yokukhanya kwenkomba yesimo sesistimu ngayinye, ukushintsha kwamanzi kagesi, nesikhumbuzi esizenzakalelayo sokuvikela ilensi.

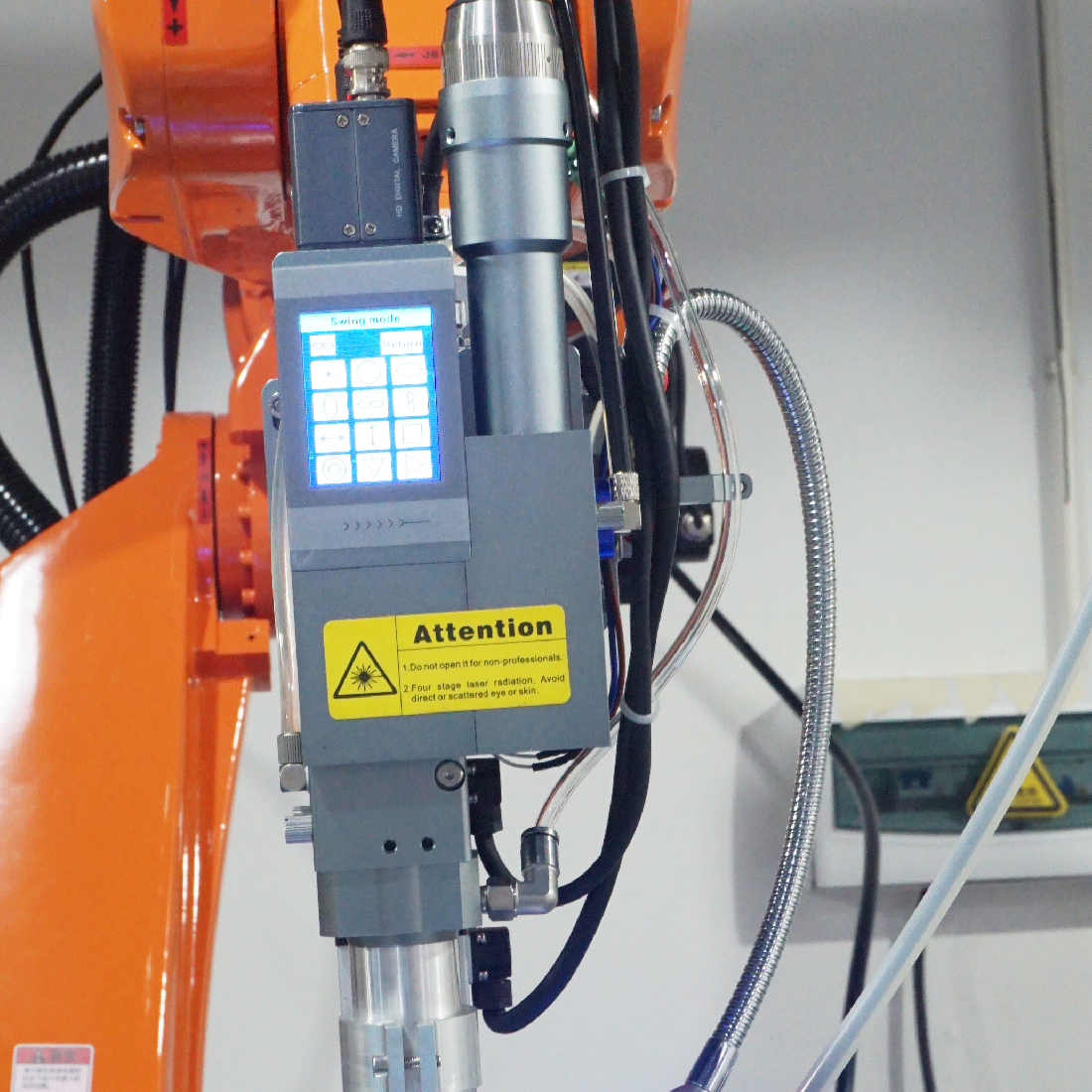

UKUHLANGANYELA KWEKHANDA

Integrated welding head, CCD ekhanda, amandla adjustable, auto focus, operation elula.

KULULA UKUSEBENZA

Izinkinobho zependant yokufundisa zilula futhi ziqondakala kalula, futhi uhlelo lokufundisa lungafundwa futhi lusetshenziswe ngokushesha. Uma ukusebenza kungalungile, umshini uyama ngokuzenzekelayo ukuze ugweme ingozi yokulimala kwemishini.

SEBENZA NGEMPELA

Uma isihleliwe, ingasetshenziswa ngaso sonke isikhathi. I-MavenLaser Robot Arm isekela amahora angama-24 omsebenzi oqhubekayo ngokunemba okuphezulu nesivinini esikhulu. Ukusebenza okuzenzakalelayo ngokugcwele, irobhothi lingaqedela umsebenzi wabantu abangaphezu kuka-2-3 ngosuku.

IZINDLEKO EZIPHANSI

Utshalomali lwesikhathi esisodwa, izinzuzo zesikhathi eside. Impilo yesevisi yerobhothi leMavenLaser amahora angama-80,000, okulingana neminyaka engaphezu kwengu-9 yomsebenzi ongaphazamiseki wamahora angama-24. Izonga kakhulu izindleko zabasebenzi kanye nezindleko zokuphatha abasebenzi, futhi ixazulula izinkinga ezinjengobunzima bokuqasha abantu.

IPHEPHILE FUTHI IYATHEMBEKA

Ingalo yerobhothi ye-MavenLaser ifakwe izindlela zokuvikela ukuphepha kwe-photoeletric. Lapho izinto zakwamanye amazwe zingena endaweni yokusebenza, zingahlaba umkhosi ngokuzenzakalelayo futhi zimise umsebenzi ukugwema ingozi esisebenzini.

AMANDLA APHEPHILE NOKUTHULA

Isakhiwo somugqa wemishini ye-MavenLaser ilula futhi icocekile, akukho msindo, ingalo yerobhothi ekhanyayo neqinile, ukusetshenziswa kwamandla okuphansi, ukufakwa kwe-saxing kwamandla nokuvikelwa kwemvelo.

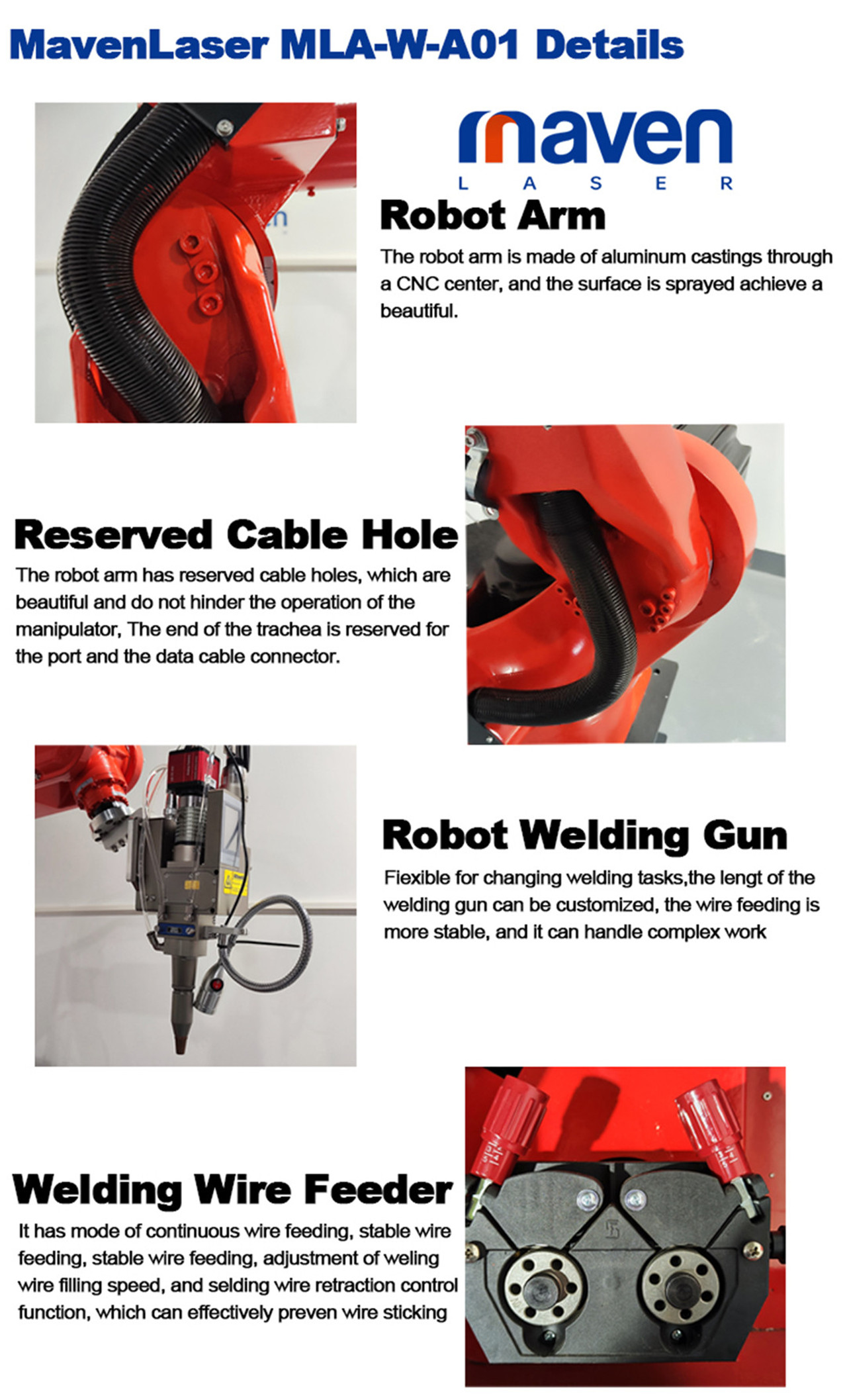

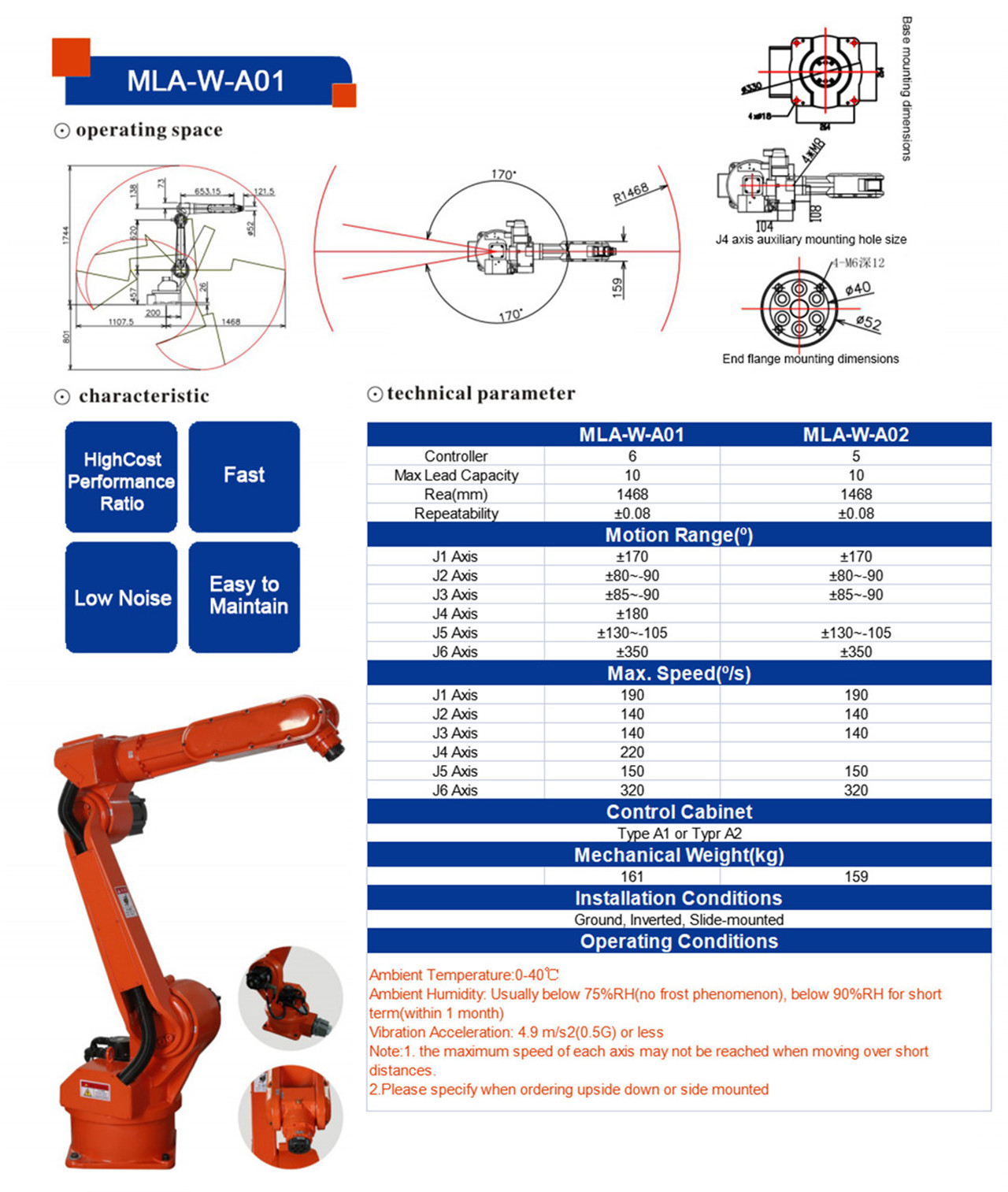

Ingalo yerobhothi

Ingalo yerobhothi yenziwe nge-aluminium castings ngokusebenzisa isikhungo se-CNC, futhi ingaphezulu liyafafazwa lizuze okuhle.

Reserved Cable Hole

Ingalo yerobhothi inezimbobo zekhebula ezigodliwe, ezinhle futhi ezivimbela ukusebenza kwe-manipulator, ukuphela kwe-trachea kugcinelwe ichweba kanye nesixhumi sekhebula ledatha.

Robot Welding Gun

I-Flexible yokushintsha imisebenzi yokushisela, ubude besibhamu sokushisela bungenziwa ngokwezifiso, ukondla ngocingo kuzinzile, futhi kungakwazi ukuphatha umsebenzi oyinkimbinkimbi.

I-Welding Wire Feeder

Inemodi yokudla okuqhubekayo kocingo, ukondla ucingo oluzinzile, ukondla ucingo oluzinzile, ukulungiswa kwesivinini sokugcwalisa i-welling wire, kanye nomsebenzi wokulawula ukuhoxiswa kocingo, okungavimbela ngempumelelo ukunamathela kocingo.

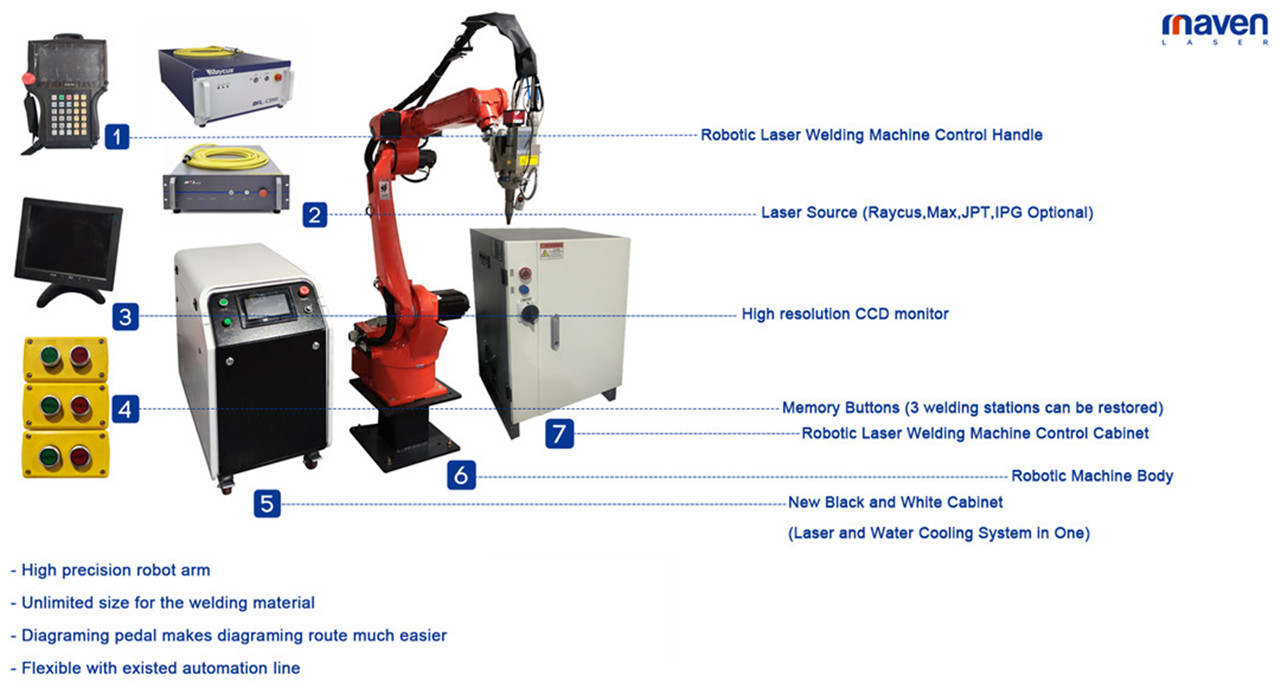

● Umthombo weLaser(Raycus,Max,JPT,IPG Optional)

● Imonitha ye-CCD enesinqumo esiphezulu

● Izinkinobho Zenkumbulo(iziteshi zokushisela ezi-3 zingabuyiselwa)

● Ikhabhinethi Entsha Emnyama Nokumhlophe(Isistimu Yokupholisa Ilaza Namanzi Eyodwa)

● Umzimba Womshini Werobhothi

● IKhabhinethi Yokulawula Umshini We-Laser Welding

● Ingalo yerobhothi enembe kakhulu

● Usayizi ongenamkhawulo wezinto zokushisela

● Iphedali yomdwebo yenza umzila womdwebo ube lula kakhulu

● Ivumelana nezimo ngolayini ozenzakalelayo okhona

| I-MLA-W-A01 | I-MLA-WA02 | |

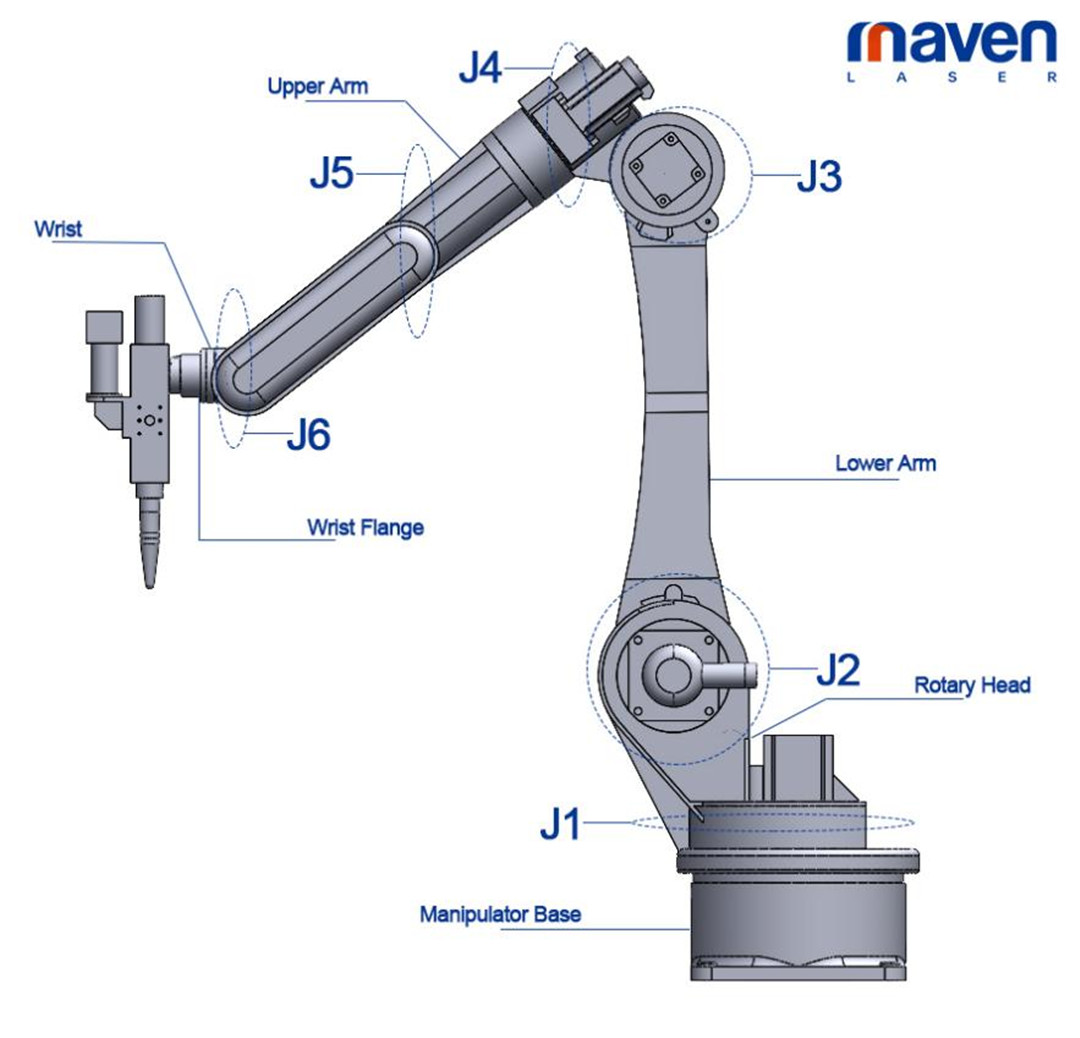

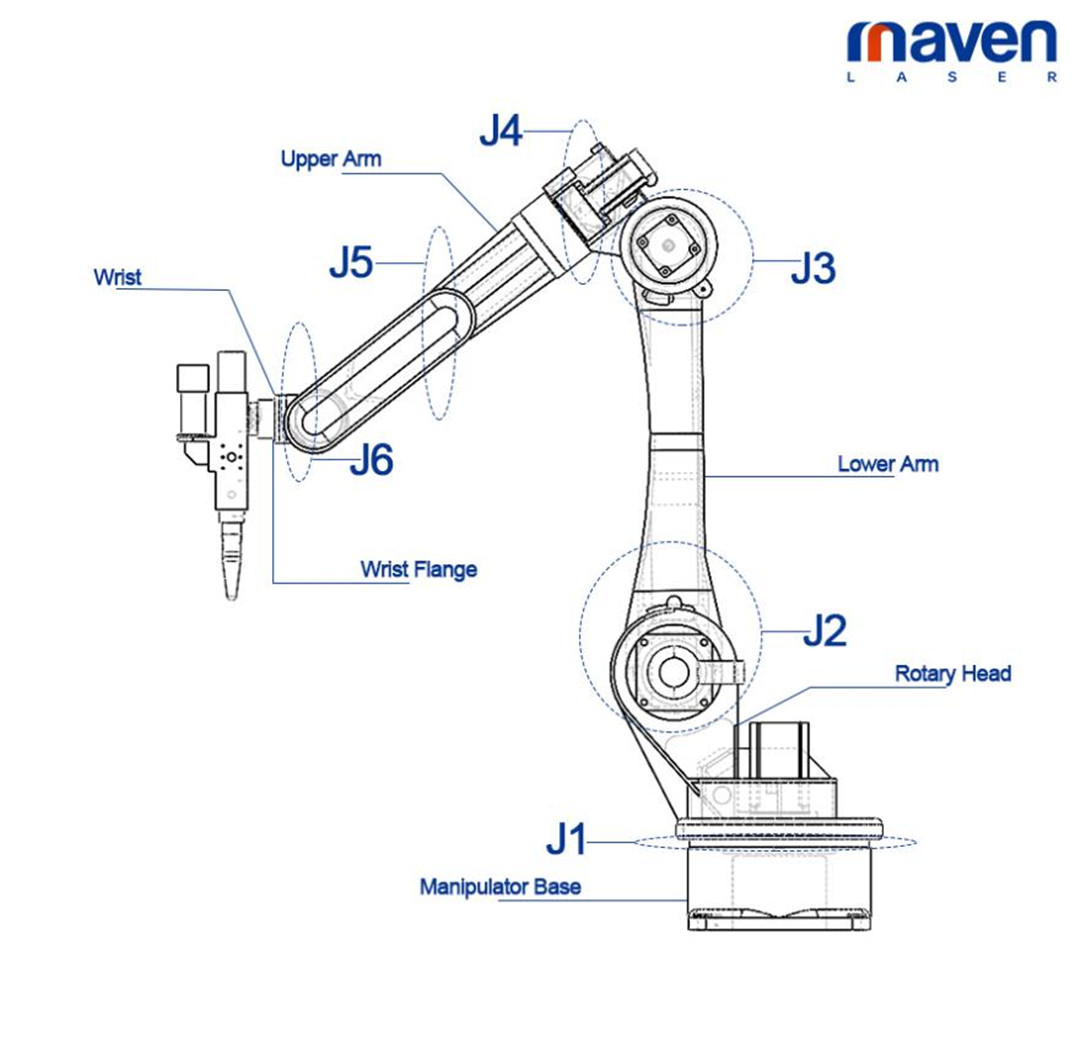

| Isilawuli | 6 | 5 |

| Amandla Okuhola Amakhulu | 10 | 10 |

| I-Rea(mm) | 1468 | 1468 |

| Ukuphindaphinda | ±0.08 | ±0.08 |

| Ibanga Lokunyakaza(°) | ||

| J1 ekseni | ±170 | ±170 |

| I-J2 eksisi | ±80~-90 | ±80~-90 |

| I-J3 eksisi | ±85~-90 | ±85~-90 |

| I-J4 eksisi | ±180 |

|

| J5 ekseni | ±130~-105 | ±130~-105 |

| J6 ekseni | ±350 | ±350 |

| Ubukhulu. Isivinini(°/s) | ||

| J1 ekseni | 190 | 190 |

| I-J2 eksisi | 140 | 140 |

| I-J3 eksisi | 140 | 140 |

| I-J4 eksisi | 220 |

|

| J5 ekseni | 150 | 150 |

| J6 ekseni | 320 | 320 |

| Ikhabhinethi yokulawula | ||

| Thayipha A1 noma Uhlobo A2 | ||

| Isisindo Somshini(kg) | ||

|

| 161 | 159 |

| Imibandela Yokufaka | ||

| Iphansi, Iguquliwe, Ikhwezwe ngesilayidi | ||

| Izimo zokusebenza | ||

I-Ambient Temperature:0-40℃

Umswakamo We-Ambient: Ngokuvamile ube ngaphansi kuka-75%RH(akukho mkhuba wesithwathwa), ngaphansi kuka-90%RH isikhathi esifushane(phakathi nenyanga engu-1)

Ukusheshisa Ukudlidliza::4.9 m/s2(0.5G) noma ngaphansi

Qaphela:1.isivinini esiphezulu se-eksisi ngayinye singase singafinyeleli lapho uhamba amabanga amafushane.

2.Sicela ucacise lapho u-oda ubheke phansi noma ubekwe eceleni

1. Ukushintsha Imodi

2. I-Emergency Stop

3. Isikrini sokubonisa

4. Izikhiye Zenyama

5. MPG (Manuel Pulse Generator)

6. Ivumela Idivayisi