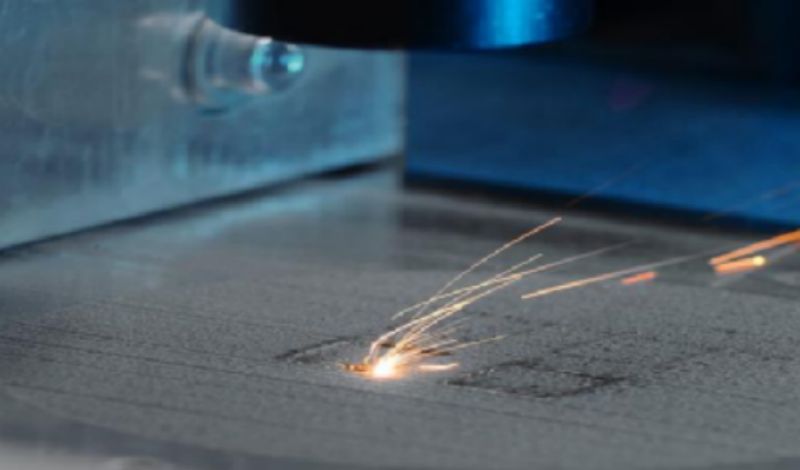

Eminyakeni yamuva, ngenxa yentuthuko esheshayo yemboni yamandla entsha, i-laser welding ingene ngokushesha kuyo yonke imboni yamandla amasha ngenxa yezinzuzo zayo ezisheshayo nezizinzile. Phakathi kwazo, imishini yokushisela i-laser ibamba ingxenye ephezulu kakhulu yezicelo kuyo yonke imboni yamandla entsha.

I-laser weldingngokushesha isibe yisinqumo sokuqala kuyo yonke imikhakha yempilo ngenxa yejubane layo elisheshayo, ukujula okukhulu, nokuwohloka okuncane. Ukusuka ekushiseleleni amabala kuya kumashisela ezinqeni, ama-bulkup nama-seal weld,laser weldinginikeza ukunemba nokulawula okungenakuqhathaniswa. Idlala indima ebalulekile ekukhiqizweni kwezimboni nasekukhiqizeni, okuhlanganisa imboni yezempi, ukunakekelwa kwezokwelapha, i-aerospace, izingxenye zezimoto ze-3C, i-mechanical sheet metal, amandla amasha nezinye izimboni.

Uma kuqhathaniswa nobunye ubuchwepheshe bokushisela, i-laser welding inezinzuzo zayo eziyingqayizivele kanye nokubi.

Inzuzo:

1. Isivinini esisheshayo, ukujula okukhulu kanye nokuguqulwa okuncane.

2. I-Welding ingenziwa ekushiseni okujwayelekile noma ngaphansi kwezimo ezikhethekile, futhi imishini yokushisela ilula. Isibonelo, i-laser beam ayikhukhuleki endaweni ye-electromagnetic. Ama-Lasers angashisela endaweni engenalutho, emoyeni noma endaweni ethile yegesi, futhi angashisela izinto ezisetshenziswa engilazini noma ezikhanyelayo kuyi-laser.

3. Ingakwazi ukushisela izinto eziphikisayo njenge-titanium ne-quartz, futhi ingashisela izinto ezingafani ngemiphumela emihle.

4. Ngemuva kokuthi i-laser igxile, ukuminyana kwamandla kuphezulu. Ukubukeka kwe-aspect ratio kungafinyelela ku-5:1, futhi kungafinyelela ku-10:1 uma kushiselwa amadivayisi anamandla amakhulu.

5. Micro welding ingenziwa. Ngemuva kokuthi i-laser beam igxiliwe, indawo encane ingatholakala futhi ingabekwa ngokunembile. Ingasetshenziswa ekuhlanganiseni nasekushiseleni ama-workpieces amancane namancane ukuze kuzuzwe ukukhiqizwa kwenqwaba okuzenzakalelayo.

6. Ingakwazi ukushisela izindawo okunzima ukufinyelela kuzo futhi yenze i-welding ekude yokuxhumana nabantu, ngokuguquguquka okukhulu. Ikakhulukazi eminyakeni yakamuva, ubuchwepheshe bokucubungula i-LAG ye-YAG sebamukele ubuchwepheshe bokudlulisa i-fiber optical, obuye benza ubuchwepheshe be-laser welding bukhuthazwe futhi busetshenziswe kabanzi.

7. I-laser beam kulula ukuhlukanisa ngesikhathi nendawo, futhi imishayo eminingi ingacutshungulwa ezindaweni eziningi ngesikhathi esisodwa, inikeze izimo zokushisela okunembe kakhudlwana.

Isici:

1. Ukunemba komhlangano we-workpiece kuyadingeka ukuba kube phezulu, futhi isikhundla se-beam ku-workpiece asikwazi ukuphambuka kakhulu. Lokhu kungenxa yokuthi usayizi wendawo ye-laser ngemuva kokugxila mncane futhi umthungo we-weld mncane, okwenza kube nzima ukwengeza izinto zensimbi zokugcwalisa. Uma ukunemba komhlangano we-workpiece noma ukunemba kokuma kwe-beam kungahlangabezani nezidingo, ukukhubazeka kwe-welding kujwayele ukwenzeka.

2. Izindleko zamalaser nezinhlelo ezihambisanayo ziphezulu, futhi ukutshalwa kwezimali kwesikhathi esisodwa kukhulu.

Ukukhubazeka okujwayelekile kwe-laser weldingekukhiqizeni ibhethri ye-lithium

1. I-Welding porosity

Amaphutha ajwayelekile kulaser weldingkukhona izimbotshana. Ichibi lokushisela elincibilikisiwe lijulile futhi lincane. Phakathi nenqubo yokushisela nge-laser, i-nitrogen ingena echibini elincibilikisiwe ngaphandle. Ngesikhathi sokupholisa nokuqiniswa kwensimbi, ukuncibilika kwe-nitrogen kuyehla ngokuncipha kwezinga lokushisa. Lapho insimbi yechibi elincibilikisiwe iphola ukuze iqale ukucwebezela, ukuncibilika kuzokwehla kakhulu futhi kungazelelwe. Ngalesi sikhathi, inani elikhulu legesi lizokhuphuka libe amabhamuza. Uma ijubane elintantayo lamabhamuza lingaphansi kwejubane le-crystallization yensimbi, kuzokwenziwa ama-pores.

Kuzinhlelo zokusebenza embonini yebhethri ye-lithium, sivame ukuthola ukuthi ama-pores angenzeka ikakhulukazi ngesikhathi sokushiselwa kwe-electrode enhle, kodwa akuvamile ukwenzeka ngesikhathi sokushisela i-electrode engalungile. Lokhu kungenxa yokuthi i-electrode enhle yenziwe nge-aluminium futhi i-electrode engalungile yenziwe ngethusi. Ngesikhathi sokushisela, i-aluminium ewuketshezi engaphezulu iye yaqina ngaphambi kokuba igesi yangaphakathi igcwale ngokuphelele, ivimbele igesi ukuthi ingachichima futhi yakhe izimbobo ezinkulu nezincane. I-stomata encane.

Ngaphandle kwezimbangela zama-pores okukhulunywe ngenhla, ama-pores ahlanganisa nomoya wangaphandle, umswakama, amafutha angaphezulu, njll. Ngaphezu kwalokho, isiqondiso kanye ne-angle yokushaywa kwe-nitrogen kuzophinde kuthinte ukwakheka kwama-pores.

Ngokuqondene nendlela yokunciphisa ukuvela kwe-welding pores?

Okokuqala, ngaphambiliukushisela, amabala amafutha kanye nokungcola ebusweni bezinto ezingenayo kudingeka kuhlanzwe ngesikhathi; ekukhiqizeni amabhethri e-lithium, ukuhlolwa kwezinto ezingenayo kuyinqubo ebalulekile.

Okwesibili, ukugeleza kwegesi evikelayo kufanele kulungiswe ngokuya ngezinto ezifana nesivinini sokushisela, amandla, isikhundla, njll., futhi akufanele kube kukhulu kakhulu noma kuncane kakhulu. Ukucindezela kwengubo evikelayo kufanele kulungiswe ngokuya ngezinto ezifana namandla e-laser nendawo yokugxila, futhi akufanele kube phezulu kakhulu noma kube phansi kakhulu. Ukuma kwe-nozzle yengubo yokuzivikela kufanele kulungiswe ngokuvumelana nokuma, isiqondiso kanye nezinye izici ze-weld ukuze ingubo yokuzivikela ingakwazi ukumboza ngokulinganayo indawo yokushisela.

Okwesithathu, lawula izinga lokushisa, umswakama kanye nothuli olusemoyeni endaweni yokusebenzela. Izinga lokushisa elizungezile kanye nomswakama kuzothinta okuqukethwe komswakama okungaphezulu kwe-substrate kanye negesi yokuvikela, okuzophinde kube nomthelela ekukhiqizeni nasekuphumeni komhwamuko wamanzi echibini elincibilikisiwe. Uma izinga lokushisa elizungezile kanye nomswakama kuphezulu kakhulu, kuzoba nomswakama omningi ebusweni be-substrate kanye negesi yokuzivikela, okukhiqiza inani elikhulu lomhwamuko wamanzi, okuholela kuma-pores. Uma izinga lokushisa elizungezile kanye nomswakama kuphansi kakhulu, kuyoba nomswakama omncane kakhulu ebusweni be-substrate kanye negesi evikelayo, ukunciphisa ukukhiqizwa komphunga wamanzi, ngaleyo ndlela kunciphise ama-pores; vumela abasebenzi bekhwalithi bathole inani eliqondiwe lokushisa, umswakama kanye nothuli esiteshini sokushisela.

Okwesine, indlela ye-beam swing isetshenziselwa ukunciphisa noma ukuqeda ama-pores ku-laser deep penetration welding. Ngenxa yokwengezwa kokujikijela ngesikhathi sokushisela, ukujikijela okuphindaphindayo kwe-beam kumthungo we-weld kubangela ukuphindaphinda kwengxenye ye-weld seam, okwandisa isikhathi sokuhlala kwensimbi ewuketshezi echibini lokushisela. Ngesikhathi esifanayo, ukuphambuka kwe-beam kwandisa nokufakwa kokushisa endaweni ngayinye yeyunithi. I-deep-to-width ratio ye-weld iyancishiswa, okuvumela ukuvela kwama-bubbles, ngaleyo ndlela kuqedwe ama-pores. Ngakolunye uhlangothi, ukushwibeka kwe-beam kubangela imbobo encane ukuthi inyakaze ngokufanele, okungase futhi kunikeze amandla ashukumisayo echibini lokushisela, kwandise i-convection kanye nokunyakaziswa kwe-welding pool, futhi kube nomphumela onenzuzo ekuqedeni ama-pores.

Okwesihlanu, i-pulse frequency, i-pulse frequency ibhekisela enanini lama-pulses akhishwa ugongolo lwe-laser ngesikhathi seyunithi, okuzothinta okokufaka kokushisa kanye nokuqoqwa kokushisa echibini elincibilikisiwe, bese kuthinta inkambu yokushisa kanye nenkundla yokugeleza endaweni encibilikisiwe. ichibi. Uma i-pulse frequency iphezulu kakhulu, izoholela ekufakweni kokushisa okudlulele echibini elincibilikisiwe, okwenza izinga lokushisa lechibi elincibilikisiwe libe phezulu kakhulu, likhiqize umhwamuko wensimbi noma ezinye izakhi eziguquguqukayo kumazinga okushisa aphezulu, okuholela ezimbotsheni. Uma i-pulse frequency iphansi kakhulu, izoholela ekuqongeleleni ukushisa okunganele echibini elincibilikisiwe, okubangela izinga lokushisa lechibi elincibilikisiwe libe liphansi kakhulu, linciphise ukuhlakazeka nokuphuma kwegesi, okuholela ezimbotsheni. Ngokuvamile, imvamisa yokushaya kwenhliziyo kufanele ikhethwe ngaphakathi kwebanga elifanele ngokusekelwe kugqinsi le-substrate namandla e-laser, futhi igweme ukuba phezulu kakhulu noma phansi kakhulu.

Izimbobo zokushisela (i-laser welding)

2. I-Weld spatter

I-spatter ekhiqizwa phakathi nenqubo yokushisela, i-laser welding izothinta kakhulu ikhwalithi yendawo yokushisela, futhi izongcolisa futhi yonakalise ilensi. Ukusebenza okujwayelekile kungokulandelayo: ngemuva kokuqedwa kwe-laser welding, izinhlayiya eziningi zensimbi zivela ebusweni bezinto ezibonakalayo noma umsebenzi futhi zinamathele ebusweni bezinto ezibonakalayo noma umsebenzi. Ukusebenza okunembile kakhulu ukuthi lapho i-welding imodi ye-galvanometer, ngemva kwesikhathi sokusetshenziswa kwelensi evikelayo ye-galvanometer, kuzoba nemigodi eminyene phezulu, futhi le migodi ibangelwa i-welding spatter. Ngemva kwesikhathi eside, kulula ukuvimba ukukhanya, futhi kuyoba nezinkinga ngokukhanya kwe-welding, okuholela ochungechungeni lwezinkinga ezifana ne-welding ephukile kanye ne-welding virtual.

Ziyini izimbangela zokuchaphaza?

Okokuqala, ukuminyana kwamandla, ukuminyana kwamandla okukhulu, kuba lula ukukhiqiza i-spatter, futhi i-spatter ihlobene ngokuqondile nokuminyana kwamandla. Lena inkinga yekhulunyaka. Okungenani kuze kube manje, imboni ayikwazanga ukuxazulula inkinga yokuqhuma, futhi ingasho nje ukuthi incishiswe kancane. Embonini yebhethri ye-lithium, i-splashing iyimbangela enkulu ye-short circuit yebhethri, kodwa ayikwazanga ukuxazulula imbangela. Umthelela we-spatter kubhethri ungancishiswa kuphela ngokombono wokuvikela. Isibonelo, indilinga yezimbobo zokususa uthuli namakhava okuvikela kwengezwa eduze kwengxenye yokushisela, futhi imigqa yemimese yomoya iyengezwa kwimibuthano ukuze kuvinjelwe umthelela we-spatter noma ngisho nokulimala kwebhethri. Ukucekela phansi imvelo, imikhiqizo kanye nezingxenye ezizungeze isiteshi sokushisela kungashiwo ukuthi kuqede izindlela.

Ngokuqondene nokuxazulula inkinga ye-spatter, kungashiwo ukuthi ukunciphisa amandla okushisela kusiza ukunciphisa i-spatter. Ukunciphisa isivinini sokushisela kungasiza futhi uma ukungena kunganele. Kodwa kwezinye izidingo zenqubo ekhethekile, inomphumela omncane. Kuyinqubo efanayo, imishini ehlukene kanye namaqoqo ahlukene wezinto anemiphumela ehluke ngokuphelele yokushisela. Ngakho-ke, kunomthetho ongabhalwanga embonini entsha yamandla, isethi eyodwa yemingcele yokushisela ucezu olulodwa lwemishini.

Okwesibili, uma ingaphezulu lempahla ecutshunguliwe noma i-workpiece ingahlanzwa, amabala kawoyela noma izinto ezingcolisayo nazo zizodala ukuchaphazeka okukhulu. Ngalesi sikhathi, into elula ukuhlanza ubuso bezinto ezicutshungulwayo.

3. Ukubonakala okuphezulu kwe-laser welding

Ngokuvamile, ukuboniswa okuphezulu kubhekisela eqinisweni lokuthi okokusebenza kunokumelana okuncane, indawo ebushelelezi, kanye nezinga eliphansi lokumunca lama-laser aseduze ne-infrared, okuholela ekukhishweni okukhulu kwe-laser, futhi ngenxa yokuthi kusetshenziswa ama-lasers amaningi. ime mpo Ngenxa yempahla noma inani elincane lokuthambekela, ukukhanya kwe-laser ebuyayo kungena kabusha ekhanda eliphumayo, futhi ngisho nengxenye yokukhanya okubuyayo ihlanganiswe nefayibha edlulisa amandla, futhi idluliselwe emuva eduze nefayibha iye ngaphakathi. we-laser, okwenza izingxenye eziyinhloko ngaphakathi kwe-laser ziqhubeke nokuba izinga lokushisa eliphezulu.

Lapho i-reflection iphezulu kakhulu ngesikhathi sokushiswa kwe-laser, kungathathwa izixazululo ezilandelayo:

3.1 Sebenzisa i-anti-reflection coating noma uphathe ingaphezulu lezinto ezibonakalayo: ukumboza ingaphezulu lempahla yokushisela nge-anti-reflection coating kunganciphisa ngempumelelo ukubukeka kwe-laser. Lokhu kunamathela kuvame ukuba yinto ekhethekile yokubona enokukhanya okuphansi okumunca amandla e-laser esikhundleni sokuwabuyisela emuva. Kwezinye izinqubo, ezifana nokushisela umqoqi wamanje, uxhumano oluthambile, njll., indawo engaphezulu nayo ingaqoshwa.

3.2 Lungisa i-angle yokushisela: Ngokulungisa i-angle yokushisela, i-laser beam ingaba isigameko ezintweni zokushisela nge-engeli efanelekile futhi inciphise ukuvela kokubonisa. Imvamisa, ukuba nesigameko se-laser beam perpendicularly to the surface of the material to welded kuyindlela enhle yokunciphisa ukubonakaliswa.

I-3.3 Ukwengeza i-absorbent eyi-axiliary: Ngesikhathi senqubo yokushisela, inani elithile le-absorbent elisizayo, njenge-powder noma i-liquid, lifakwa ku-weld. Lawa ma-absorber amunca amandla e-laser futhi anciphise ukubukeka. I-absorbent efanelekile idinga ukukhethwa ngokusekelwe ezintweni ezithile zokushisela kanye nezimo zokufaka isicelo. Embonini yebhethri ye-lithium, lokhu akunakwenzeka.

3.4 Sebenzisa i-fiber optical ukudlulisa i-laser: Uma kungenzeka, i-fiber optical ingasetshenziswa ukudlulisa i-laser endaweni yokushisela ukuze kuncishiswe ukubonakala. Imicu ye-Optical ingaqondisa i-laser beam endaweni yokushisela ukugwema ukuchayeka okuqondile ebusweni bezinto zokushisela futhi kunciphise ukuvela kokubonisa.

3.5 Ukulungisa amapharamitha we-laser: Ngokulungisa amapharamitha anjengamandla e-laser, ubude be-focal, nobubanzi be-focal, ukusatshalaliswa kwamandla e-laser kungalawulwa futhi ukuboniswa kungancishiswa. Kwezinye izinto ezikhanyayo, ukunciphisa amandla e-laser kungase kube indlela ephumelelayo yokunciphisa ukubonakaliswa.

3.6 Sebenzisa i-beam splitter: I-beam splitter ingaqondisa ingxenye yamandla e-laser kudivayisi yokumuncwa, ngaleyo ndlela yehlise ukuvela kokubonakala. Amadivayisi okuhlukanisa i-Beam ngokuvamile ahlanganisa izingxenye ze-optical nama-absorber, futhi ngokukhetha izingxenye ezifanele nokulungisa ukwakheka kwedivayisi, ukubukeka okuphansi kungafinyelelwa.

4. Welding undercut

Enqubweni yokukhiqiza ibhethri ye-lithium, yiziphi izinqubo ezingase zibangele ukusika phansi? Kungani kwenzeka i-undercutting? Ake siyihlaziye.

I-Undercut, imvamisa izinto zokusetshenziswa zokushisela azihlangani kahle, igebe likhulu kakhulu noma kuvela umsele, ukujula nobubanzi kungaphezulu kuka-0.5mm, ubude obuphelele bukhulu kuno-10% wobude bokushisela, noma bukhulu kunesilinganiso senqubo yomkhiqizo ubude obuceliwe.

Kuyo yonke inqubo yokukhiqiza ibhethri ye-lithium, ukusika phansi kungenzeka kakhulu, futhi ngokuvamile kusatshalaliswa ekubekeni uphawu ngaphambi kokushisela kanye nokushisela ipuleti lekhava eliyicylindrical kanye nokubekwa uphawu kwangaphambi kokushisela kanye nokushisela kwepuleti lekhava le-aluminium yesikwele. Isizathu esiyinhloko ukuthi ipuleti lekhava lokuvala lidinga ukusebenzisana negobolondo ku-Welding, inqubo yokufanisa phakathi kwepuleti lekhava lokuvala futhi igobolondo lithambekele ekubeni nezikhala zokushisela ngokweqile, ama-grooves, ukuwa, njll., ngakho-ke ijwayele ukunqamuka .

Ngakho-ke yini ebangela i-undercutting?

Uma ijubane lokushisela lishesha kakhulu, insimbi ewuketshezi ngemuva kwembobo encane ekhomba enkabeni yokushisela ngeke ibe naso isikhathi sokusabalalisa kabusha, okuholela ekuqinisweni nasekungeneni ngaphansi kwezinhlangothi zombili ze-weld. Ngenxa yalesi simo esingenhla, sidinga ukwandisa amapharamitha we-welding. Ukukubeka kalula, kuwukuhlolwa okuphindaphindiwe ukuze uqinisekise amapharamitha ahlukahlukene, futhi uqhubeke wenza i-DOE kuze kutholakale imingcele efanele.

2. Izikhala zokushisela ngokweqile, ama-grooves, ukuwa, njll. kwezinto zokushisela kuzonciphisa inani lensimbi encibilikisiwe egcwalisa izikhala, okwenza ama-undercuts angenzeka kakhulu. Lona umbuzo wemishini nezinto zokusetshenziswa. Ukuthi izinto ezisetshenziswayo zokushisela ziyahlangabezana yini nezidingo zempahla engenayo yenqubo yethu, noma ngabe ukunemba kwemishini kuyahlangabezana yini nezidingo, njll. Umkhuba ojwayelekile uwukuhlukumeza njalo nokushaya abahlinzeki kanye nabantu abaphethe impahla.

3. Uma amandla ehla ngokushesha kakhulu ekupheleni kwe-laser welding, imbobo encane ingase iwe, okuholela ekusithekeni kwendawo. Ukumatanisa okulungile kwamandla nesivinini kungavimbela ngempumelelo ukwakheka kwama-undercuts. Njengoba isisho sakudala sisho, phinda izivivinyo, qinisekisa amapharamitha ahlukahlukene, bese uqhubeke okuthi DOE uze uthole amapharamitha alungile.

5. Ukuwa kwesikhungo sokushisela

Uma ijubane lokushisela lihamba kancane, ichibi elincibilikisiwe lizoba likhulu futhi libe banzi, likhulise inani lensimbi encibilikisiwe. Lokhu kungenza ukugcina ukungezwani kwendawo kube nzima. Lapho insimbi encibilikisiwe isinda kakhulu, isikhungo se-weld singacwila futhi senze amadiphu nemigodi. Kulokhu, ukuminyana kwamandla kumele kwehliswe ngendlela efanele ukuze kuvinjwe ukuwa kwechibi elincibilikayo.

Kwesinye isimo, igebe lokushisela livele lakha ukuwohloka ngaphandle kokubangela ukubhobozwa. Lokhu akungabazeki ukuthi kuyinkinga yokulingana kwemishini.

Ukuqonda kahle ukukhubazeka okungenzeka ngesikhathi sokushisela nge-laser kanye nezimbangela zokukhubazeka okuhlukene kuvumela indlela eqondiswe kakhulu yokuxazulula noma yiziphi izinkinga ezingavamile zokushisela.

6. Imifantu yokushisela

Imifantu evela ngesikhathi sokushisela nge-laser ngokuyinhloko imifantu eshisayo, njengokuqhekeka kwekristalu nokuqhekeka kwe-liquefaction. Isizathu esiyinhloko salokhu kuqhekeka amandla amakhulu okuncipha akhiqizwa i-weld ngaphambi kokuba iqine ngokuphelele.

Kukhona nezizathu ezilandelayo zokuqhekeka kwe-laser welding:

1. Umklamo we-weld ongenangqondo: Ukuklama okungalungile kwejometri nobukhulu be-weld kungase kubangele ukugxilwa kokucindezeleka kwe-welding, ngaleyo ndlela kubangele imifantu. Isixazululo ukukhulisa idizayini yokushisela ukugwema ukugxilwa kwengcindezi yokushisela. Ungasebenzisa ama-weld weld afanelekile, ushintshe umumo we-weld, njll.

2. Ukungafani kwemingcele ye-welding: Ukukhetha okungalungile kwemingcele ye-welding, njengesivinini sokushisela esisheshayo, amandla aphezulu kakhulu, njll., kungase kuholele ekushintsheni kwezinga lokushisa elingalingani endaweni ye-welding, okuholela ekucindezelekeni okukhulu kwe-welding kanye nokuqhekeka. Isixazululo ukulungisa amapharamitha wokushisela ukuze afane nezinto ezithile kanye nezimo zokushisela.

3. Ukulungiswa okungalungile kwendawo yokushisela: Ukwehluleka ukuhlanza kahle nokuphatha ngaphambili indawo yokushisela ngaphambi kokushisela, njengokususa ama-oxide, amafutha, njll., kuzothinta ikhwalithi namandla we-weld futhi kuholele kalula emifantwini. Isixazululo siwukuhlanza ngokwanele futhi uphathe ngaphambili indawo yokushisela ukuze kuqinisekiswe ukuthi ukungcola nokungcola endaweni ye-welding kuyaphathwa ngokuphumelelayo.

4. Ukulawulwa okungalungile kokufaka ukushisa kwe-welding: Ukulawulwa okungalungile kokufaka ukushisa ngesikhathi sokushisela, njengokushisa ngokweqile ngesikhathi sokushisela, izinga lokupholisa elingafanele le-welding layer, njll., kuzoholela ekushintsheni kwesakhiwo sendawo yokushisela, okuholela ekuqhekekeni. . Isixazululo ukulawula izinga lokushisa kanye nezinga lokupholisa ngesikhathi sokushisela ukugwema ukushisa ngokweqile nokupholisa ngokushesha.

5. Ukunciphisa ukucindezeleka okwanele: Ukwelashwa okwanele kokunciphisa ukucindezeleka ngemva kokushisela kuzoholela ekunciphiseni ukucindezeleka okwanele endaweni ehlanganisiwe, okuzoholela kalula ekuqhekekeni. Isixazululo ukwenza ukwelashwa okufanele kokunciphisa ukucindezeleka ngemva kokushisela, njengokwelashwa kokushisa noma ukwelashwa kokudlidliza (isizathu esiyinhloko).

Ngokuqondene nenqubo yokukhiqiza amabhethri e-lithium, yiziphi izinqubo ezingase zibangele imifantu?

Ngokuvamile, imifantu ijwayele ukwenzeka ngesikhathi sokubeka uphawu, njengokubeka uphawu kwamagobolondo ensimbi ayi-cylindrical noma amagobolondo e-aluminium, ukufaka uphawu kwamagobolondo e-aluminium esikwele, njll. Ngaphezu kwalokho, ngesikhathi senqubo yokupakisha imojula, ukushiselwa komqoqi wamanje nakho kuthambekele. ukuqhekeka.

Yiqiniso, singasebenzisa futhi i-filler wire, preheating noma ezinye izindlela zokunciphisa noma ukuqeda le mifantu.

Isikhathi sokuthumela: Sep-01-2023