Njengomphathi wezinye izingxenye zemoto, ubuchwepheshe bokukhiqiza bomzimba wemoto bunquma ngokuqondile ikhwalithi yokukhiqiza yemoto. Enqubweni yokukhiqiza umzimba wezimoto, ukushisela kuyinqubo ebalulekile yokukhiqiza. Ubuchwepheshe bokushisela okwamanje obusetshenziselwa ukushisela umzimba we-auto ikakhulukazi buhlanganisa ukushisela indawo yokumelana, ukushisela kwegesi encibilikisiwe encibilikisiwe (i-MIG welding) kanye ne-molten active gas shielded arc welding (MAG welding) kanye ne-laser welding.

Njengobuchwepheshe bokushisela obuthuthukisiwe obunokuhlanganiswa kwe-optical-mechanical, ubuchwepheshe be-laser welding bunobuhle bokuminyana kwamandla aphezulu, isivinini sokushisela esisheshayo, ingcindezi yokushisela ephansi kanye nokuguqulwa, kanye nokuguquguquka okuhle uma kuqhathaniswa nobuchwepheshe bendabuko bokushisela umzimba.

Isakhiwo somzimba wemoto siyinkimbinkimbi, futhi izingxenye zomzimba ikakhulukazi ziyizingxenye ezinodonga oluncane futhi ezigobile. I-auto body welding ibhekene nobunzima bokushisela njengokuhlukahluka kwezinto zokwakha zomzimba, ukujiya okuhlukahlukene kwezingxenye zomzimba, ama-trajectories e-welding ahlukahlukene kanye namafomu ahlangene. Ngaphezu kwalokho, ukushisela umzimba wezimoto kunezidingo eziphezulu zekhwalithi yokushisela nokusebenza kahle kwe-welding.

Ngokusekelwe kumapharamitha wenqubo yokushisela afanelekile, i-laser welding ingaqinisekisa amandla aphezulu okukhathala kanye nokuqina komthelela wezingxenye ezibalulekile zomzimba we-auto lapho kushiselwa, ngaleyo ndlela kuqinisekiswe ikhwalithi nempilo yesevisi yokushisela umzimba. Ubuchwepheshe bokushisela nge-laser bungajwayela ukushiselwa kwezingxenye zomzimba ezizenzakalelayo ezinamafomu ahlukene ahlangene, ubukhulu obuhlukahlukene kanye nezinhlobo zezinto ezibonakalayo, ukuhlangabezana nesidingo sokuguquguquka ekukhiqizeni umzimba wezimoto. Ngakho-ke, ubuchwepheshe be-laser welding buyindlela yobuchwepheshe ebalulekile yokufeza ukuthuthukiswa kwekhwalithi ephezulu yemboni yezimoto.

Inqubo yokushisela i-laser yemizimba yezimoto

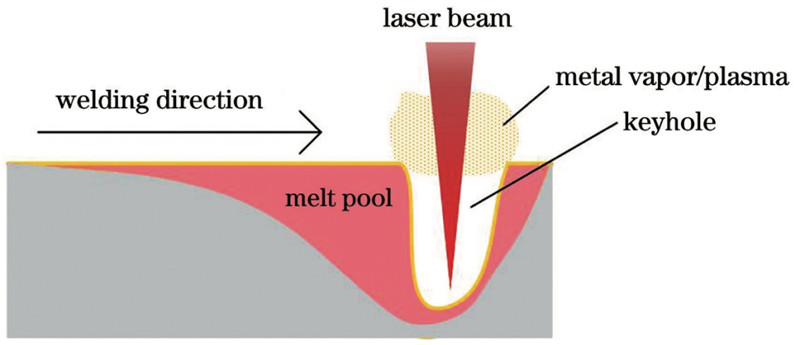

Isimiso senqubo yokushisela i-laser deep fusion: Lapho ukuminyana kwamandla e-laser kufinyelela ezingeni elithile, indawo ebonakalayo iyahwamuka, ngaleyo ndlela yakhe imbobo kakhiye. Lapho ukucindezela komhwamuko wensimbi ngaphakathi kwembobo kufinyelela ekulinganeni okuguquguqukayo nokucindezela okumile kanye nokushuba kwesimo samanzi oketshezi oluzungezile, i-laser ingakhipha imisebe ngembobo kakhiye iye phansi embobeni, futhi ngokuhamba kwe-laser beam, i-weld eqhubekayo kwakheka. Enqubweni yokushisela i-laser deep fusion, asikho isidingo sokwengeza i-auxiliary flux noma isigcwalisi ukuze ushisele izinto zocwecwe lokusebenza zibe yinto eyodwa.

Umthungo we-weld otholwe yi-laser deep fusion welding ngokuvamile ubushelelezi futhi uqondile nge-deformation encane, esiza ekuthuthukiseni ukunemba kokukhiqiza komzimba we-auto. Amandla aqinile we-weld aphezulu, okuqinisekisa ikhwalithi yokushisela yomzimba we-auto. Ijubane lokushisela liyashesha, elisiza ekuthuthukiseni ukusebenza kahle kokukhiqizwa kwe-welding.

Enqubweni yokushisela umzimba we-auto, ukusetshenziswa kwenqubo ye-laser deep fusion welding kunganciphisa kakhulu inani lezingxenye, isikhunta kanye ne-welding tooling, ngaleyo ndlela kunciphise isisindo esifile somzimba nezindleko zokukhiqiza. Kodwa-ke, inqubo yokushisela i-laser deep fusion ayibekezeleli igebe lomhlangano lezingxenye ezishiselwe, futhi igebe lomhlangano lidinga ukulawulwa phakathi kuka-0.05 no-2 mm. Uma igebe lomhlangano likhulu kakhulu, kuzovela iziphambeko zokushisela njenge-porosity.

Ucwaningo lwamanje lubonisa ukuthi ku-auto body welding yento efanayo, ngokuthuthukisa imingcele yenqubo ye-laser deep-fusion welding, kungenzeka ukuthola i-weld enokwakheka okuhle kwendawo, ukukhubazeka okumbalwa kwangaphakathi kanye nezakhiwo ezinhle kakhulu zemishini. Izakhiwo ezinhle kakhulu zemishini ye-weld zingahlangabezana nezidingo zokusetshenziswa zezingxenye ezishiselwe umzimba we-auto. Kodwa-ke, ku-auto body welding, i-aluminium alloy-steel njengommeleli we-heterogeneous metal laser deep fusion welding process ayivuthiwe, nakuba ngokungeza ungqimba olushintshayo ingathola ukusebenza okuhle kakhulu kwe-weld, kodwa izinto ezihlukene zoguquko lwesendlalelo I-IMC layer ithonya indlela futhi umphumela wayo esakhiweni esincane se-weld mechanism awucacile, udinga olunye ucwaningo olujulile.

I-Auto Body Laser Wire Filling Welding Process

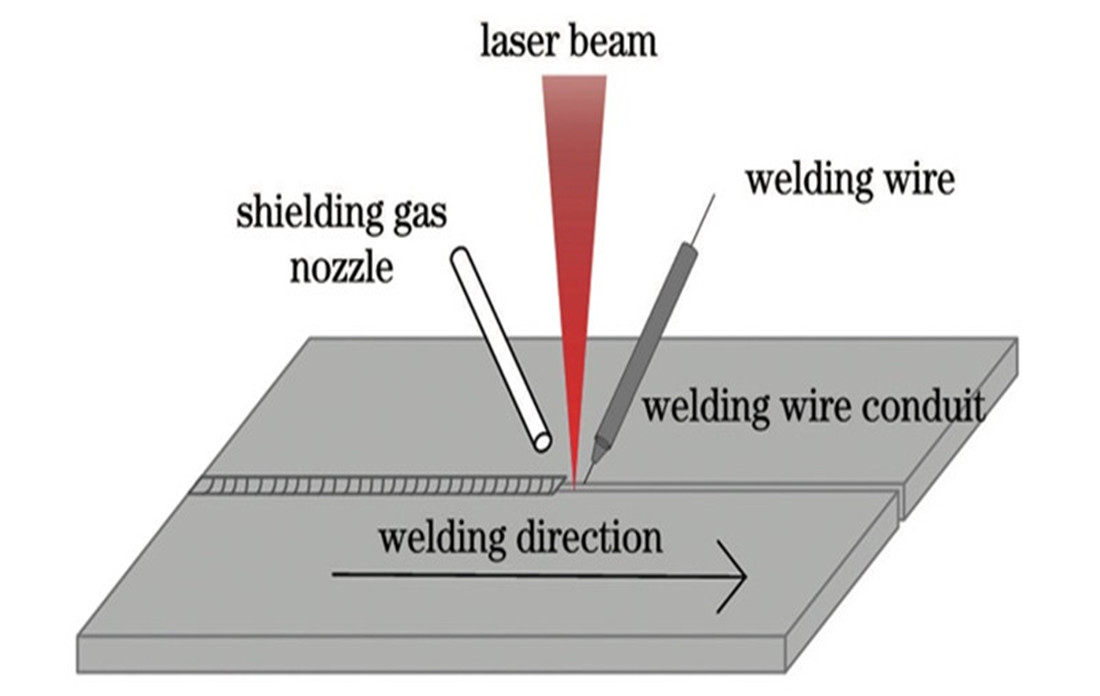

Inqubo yokushisela i-laser filler isekelwe kulesi simiso esilandelayo: Ijoyinti elishiselwe lakhiwa ngokugcwalisa ngaphambili i-weld ngocingo oluthile noma ngokuphakela ucingo ngesikhathi esisodwa ngesikhathi senqubo ye-laser welding. Lokhu kulingana nokuphakela inani elicishe lilingane lezinto zocingo echibini lokushisela ngesikhathi sokushisela nge-laser deep fusion. Umdwebo ongezansi ubonisa inqubo yokushisela i-laser filler.

Uma kuqhathaniswa ne-laser deep fusion welding, i-laser filler welding inezinzuzo ezimbili ku-auto body welding: okokuqala, ingathuthukisa kakhulu ukubekezelelana kwegebe lomhlangano phakathi kwezingxenye zomzimba ezizenzakalelayo ukuze zishiseliswe futhi kuxazululwe inkinga yesidingo segebe esiphezulu se-laser deep fusion welding. ; okwesibili, ingathuthukisa ukusatshalaliswa kwezicubu endaweni yokushisela ngokusebenzisa izintambo ezinokuqukethwe okuhlukile kokubunjwa, bese ilawula ukusebenza kwe-weld.

Enqubweni yokukhiqiza umzimba wezimoto, inqubo yokushisela i-laser filler isetshenziswa kakhulu ukushisela i-aluminium alloy nezingxenye zensimbi zomzimba. Ikakhulukazi enqubweni yokushisela izingxenye ze-aluminium alloy yomzimba we-auto, ukungezwani okungaphezulu kwechibi elincibilikisiwe kuncane, okungaholela kalula ekuweni kwechibi elincibilikisiwe, kuyilapho inqubo yokushisela i-laser filler ingaxazulula kangcono inkinga yokuwa kwechibi elincibilikisiwe. ngokuncibilika kocingo ohlelweni lwe-laser welding.

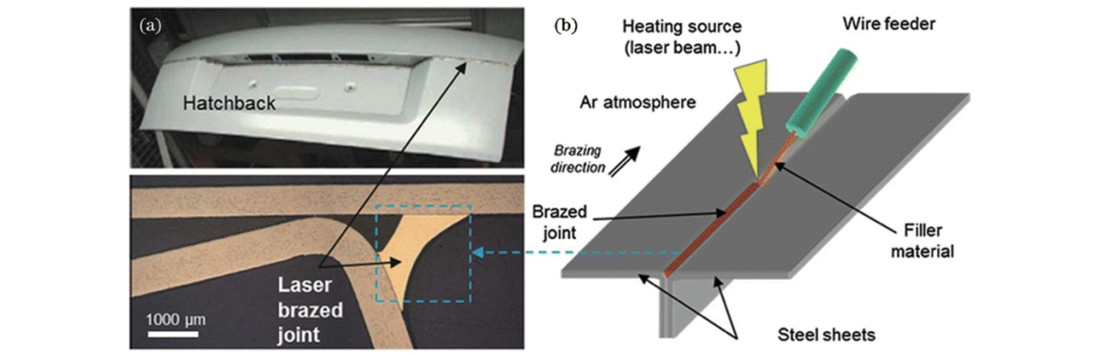

Inqubo ye-automotive body laser brazing

Inqubo ye-laser brazing isekelwe kulesi simiso esilandelayo: Ukusebenzisa i-laser njengomthombo wokushisa, i-laser beam igxilile futhi ifakwe imisebe phezu kocingo, intambo iyancibilika, intambo encibilikisiwe idonsela phansi futhi igcwalise ucezu lokusebenza ukuze lushiselwe, kanye nemiphumela ye-metallurgical efana nokuncibilika nokusabalalisa kwenzeka phakathi kwezinto zokubrawuza kanye nendawo yokusebenza, ngaleyo ndlela kuhlanganisa ucezu lokusebenza. Ngokungafani nenqubo yokushisela i-laser filler, inqubo ye-laser brazing incibilikisa intambo kuphela hhayi into yokusebenza okufanele ishiselwe. I-laser brazing inokuqina okuhle kwe-welding, kodwa amandla aqinile we-weld ewumphumela aphansi. Umfanekiso wesi-3 ubonisa ukusetshenziswa kwenqubo ye-laser brazing ekushiseleni ikhava yegumbi lomthwalo wezimoto

Enqubweni yokushisela umzimba ngokuzenzakalelayo, inqubo ye-laser brazing isetshenziswa ngokuyinhloko ukushisela izingxenye zomzimba ezingadingi amandla aphezulu ahlangene, njengokushisela phakathi kwekhava ephezulu neseceleni okuzungezile, ukushisela phakathi kwengxenye engaphezulu nephansi yomthwalo. ikhava yekhompathimenti, njll. Ikhava ephezulu ye-VW, Audi namanye amamodeli aphakathi nendawo kanye nesezingeni eliphezulu wonke asebenzisa inqubo yokubhula ngelaser.

Amaphutha amakhulu ekuhlanganiseni kwe-laser brazed emizimbeni yezimoto kufaka phakathi ukuququda emaphethelweni, i-porosity, i-weld deformation, njll., futhi ukukhubazeka kungacindezelwa kakhulu ngokulawula amapharamitha wenqubo nokusebenzisa inqubo yokugxila kwe-laser egxile kakhulu.

Inqubo yokushisela eyinhlanganisela ye-laser-arc yomzimba wezimoto

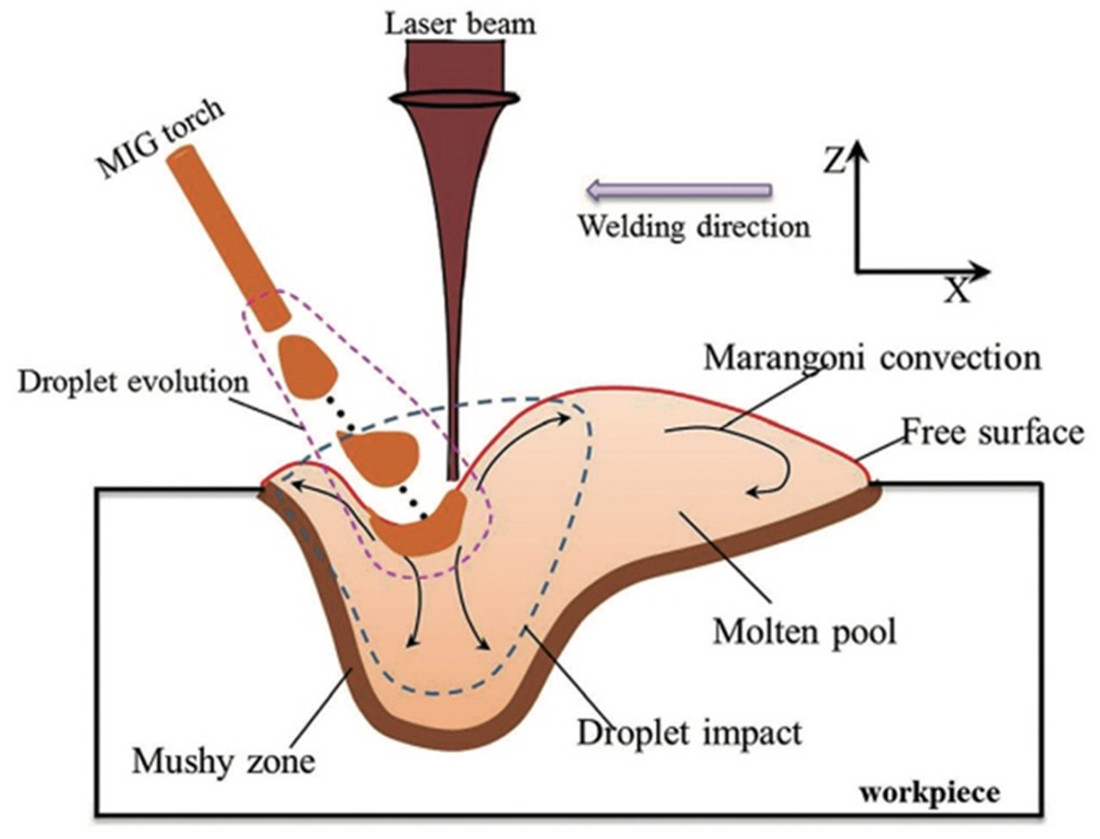

Isimiso se-laser-arc composite inqubo yokushisela imi kanje: imithombo emibili yokushisa, i-laser ne-arc, isetshenziselwa ukusebenza ngesikhathi esisodwa ebusweni bomsebenzi ozoshiselwa, futhi i-workpiece iyancibilika futhi iqiniswe ukuze yenze i-weld seam. Umdwebo ongezansi ubonisa inqubo ye-laser-arc welding.

I-laser-arc composite welding ihlanganisa izinzuzo ze-laser welding kanye ne-arc welding: okokuqala, ngaphansi kwesenzo semithombo yokushisa ekabili, isivinini sokushisela singakhuphuka, okokufaka ukushisa kuba kuncane, i-weld deformation incane, igcina izici ze-laser welding. ; okwesibili, ikhono elingcono lokuvala ibhuloho, ukubekezelelana kwegebe lomhlangano kukhulu; okwesithathu, ijubane lokuqinisa lechibi elincibilikisiwe liba kancane, elivumela ukuqedwa kwama-pores, imifantu kanye nezinye iziphambeko zokushisela, ukuthuthukisa inhlangano nokusebenza kwendawo ethintekile ukushisa Okwesine, ngenxa ye-arc, iyakwazi ukushisela izinto ezibonisa ukukhanya okuphezulu kanye ne-thermal conductivity ephezulu, enohlu olubanzi lwezinto ezisetshenziswayo.

Enqubweni yokukhiqiza umzimba we-auto, inqubo yokushisela i-laser - arc composite welding ikakhulukazi ihlanganisa izingxenye ze-aluminium alloy yomzimba kanye nengxube ye-aluminium - izinsimbi ezihlukene zensimbi, ukuze kube negebe lokuhlanganisa lezingxenye ezinkulu zokushisela, njengengxenye yomnyango wemoto yendawo i-welding, lokhu kungenxa yokuthi igebe lomhlangano livumelana nokusebenza kwebhuloho le-laser - i-arc composite welding. Ngaphezu kwalokho, ubuchwepheshe be-laser-MIG arc composite welding buye busetshenziswe endaweni yophahla oluseceleni lwe-Audi body.

Enqubweni yokushisela umzimba we-auto, i-laser-arc composite welding inenzuzo yokubekezelela igebe elikhulu uma kuqhathaniswa ne-laser welding eyodwa, nokho, i-laser-arc composite welding idinga ukucatshangelwa okuphelele kwesimo esihlobene se-laser ne-arc, imingcele ye-laser welding, i-arc. amapharamitha nezinye izici. Ukuziphatha kokushisa nokudluliswa okukhulu kwenqubo yokushisela i-laser-arc kuyinkimbinkimbi, ikakhulukazi ukulawulwa kwamandla we-heterogeneous material welding kanye nendlela yokuqina kwe-IMC nokulawulwa kwezicubu akukacaci futhi kudinga ukuqiniswa okwengeziwe kocwaningo.

Ezinye izinqubo ze-automotive body laser welding

I-laser deep fusion welding, i-laser filler welding, i-laser brazing kanye ne-laser-arc composite welding nezinye izinqubo zokushisela zinombono ovuthiwe kakhudlwana kanye nezinhlobonhlobo zezinhlelo zokusebenza ezisebenzayo. Njengoba izidingo zemboni yezimoto zokushisela umzimba zikhula kanye nesidingo sokushisela izinto ezingafani ekukhiqizeni izinto ezingasindi sikhula, ukushisela indawo ye-laser, i-laser oscillation welding, i-multi-laser beam welding kanye ne-laser flight welding sekuthole ukunakwa.

Inqubo yokushisela indawo ye-laser

I-laser spot welding ubuchwepheshe bokushisela nge-laser obunezinzuzo ezivelele zejubane lokushisela elisheshayo kanye nokunemba okuphezulu kwe-welding. Umgomo oyisisekelo wokushisela indawo ye-laser ukugxilisa ugongolo lwe-laser endaweni ethile ezoshiselwa, ukuze insimbi ngaleso sikhathi incibilike khona manjalo, futhi ngokulungisa ukuminyana kwe-laser ukuze kuzuzwe ukushiselwa kwe-thermal conduction noma umphumela we-fusion welding ojulile, lapho i-laser beam iyeka ukusebenza, i-reflux yensimbi ewuketshezi, iqine futhi yakhe ilunga.

Kunezinhlobo ezimbili eziyinhloko ze-laser spot welding: i-pulsed laser spot welding kanye ne-continuous laser spot welding. I-laser beam in pulsed laser spot welding inamandla aphezulu aphezulu, kodwa isikhathi sokusebenza sifushane, futhi ngokuvamile sisetshenziselwa ukushisela izinsimbi ezikhanyayo njengama-alloys e-magnesium nama-alloys e-aluminium. Ku-laser spot welding eqhubekayo, i-laser beam inamandla ayisilinganiso esiphezulu nesikhathi eside sesenzo se-laser, futhi isetshenziselwa kakhulu ukushisela insimbi.

Ekushiseleni umzimba okuzenzakalelayo, uma kuqhathaniswa nokushisela indawo yokumelana, i-laser spot welding inezinzuzo zokungathintani nendawo yokushisela indawo eziklanyelwe yona, engahlangabezana nesidingo sokushisela kwekhwalithi ephezulu ngaphansi kwezikhala ezihlukene zamathanga ezinto ezisetshenziswayo zomzimba.

Inqubo yokushisela i-laser oscillation

I-Laser oscillation welding ubuchwepheshe obusha be-laser welding obuhlongozwe eminyakeni yamuva nje futhi sebuthole ukunakwa okusabalele. Umgomo walobu buchwepheshe ukufeza i-oscillation esheshayo, ehlelekile futhi encane ye-laser beam ngokuhlanganisa isibuko se-oscillating ekhanda le-laser welding, ngaleyo ndlela uzuze umphumela wokugqugquzela ugongolo ngenkathi uhamba phambili ngesikhathi se-laser welding.

Izindlela eziyinhloko ze-oscillation kwinqubo ye-laser oscillation welding zihlanganisa: i-oscillation eguquguqukayo, i-longitudinal oscillation, i-oscillation eyindilinga kanye ne-oscillation engapheli. Inqubo yokushisela i-laser oscillation inezinzuzo ezibalulekile ekushiseleni komzimba okuzenzakalelayo, njengoba isimo sokugeleza kwechibi elincibilikayo sishintshwa ngokuphawulekayo yi-oscillation ye-laser beam, ngakho-ke inqubo ingakwazi ukuqeda amaphutha angaxutshiwe, ifinyelele ukucolisiswa okusanhlamvu futhi icindezele i-porosity ekushiseleni impahla efanayo yomzimba wezimoto, futhi kuthuthukiswe izinkinga zokungahlangani okwanele kwezinto ezihlukene kanye nezakhiwo ezingasebenzi kahle zemishini yomthungo we-weld ekushiseleni kwezinto ezihlukene zomzimba ezizenzakalelayo.

Inqubo yokushisela i-Multi-laser beam

Njengamanje, ama-fiber lasers angasetshenziswa ukuhlukanisa i-laser beam eyodwa ibe yimishayo ye-laser eminingi kusetshenziswa imojula yokuhlukanisa i-beam efakwe ekhanda lokushisela. I-Multi-laser beam welding ilingana nokusebenzisa imithombo yokushisa eminingi kunqubo yokushisela. Ngokulungisa ukusatshalaliswa kwamandla kwe-beam, imishayo ehlukene ingafinyelela imisebenzi ehlukene, njengokuthi: i-beam ene-energy density iyisigxobo esiyinhloko, esibhekene ne-deep melt welding; i-sub-beam ene-low density yamandla ingahlanza futhi ishise kuqala indawo ebonakalayo futhi yandise ukumuncwa kwamandla we-laser beam ngento.

Inqubo yokushisela i-laser multi-laser ingathuthukisa ukuziphatha kokuhwamuka komhwamuko we-zinc kanye nokuziphatha okuguquguqukayo kwechibi elincibilikayo ngesikhathi sokushiselwa kwamashidi ensimbi, ithuthukise inkinga yokufafaza futhi ithuthukise amandla okubamba komthungo wokushisela.

Inqubo yokushisela indiza ye-laser

Ubuchwepheshe bokushisela indiza ye-laser ubuchwepheshe obusha be-laser welding obusebenza kahle kakhulu bokushisela kanye nomklamo ozimele we-welding trajectory. Umgomo oyisisekelo wokushisela indiza nge-laser ukuthi uma i-laser beam isenzeka ezibukweni ze-X ne-Y zesibuko esithwebulayo, i-engeli yesibuko ilawulwa ngohlelo oluzimele ukuze kuzuzwe ukuchezuka kwe-laser beam kunoma iyiphi i-engeli.

Ngokwesiko, i-laser welding ye-auto body incike kakhulu kurobhothi lokushisela ukushayela ikhanda le-laser lokushisela ukunyakaza okuvumelanayo ukuze kuzuzwe umphumela wokushisela. Kodwa-ke, ukunyakaza okuphindaphindiwe okuphindaphindayo kwerobhothi lokushisela kunciphisa kakhulu ukusebenza kahle kwe-auto body welding ngenxa yenani elikhulu lama-welds nobude obude bokushisela. Ngokuphambene, i-laser flight welding ingafinyelelwa phakathi kwebanga elithile ngokumane ulungise i-engeli yesibonisi. Ngakho-ke, ubuchwepheshe bokushisela indiza ye-laser bungathuthukisa kakhulu ukusebenza kahle kokushisela futhi bunethuba elibanzi lesicelo.

Isifinyezo

Ngokuthuthuka kwemboni yezimoto, ikusasa lobuchwepheshe bokushisela umzimba lizoqhubeka nokuthuthuka kukho kokubili inqubo yokushisela kanye nobuchwepheshe obuhlakaniphile.

I-Auto body, ikakhulukazi indikimba yemoto yamandla entsha, iyathuthuka ibheke kwesisindo esilula. Ama-alloys angasindi, izinto eziyinhlanganisela nezinto ezixubile zizosetshenziswa kabanzi emzimbeni we-auto, inqubo ye-laser welding evamile inzima ukuhlangabezana nezidingo zayo zokushisela, ngakho-ke inqubo yokushisela ikhwalithi ephezulu kanye nephumelelayo izoba umkhuba wokuthuthukiswa kwesikhathi esizayo.

Eminyakeni yamuva nje, inqubo yokushisela i-laser esafufusayo, efana ne-laser swing welding, i-multi-laser beam welding, i-laser flight welding, njll., ibisezingeni lokushisela nokusebenza kahle kokushisela kocwaningo lokuqala lwethiyori kanye nokuhlola inqubo. Ikusasa lidinga ukuthi kube inqubo yokushisela ye-laser evelayo kanye nezinto ezingasindi zomzimba ezizenzakalelayo, i-heterogeneous materials welding nezinye izimo ezihlanganiswe eduze, i-laser beam swing trajectory design, i-multi-laser beam energy action mechanism kanye nokwenza ngcono ukusebenza kahle kwe-flight welding kanye nezinye izici zoku- ucwaningo olunzulu lokuhlola inqubo yokushisela umzimba we-lightweight ekhulile.

Ubuchwepheshe bokushisela i-laser yomzimba ngokuzenzakalelayo buhlanganiswe ngokujulile nobuchwepheshe obukhaliphile, inzwa yesikhathi sangempela yesimo sokushisela i-laser yomzimba kanye nokulawulwa kwempendulo yamapharamitha wenqubo kunendima ebalulekile kwikhwalithi yokushisela. Ubuchwepheshe bamanje be-laser welding obuhlakaniphile busetshenziselwa kakhulu ukuhlela umzila we-pre-welding kanye nokulandelela kanye nokuhlolwa kwekhwalithi yangemuva kokushisela. Ucwaningo lwasekhaya nolwangaphandle ekutholeni amaphutha okushisela kanye nokulawulwa okuguquguqukayo kwamapharamitha kuseyinsakavukela umchilo wesidwaba, futhi imingcele yenqubo yokushisela nge-laser ubuchwepheshe bokulawula obuvumelanayo abukasetshenziswa ekukhiqizeni umzimba wezimoto.

Ngakho-ke, ukuze kusetshenziswe ubuchwepheshe be-laser welding ku-auto body welding process izici, ikusasa kufanele lithuthukiswe ngesistimu yokuzwa ehlakaniphile ye-multi-sensor core laser welding kanye ne-high-speed high-precision welding welding control system ukuze kuqinisekiswe ukuthi ukushisela kwe-laser. ubuchwepheshe obuhlakaniphile ngesikhathi sangempela kanye nokunemba kwesixhumanisi ngasinye, ngokusebenzisa isixhumanisi "se-welding trajectory plan - imingcele ye-welding adaptive control post-welding quality Ukuhlolwa kwe-inthanethi" isixhumanisi, ukuqinisekisa izinga eliphezulu nokucubungula okuphumelelayo.

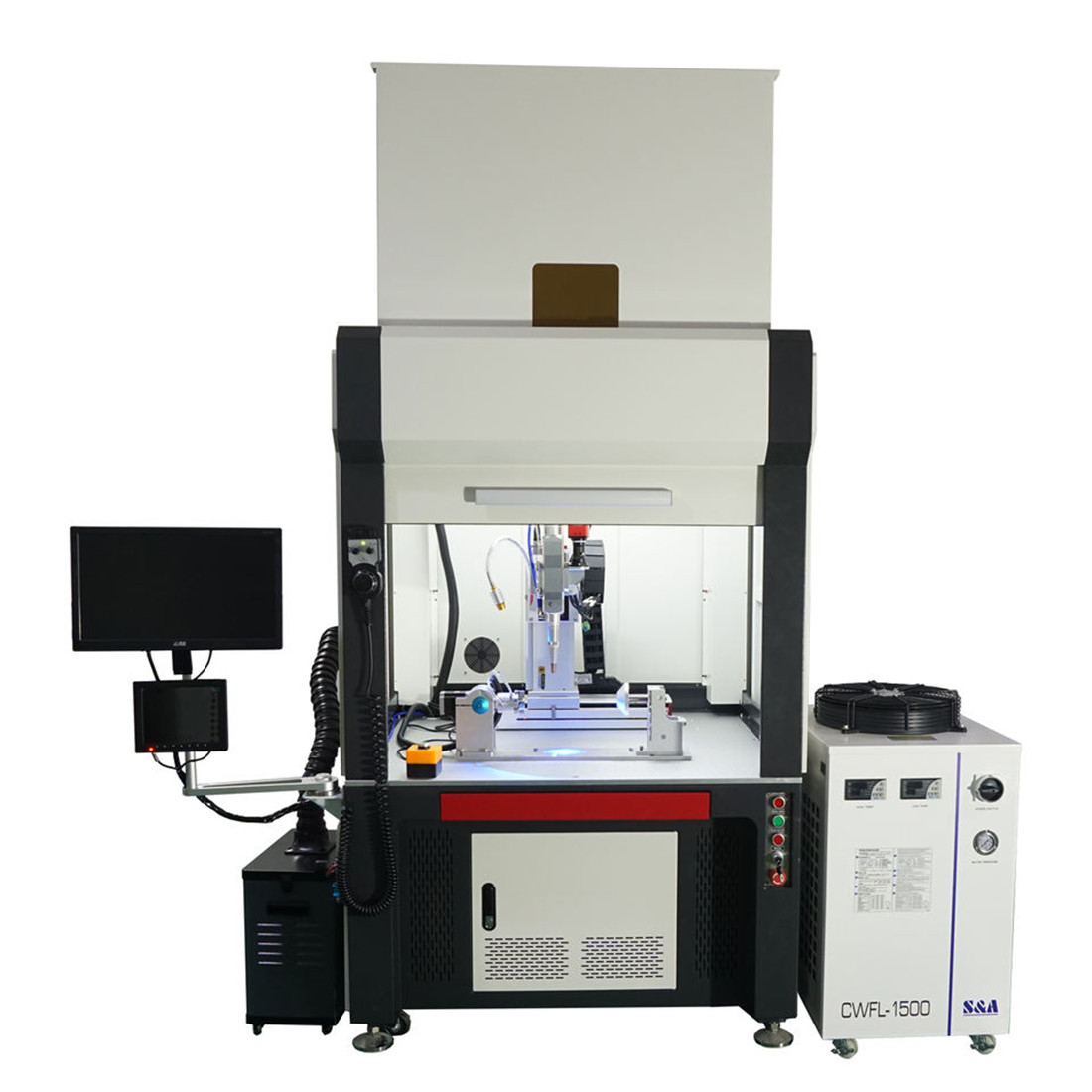

Inkampani ye-Maven laser automation igxile embonini ye-laser iminyaka engu-14, sisebenza ngokukhethekile nge-laser welding, sinomshini wokushisela ingalo we-robotic, umshini we-Table Automatic Laser Welding, umshini wokushisela we-Handheld Laser, ngaphezu kwalokho, sinomshini wokushisela we-laser, umshini wokusika we-laser. kanye nomshini wokuqopha we-laser, sinamacala amaningi esixazululo se-laser welding, uma unentshisekelo ungahlala usithinta.

Isikhathi sokuthumela: Dec-09-2022