Usayizi wobubanzi be-laser core uzothinta ukulahleka kokudlulisela kanye nokusatshalaliswa kokukhanya kwamandla. Ukukhetha okunengqondo kwe-diameter eyinhloko kubaluleke kakhulu. Ububanzi bomgogodla owedlulele buzoholela ekuhlanekeni kwemodi kanye nokusakazeka ekudluliselweni kwe-laser, kuthinte ikhwalithi ye-beam kanye nokunemba kokugxila. I-diameter eyinhloko encane kakhulu izodala Ukulinganisa kwamandla okukhanya kwe-fiber yemodi eyodwa kuba kubi kakhulu, okungahambisani nokudluliswa kwe-i-laser enamandla amakhulu.

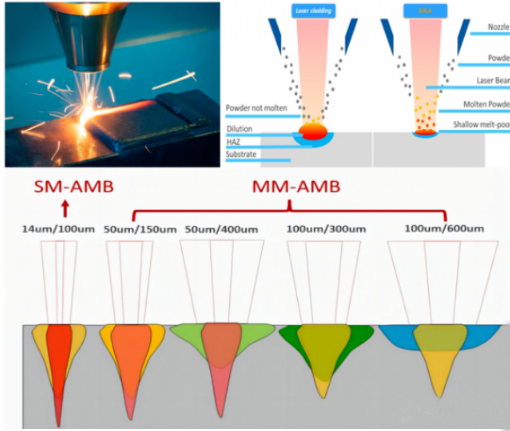

1. Izinzuzo kanye nokusetshenziswa kwama-laser amancane amaphakathi (<100um)

Izinto ezikhanyayo kakhulu: i-aluminium, ithusi, insimbi engagqwali, i-nickel, i-molybdenum, njll.;

(1)Izinto ezibonisa ukukhanya kakhulu zidinga ukukhetha i-laser encane yobubanzi obuphakathi. I-laser density high power beam isetshenziselwa ukushisisa ngokushesha into esetshenziswayo ibe yi-liquefied noma i-vaporized state, ethuthukisa izinga lokumuncwa kwe-laser lento futhi izuze ukucutshungulwa okusebenzayo nokusheshayo. Ukukhetha i-laser enobubanzi obuwumgogodla omkhulu kungaholela kalula ekuboniseni okuphezulu. , okuholela ekushiselweni kwe-virtual ngisho nokushiswa kwe-laser;

Izinto ezizwela ukuqhekeka: i-nickel, i-nickel-plated yethusi, i-aluminium, insimbi engagqwali, i-titanium alloy, njll.

Lokhu okuqukethwe ngokuvamile kudinga ukulawulwa okuqinile kwendawo ethinteke ukushisa kanye nechibi elincane lokuncibilika, ngakho-ke kufaneleka kakhulu ukukhetha i-laser encane yobubanzi obuwumgogodla;

(3)I-welding yokungena ejulile idinga ukucutshungulwa kwe-laser ngesivinini esikhulu, futhi kuyadingeka ukukhetha i-laser ene-high density yamandla ukuze kuqinisekiswe ukuthi amandla omugqa anele ukuncibilikisa impahla ngesivinini esikhulu, ikakhulukazi i-lap welding, i-welding yokungena, njll., zidinga ukujula kokungena okuphezulu. Kungcono ukukhetha i-laser encane ye-diameter efanelekile.

2. Izinzuzo kanye nokusetshenziswa kwama-lasers amakhulu obubanzi obuyingqikithi (>100um)

Ububanzi bomnyombo omkhulu nendawo enkulu, indawo enkulu embozwa ukushisa, indawo ebanzi yesenzo, kanye nokuncibilika okuncane kuphela kwendawo yezinto ezibonakalayo kufinyelelwa, okulungele kakhulu ukusetshenziswa ekufakweni kwe-laser, ukuncibilika kwe-laser, ukufakwa kwe-laser, ukuqina kwe-laser, njll. lezi zinkambu, indawo enkulu yokukhanya isho ukusebenza kahle okuphezulu kokukhiqiza kanye namaphutha aphansi (i-thermal conductive welding cishe ayinazo iziphambeko).

Mayelanaukushisela, indawo enkulu isetshenziselwa ikakhulukaziukushisela okuhlanganisiwe, esetshenziselwa ukuhlanganiswa nge-laser encane yobubanzi bomgogodla: indawo enkulu yenza ingaphezulu lezinto ezibonakalayo lincibilike kancane, liguquke lisuka kokuqinile liye oketshezini, okuthuthukisa kakhulu izinga lokumuncwa kwezinto ku-laser, bese isebenzisa umongo omncane le nqubo, ngenxa yokushisisa kwangaphambili kwendawo enkulu, ukucubungula ngemva kokucubungula, kanye nezinga lokushisa elikhulu elinikezwa ichibi elincibilikisiwe, impahla ayijwayele ukuqhekeka okubangelwa ukushisa okusheshayo nokupholisa ngokushesha. Ingenza ukubukeka kwe-weld kube bushelelezi futhi kuzuze i-spatter ephansi kunesixazululo esisodwa se-laser.

Isikhathi sokuthumela: Sep-04-2023