Ukushisela nge-laser kuyindlela ephumelelayo nenembile yokusebenzisa i-laser enamandla amakhulu njengomthombo wokushisa, futhi ingenye yezici ezibalulekile zokusetshenziswa kobuchwepheshe bokucubungula impahla ye-laser. Uyini umehluko phakathi kwe-laser welding kanye ne-welding evamile? Yini okufanele inakwe lapho wenza i-laser welding? I-MAVEN ikulethela uchungechunge lwe-welding laser welding oluphathwayo.

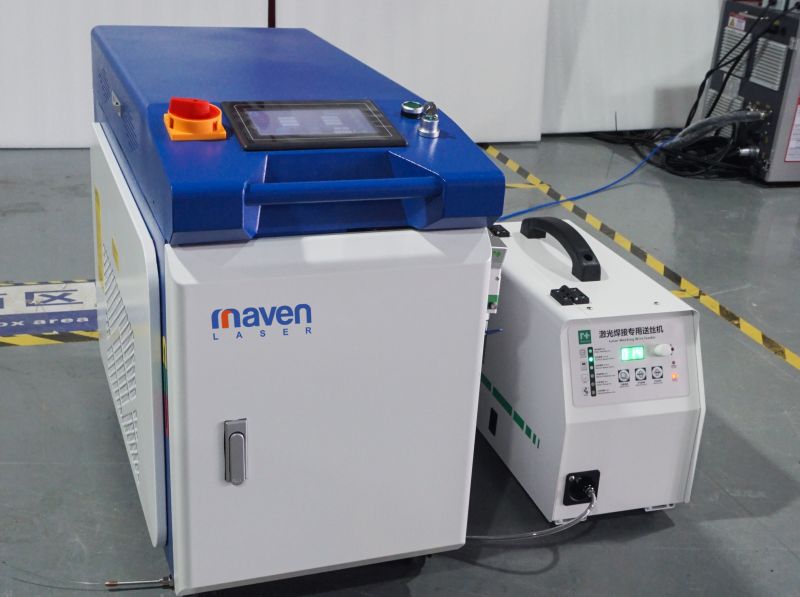

Umshini wokushisela we-laser ophathwa ngesandla usetshenziswa kakhulu ensimbi yeshidi elikhulu neliphakathi nendawo, amakhabethe, i-chassis, umnyango we-aluminium alloy namafreyimu amafasitela, izitsha zokugeza zensimbi engagqwali nezinye izinto zokusebenza ezinkulu ezifana nezikhundla ezingaguquki njengama-engeli angaphakathi kwesokudla, ama-engeli angaphandle kwesokudla, kanye amashisela endiza. Indawo ethintekile ekushiseni incane ngesikhathi sokushisela kanye ne-deformation Encane, futhi ukujula kwe-welding kukhulu, futhi i-welding iqinile. Isetshenziswa kakhulu ekhishini nembonini yokugezela, imboni yemishini yasendlini, imboni yokukhangisa, imboni yesikhunta, imboni yomkhiqizo wensimbi engagqwali, imboni yobunjiniyela bensimbi engagqwali, imboni yomnyango newindi, imboni yezandla, imboni yempahla yasendlini, imboni yefenisha, imboni yezingxenye zezimoto, njll.

Ngakho-ke, yiziphi izinzuzo zemishini yokushisela ye-laser ephathwayo uma iqhathaniswa ne-arc welding njll.?

1.Yonga izindleko zabasebenzi

Uma kuqhathaniswa ne-arc welding, izindleko zokucubungula zingancishiswa cishe ngama-30%. Ukusebenza kulula ukukufunda futhi kuyashesha ukusebenzisa, futhi umkhawulo wobuchwepheshe wama-opharetha awuphezulu. Izisebenzi ezivamile zingaya emsebenzini ngemva kokuqeqeshwa okufushane, futhi zingafinyelela kalula imiphumela yekhwalithi ephezulu yokushisela.

2.Ububanzi obubanzi bokushisela

Ikhanda lomshini wokushisela we-laser eliphathwa ngesandla lifakwe i-5m-10m yasekuqaleni ye-optical fiber, enqoba umkhawulo wesikhala sebhentshi lokusebenzela futhi ingasetshenziselwa ukushisela ngaphandle kanye nokushisela ibanga elide;

3.Kulula ukuyisebenzisa futhi kuyavumelana nezimo

Umshini wokushisela we-laser ophathwa ngesandla ufakwe ama-pulleys ahambayo, okunethezeka ukubamba, futhi isiteshi singalungiswa nganoma yisiphi isikhathi ngaphandle kweziteshi ezigxilile. Imahhala futhi iyavumelana nezimo, futhi ifanele izimo ezihlukahlukene zendawo yokusebenza.

4.Akukho okudlekayo kokushisela

Umsebenzi wokushisela ezingqondweni zabantu abaningi "izibuko esandleni sobunxele kanye nocingo lokushisela esandleni sokudla". Nokho, ngomshini we-laser welding ophethwe ngesandla, ukushisela kungaqedwa kalula, okunciphisa izindleko zezinto zokukhiqiza nokucubungula.

5.Inezaziso eziningi zokuphepha

I-touch switch isebenza kuphela lapho ithiphu yokushisela ithinta insimbi, futhi ukukhanya kuzokhiywa ngokuzenzakalelayo ngemva kokukhipha ucezu lokusebenza, futhi inkinobho yokuthinta inenzwa yokushisa komzimba. Ukuphepha okuphezulu, ukuqinisekisa ukuphepha komsebenzisi ngesikhathi somsebenzi.

6.Izindlela zokushisela ezihlukahlukene

Ingakwazi ukubona ukushisela kunoma iyiphi i-engeli: i-stitch welding, i-butt welding, i-welding ye-butt, i-welding eqondile, i-flat fillet welding, i-internal fillet welding, i-outer fillet welding, njll. Bona ukushisela kunoma iyiphi i-engeli. Ngaphezu kwalokho, angakwazi futhi ukuqedela ukusika, i-welding kanye nokusika kungashintshwa ngokukhululekile, vele uguqule i-nozzle ye-welding yethusi ku-nozzle yethusi yokusika, elula kakhulu.

7.Ama-welds awadingi ukugaya

Ngemuva kwe-welding yendabuko, iphoyinti lokushisela lidinga ukupholishwa ukuze kuqinisekiswe ubushelelezi hhayi ubulukhuni. Umshini wokushisela we-laser ophathwa ngesandla uvele ubonise izinzuzo ezengeziwe kumphumela wokucubungula: ukushisela okuqhubekayo, izikali ezibushelelezi futhi ezingenazo izinhlanzi, ezinhle futhi ezingenazo izibazi, inqubo yokugaya yokulandelela kancane.

8.Umphumela omuhle we-welding

Umshini wokushisela we-laser ophathwa ngesandla uyi-hot-melt welding. Uma kuqhathaniswa ne-welding yendabuko, i-laser welding inomthamo omkhulu wamandla futhi ingafinyelela imiphumela engcono yokushisela. Indawo yokushisela inethonya elincane elishisayo, akulula ukukhubaza, ukumnyama, futhi kukhona iminonjana emhlane, futhi ukujula kwe-welding kukhulu. , ukuncibilika okugcwele, okuqinile futhi okuthembekile, amandla we-weld afinyelela noma adlule ngisho nesisekelo sensimbi ngokwayo, esingenakuqinisekiswa ngemishini evamile yokushisela.

I-welding ebanjwa ngesandla ihloselwe kakhulu ukushisela nge-laser yezindawo ezikude nezinkulu zokusebenza. Inqoba umkhawulo wendawo yokuhamba yebhentshi lokusebenzela. Indawo ethintekile ekushiseni incane ngesikhathi sokushisela, okungeke kubangele ukuguqulwa komsebenzi, ubumnyama, kanye nemikhondo ngemuva. Ngaphezu kwalokho, ukujula Welding kukhulu kanye Welding Firm futhi elincibilike ngokugcwele, ayikwazi nje ukubona ukushisa conduction Welding, kodwa futhi okuqhubekayo ngokujulile Ukungena Welding, indawo Welding, Butt Welding, lap Welding, sealing Welding, Seam Welding, njll.

Umshini wokushisela we-laser ophathwa ngesandla ugcwalisa igebe endaweni yokushisela ebanjwe ngesandla embonini yemishini ye-laser, uphazamisa imodi yokusebenza yomshini wokushisela we-laser wendabuko, futhi ungafaka esikhundleni sendlela yangaphambilini egxilile yokukhanya ngomshini obanjwa ngesandla. Iguquguquka kakhudlwana futhi elula, futhi ibanga lokushisela lide, okwenza futhi ukusebenza kwe-laser welding ngaphandle kwenzeke.

Isikhathi sokuthumela: Aug-25-2023