1.Izinzuzo kanye nokubi komshini wokushisela we-laser kanye nobubanzi bokusebenza kwawo

Umshini wokushisela we-laser uwuhlobo olusha lwendlela yokushisela, enamandla ebhondi ephansi, indawo ethinteke ngokushisa ebanzi kanye nezinye izinzuzo eziningi, emakethe yamanje yokucubungula insimbi, i-laser welding isetshenziswe kabanzi kakhulu, sekuyisikhathi eside isetshenziswa kuzo zonke izigaba zokuphila. , njengokuthi: inkomishi yokufaka insimbi, imboni yomakhalekhukhwini, imboni yezokwelapha, imboni yezimoto neminye imikhakha eminingi yezimboni.

01 Izinzuzo zomshini wokushisela we-laser

Uma kuqhathaniswa nobuchwepheshe bendabuko bokushisela, ubuchwepheshe be-laser welding abuyona i-welding yokuxhumana, inqubo yokusebenza ayidingi ingcindezi, inesivinini esisheshayo sokushisela, amandla aphezulu, ukujula, ukuguqulwa okuncane, i-weld seam emincane, indawo encane ethintekile ukushisa, kanye nendawo yokusebenza. i-deformation incane, umthwalo wokucubungula olandelwayo uncane, unciphisa okukhipha ngesandla, ukuguquguquka okuphezulu, ukuphepha okwengeziwe nezinye izinzuzo.

Ubuchwepheshe bokushisela nge-laser bungasetshenziselwa ukushisela izinto eziphikisayo njengezinsimbi ezincibilika phezulu, ngisho nezinto ezingezona ezensimbi ezifana ne-ceramics nengilazi ye-organic, enemiphumela emihle yokushisela ezintweni ezibunjiwe kanye nokuguquguquka okukhulu. Ukuze uthole izingxenye ezingafinyeleleki zokushisela, ukushisela okuguquguqukayo okungathintana naye kuyenziwa. I-laser beam ingahlukaniswa ngesikhathi namandla, ivumele ukucubungula ngesikhathi esisodwa kwemishayo eminingi, inikeze izimo zokushisela okunembe kakhudlwana.

02 Amaphuzu okufanele uwaqaphele ngokusetshenziswa kwemishini yokushisela i-laser

Izici ezilandelayo kufanele ziqashelwe lapho kusetshenziswa imishini yomshini wokushisela we-laser

(a) Indawo yengxenye eshiselwe idinga ukunemba kakhulu, uqiniseke ukuthi ingaphakathi kokugxilwe kukho kwe-laser beam.

(b) Uma ingxenye eshiselwe idinga ukusetshenziswa kwento ethile, kufanele kuqinisekiswe ukuthi indawo yokugcina yengxenye eshiselwe idinga ukuhambisana nendawo yokushisela lapho ugongolo lwe-laser luzothinta khona.

(c) Ubukhulu obukhulu obushiselayo bunomkhawulo, ukungena kwezingcezu zokusebenza ezinogqinsi olungaphezu kuka-19mm emugqeni wokukhiqiza kudinga ukubonisana nomkhiqizi ukuze anikeze ukwesekwa kobuchwepheshe okwengeziwe.

03 Izicelo zemishini yokushisela i-laser

1. Imboni yebhethri

Umakhalekhukhwini kanye neningi lemikhiqizo yekhodi yebhethri kusetshenziswa i-laser welding.

2. Bathroom kitchenware industry

Ukunemba kwe-laser welding kunokubukeka okungcono, ngakho-ke endaweni yokugezela yensimbi engagqwali imikhiqizo ye-laser yokumaka i-laser welding inezinhlobonhlobo zezicelo. Okufana nalokhu: izibambo, ompompi, imimese yokusika engagqwali futhi iningi lendlela ngokumaka nge-laser kokukhiqizwa kwe-LOGO yezinkampani, amaketela kagesi wezinga eliphezulu nezinye izimpawu nazo zisebenzisa i-laser welding ukuze ziqedele. Impahla yasekhishini, i-tableware yeqembu i-welding butt welding, i-mold mold evulekile ukwenza nokulungisa futhi ushintshe isikhunta ngesikhathi sokusetshenziswa.

3. Imikhiqizo yedijithali, omakhalekhukhwini, imboni yamakhompyutha

Ukucutshungulwa kwe-laser ngenxa yobuchwepheshe bokucubungula ukunemba, kwedijithali, umakhalekhukhwini, izinhlelo zokusebenza zenkundla yekhompiyutha ezidume kakhulu njengalezi: omakhalekhukhwini, i-MP4, i-MP3 igobolondo le-laser welding, umugqa wesixhumi esibonakalayo, amakhompyutha aphathekayo, amadivaysi e-fiber optic indawo yokushisela, ukushisela kwe-chassis yekhompyutha .

4. Imboni yemishini yobunjiniyela

Imishini yokuhlanza i-welding, izingxenye ze-electromechanical welding, isixhumi esithwala ukukhanda.

5. Ezogesi, imboni kagesi

Njengoba ukucutshungulwa kwe-laser kuyindlela yokucubungula okungathinteki, akukhiqizi i-extrusion yemishini noma ukucindezeleka komshini, ngakho-ke kuhlangabezana nezidingo zokucubungula zemboni ye-elekthronikhi. Okufana nalokhu: ama-transformer, ama-inductors, izixhumi, amatheminali, izixhumi ze-fiber optic, izinzwa, ama-switchers, amaswishi, amabhethri omakhalekhukhwini, izakhi ze-microelectronic, imikhondo yesekethe edidiyelwe nokunye ukushisela.

6. Imboni yobucwebe

Njengoba ukucubungula kwe-laser kuhle kakhulu, ilungele imikhiqizo eyigugu nemincane embonini yobucwebe. Njengoba i-laser focused beam inhle kakhulu, ikhuliswa ngesibonakhulu ukuze ikhulise izingxenye ezincane zobucwebe futhi ibone ukushisela okunembayo. I-laser spot welder iyisisetshenziswa esidingekayo sokuxhumanisa amaketanga obucwebe kanye nokufakwa kwamatshe ayigugu.

7. Izingxenyekazi zekhompuyutha, amathuluzi, imboni yezinsimbi

Insimbi, inzwa, i-kitchenware, i-tableware group welding butt welding, ukuvula nokulungisa isikhunta kanye nokushintsha isikhunta ngesikhathi sokusetshenziswa. I-welding engenamthungo ye-stainless steel tableware, i-welding ekuxhumekeni kwe-meter core.

8. Imboni yezimoto, yezimoto zikagesi

Ukucutshungulwa kwe-laser kokucutshungulwa okungekona othintana naye, akukho ukungcoliswa komkhiqizo, isivinini esikhulu, okufanelekela kangcono izidingo zenqubo yokukhiqiza izimpahla ezithengwayo zezimoto ezisezingeni eliphezulu, njengokushisela ukudayela kwezimoto, ukushisela i-valve, ukushisela indandatho ye-piston, ukushisela isilinda se-automotive gasket, ipayipi lokukhipha, i-welding yokuhlunga, i-welding ye-generator yegesi yokuphepha kwezimoto. Ukusika izingxenye ze-laser esivivinyweni kanye nesiteji sokukhiqiza inqwaba yezimoto, kanye nokushiselwa kwamabhethri ezimotweni zikagesi.

9. Imboni yezinto zokwakha zokukhanyisa amandla

Ukucutshungulwa kwe-laser kusetshenziswa kabanzi ekukhiqizeni amaseli elanga elanga: njengokusika i-solar silicon wafer laser scribing, i-solar water heater heat conduction plate welding. Ukucutshungulwa kwe-Laser, njengendlela yokucubungula imvelo nesebenzayo, kuzosetshenziswa kabanzi esikhathini esizayo.

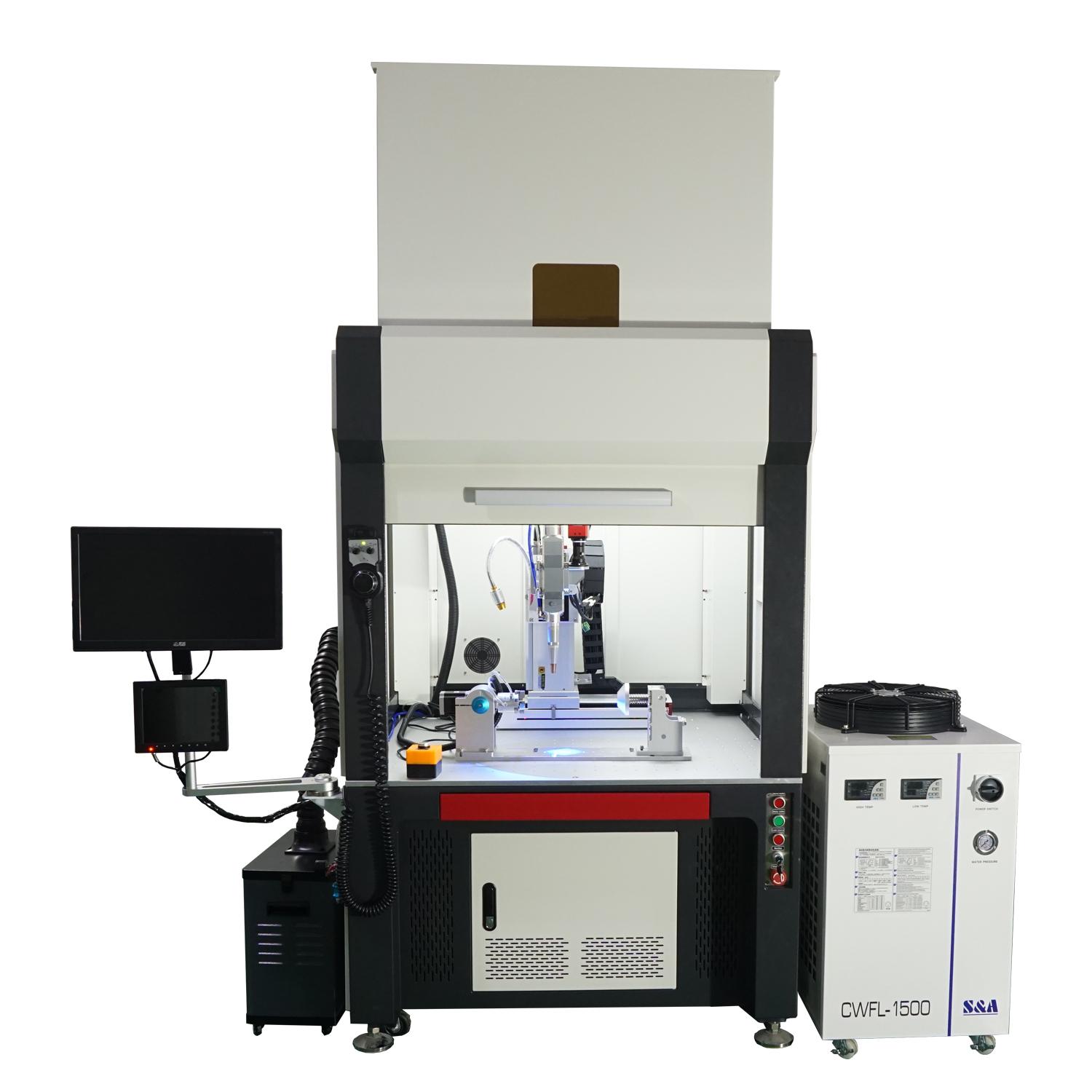

2.Yini i-Platform othomathikhi laser welding umshini?

Umshini wokushisela we-laser othomathikhi we-Platform uwumshini wokushisela othomathikhi osebenzisa ama-laser pulses enamandla kakhulu ukuze ushise izinto endaweni encane. Amandla emisebe ye-laser asakazwa ngokuqhutshwa kokushisa ukuya ngaphakathi kwempahla futhi impahla iyancibilika ukuze yakhe ichibi elithile elincibilikisiwe. Ikakhulukazi isetshenziselwa ukushisela izinto ezinodonga oluncane kanye nezingxenye ezinembayo, futhi ingakwazi ukubona ukushisela ngogesi, ukushisela izinqe, i-lap welding, i-seal welding, njll. Inezici zobubanzi obuncane bokushisela, isivinini sokushisela okusheshayo, ikhwalithi ephezulu yokushisela, akukho i-porosity, ukulawula okunembile, ukunemba kokuma okuphezulu, kanye ne-automation elula.

3.Uyini umshini wokushisela we-laser ophathwa ngesandla?

Njengoba igama lisho, umshini we-laser welding manual uwuhlobo lwemishini yokushisela edinga ukusebenza ngesandla. Lo mshini wokushisela ungenza i-laser welding kuma-workpieces amade namakhulu. Lapho i-welding, indawo ethintekile ekushiseni incane futhi ayibangeli ukuguquguquka, i-blackening kanye namamaki ngemuva kwendawo yokusebenza. Ukujula kwe-welding kukhulu, i-welding iqinile, ukuncibilika kwanele, futhi akukho ukucindezeleka echibini lokuncibilika lapho ukuboniswa kwezinto ezincibilikisiwe kuhlangana ne-substrate.

4.Uyini umehluko phakathi komshini wokushisela we-laser othomathikhi kanye nomshini wokushisela we-laser ophathwayo?

Imishini yokushisela i-laser ezenzakalelayo ishisela ngokuzenzakalelayo ngokohlelo olumisiwe ngemva kokusetha kusofthiwe; imishini yokushisela i-laser manual, eyaziwa nangokuthi i-spot welding, isetshenziswa abasebenzisi uma besebenzisa imishini yokushisela i-laser ngokukhuliswa okuphezulu esikrinini.

I-Visual spot welding yenziwa mathupha futhi ngokuvamile ngokwezifiso ekhiqizwa abakhiqizi bemishini ye-laser ukuze kuhlangatshezwane nezidingo zomsebenzisi. Bambalwa abakhiqizi abanezinto zesitoko. Uma izinto zesitoko zitholakala, zinikezwa umsebenzisi njenge-prototype noma ireferensi yokuqinisekisa. Okubaluleke nakakhulu, amandla nezici zemishini yokushisela kunqunywa ngokubonisana nomsebenzisi, futhi kufanele futhi sinikeze umsebenzisi umkhiqizo wempahla engabizi kakhulu ngokusekelwe ezindlekweni zokuthenga. Kukusiphi isimo kungcono ukusebenzisa umshini wokushisela we-laser manual, uma kuqhathaniswa nomshini wokushisela we-laser ozenzakalelayo, akukhona nje kuphela ukuthi izindleko zokuthenga ziphezulu, kodwa izindleko zokulondoloza nazo ziphezulu kakhulu. Uma into enembe kakhulu ibaluleke kakhulu ekunakekeleni futhi ngokwemvelo izindleko ziphezulu. Ngaphezu kwalokho, ukushiswa kwe-laser okuzenzakalelayo ngokugcwele kugxile kakhulu ku-automation ye-CNC yesikhulumi somsebenzi, okudinga ukusebenza okuphezulu nokuguquguquka kwesiteji somsebenzi, kodwa ngokusebenza, lokhu akuyona i-panacea, futhi ukushintsha okuningi kwemikhiqizo ehlukene ayikwazi ukusetshenziswa, okuyinto. ikhawulela indima yomshini wokushisela we-laser othomathikhi. Namuhla, sigxila emshinini we-laser welding manual, ngakho-ke idivayisi yezandla ixazulula izinkinga ezingenhla ngokwemvelo. Umsebenzi wayo wokushisela ukwenza umsebenzi wokushisela ngokuhlanganyela kwe-laser welding ephathwayo enama-engeli okulawula ahlukahlukene, ngakho-ke kungathiwa umshini we-laser ongeyona inkambiso ukuze uvumelane nokushiselwa kobumo nama-engeli amaningi wemikhiqizo. Uma nje amandla aphezulu ngokwanele, angakwazi ukuzivumelanisa nokushisela kwemikhiqizo eminingi

Ukukhiqizwa kwemishini yokushisela i-laser ye-manual kuphansi kakhulu kunaleyo yemishini ezenzakalelayo. Kodwa-ke, ukucutshungulwa kokusabalalisa noma ukucubungula okungezona okukhulu kanye nokushisela izitshalo zokukhiqiza, ukushisela i-laser manual kunenzuzo enkulu. Asikho isidingo sokumisa itafula le-welding futhi ugweme inkinga yesikhala esikhulu sesitezi. Ngaphezu kwalokho, ama-workshops amancane ashisela imikhiqizo ehlukahlukene enezimo ezingavamile, ngakho-ke i-laser welding manual ingahlangabezana ngokugcwele nezidingo zokukhiqiza okunjalo futhi ikwazi ukuzivumelanisa nezimo.

I-laser welding ye-manual ngaphandle kwetafula le-welding elinembile, ukusetshenziswa okuphansi kwezinto ezisetshenziswayo kanye nezindleko eziphansi zokugcinwa kwemishini. Ngokuvamile, sidinga ukugcina amabhentshi okusebenza engeziwe, kuyilapho okokusebenza kwelaser okwenziwa ngesandla kungaqeda ukusebenza inqobo nje uma kufakwe amajoyinti okushisela e-laser aphathwayo. Kulula ukufaka esikhundleni, izindleko eziphansi zokushintshwa kwezingxenye. Uma ungazi ukuthi ungawashintsha kanjani, ungawanikeza umenzi ukuze anakekele ngqo ngaphandle kokukhathazeka ngokuthunyelwa.

Umehluko phakathi kwemishini yokushisela i-laser othomathikhi nemishini yokushisela ye-laser manual kwabelwana ngayo lapha. Abantu abaningi bangase bacabange ukuthi i-laser welder ezenzakalelayo ingcono ngoba i-othomathikhi, kodwa iqiniso liwukuthi lezi zinhlobo ezimbili zemishini zisetshenziselwa izinhloso ezahlukene futhi ngayinye inezinzuzo zayo. Enqubweni yokukhetha, sidinga futhi ukukhetha imishini yokushisela ye-laser efanele yokukhiqiza kwethu ngokwezidingo zethu zangempela.

Isikhathi sokuthumela: Feb-01-2023